Method for preparing villiaumite and lithium salt by using high-lithium electrolyte

A technology of electrolyte and lithium salt, which is applied in the field of aluminum electrolyte recycling, can solve the problems of low molecular ratio of recycled cryolite, low electrolyte molecule, shrinking cryolite market demand, etc., and achieve the effect of high recovery rate and large market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

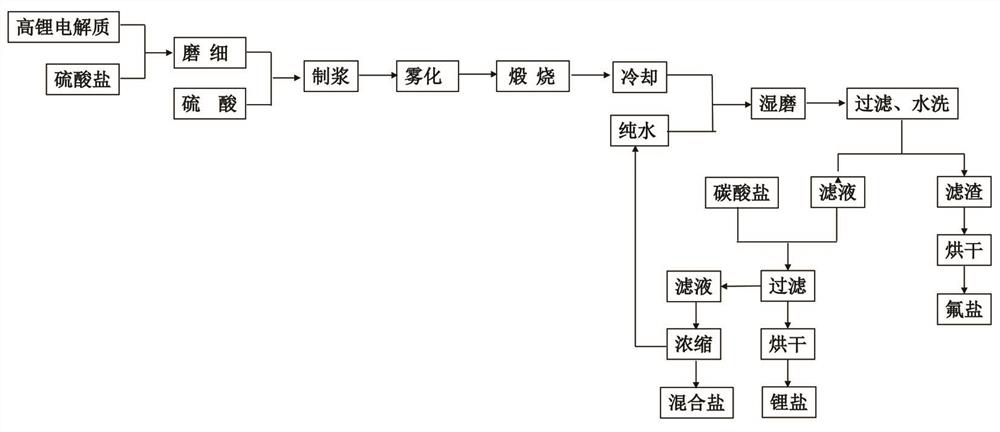

[0042] This embodiment provides a method for preparing fluorine salts and lithium salts using high-lithium electrolytes, including:

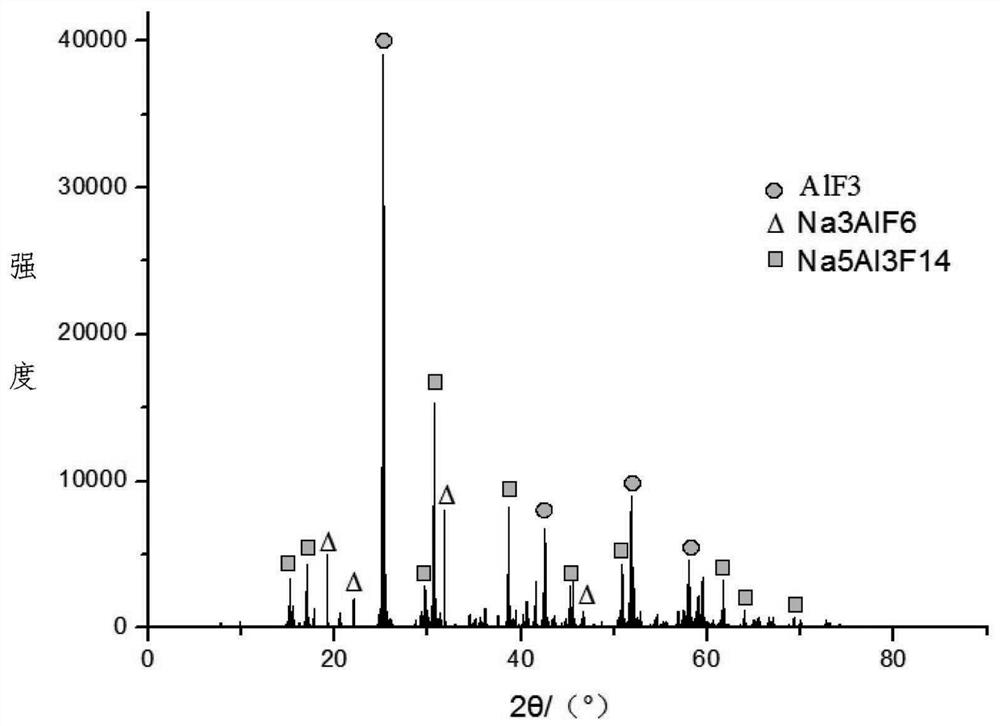

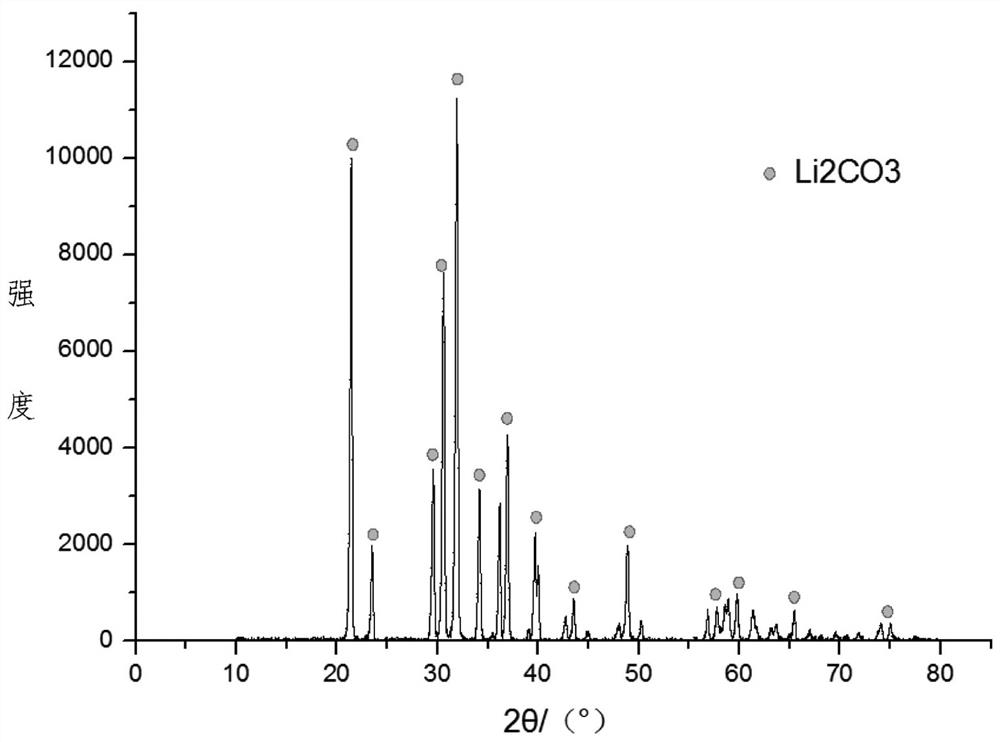

[0043] First take 100 kg of electrolyte particles with a particle size of less than 25 mm and 80 kg of aluminum sulfate in a ball mill and grind them to 300 mesh, and then mix them uniformly with 150 kg of sulfuric acid with a mass fraction of 5% to make a raw material mixed slurry, wherein the electrolyte particles including Na 3 AlF 6 Content 76%, Na 5 al 3 f 14 8% content, 8% LiF content, 2% C content, CaF 2 Content 3.2%, Al 2 o 3 content of 2.8%; the mixed slurry of the raw materials was atomized to a particle size of less than 120 μm, sprayed into a rotary furnace, calcined at 500°C for 2 h, added 320 kg of pure water after cooling, and wet-milled to less than 200 mesh. Dry at 500°C to obtain 75 kg of fluorine salt mixture; use XRD semi-quantitative analysis to detect and analyze the composition of the fluoride salt mixture, the resu...

Embodiment 2

[0047] This embodiment provides a method for preparing fluoride salts and lithium salts using high-lithium electrolytes, which includes: first taking 1000 kg of electrolyte particles with a particle size of less than 25 mm and 1500 kg of aluminum sulfate octadecahydrate into a ball mill, mixing and grinding to 400 mesh, Then it is uniformly mixed with 1200 kg of sulfuric acid with a mass fraction of 30% to make a raw material mixed slurry, wherein the electrolyte particles include Na 3 AlF 6 Content 80%, Na 5 al 3 f 14 6% content, 4% LiF content, 2.5% C content, CaF 2 Content 2.5%, Al 2 o 3 Content 5%; atomize the mixed slurry of the raw materials to a particle size of less than 150 μm, spray it into a rotary furnace, calcinate at 600°C for 5 hours, add 1600kg of pure water after cooling, wet grind to less than 200 mesh, and dry the filtered residue at 500°C , obtain 780 kg fluorine salt mixture, adopt XRD semi-quantitative analysis method to detect and analyze the compo...

Embodiment 3

[0051] This example provides a method for preparing fluoride salts and lithium salts using high-lithium electrolytes, including: first take 500 kg of electrolyte particles with a particle size of less than 25 mm, 350 kg of sodium sulfate and 350 kg of aluminum sulfate, add them to a ball mill, mix and grind to 400 mesh , and then uniformly mixed with 250 kg of sulfuric acid solution with a mass fraction of 50% to make a raw material mixed slurry, wherein the electrolyte particles include Na 3 AlF 6 Content 74%, Na 5 al 3 f 14 7% content, 10% LiF content, 2.5% C content, CaF 2 Content 3.2%, Al 2 o 3 content of 3.3%; the mixed slurry of the raw materials is atomized to a particle size of less than 150 μm, sprayed into a rotary furnace, calcined at 550°C for 1 h, cooled and then added with 1500 kg of pure water, and wet-milled to a size of less than 200 mesh. Dry at 550°C to obtain 315 kg of fluorine salt mixture. The composition of the fluoride salt mixture is detected and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com