Preparation method and application of vinasse alcohol-soluble peptide

A distiller's grains and alcohol-soluble technology, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problem that peptide powder cannot be added directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

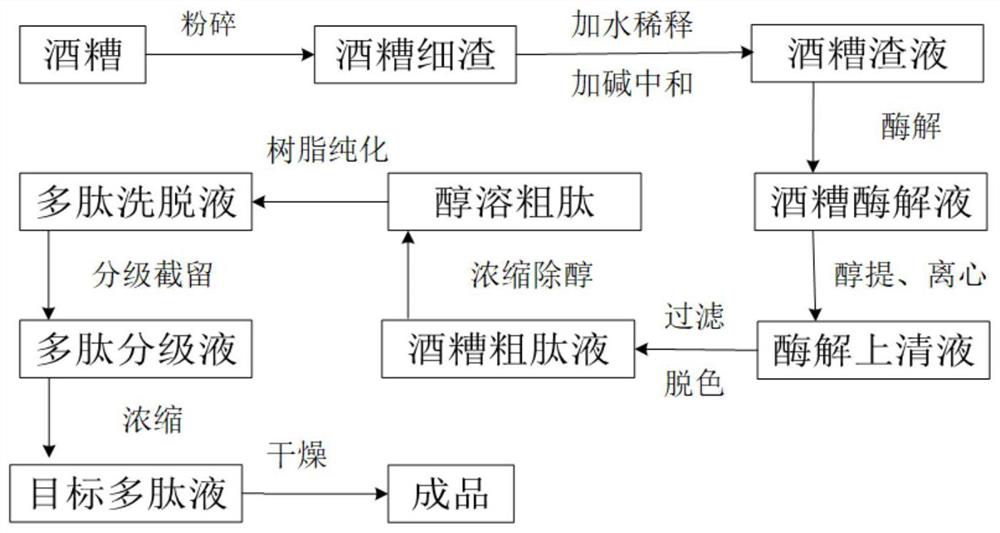

Method used

Image

Examples

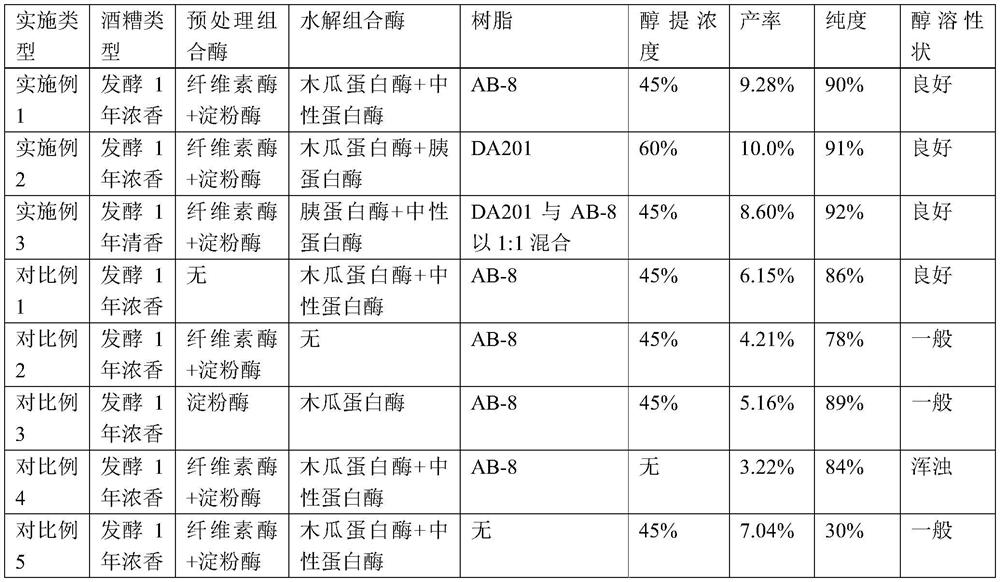

Embodiment 1

[0034] Take 1000g of Luzhou-flavored distiller's grains fermented for 1 year, dilute with 3 times the mass of water after crushing, and the crude protein concentration in the system reaches 5.2g / 1000ml. Adding 4g NaOH to the mixed system to adjust the pH is 7.0, and then adding pretreatment combined enzymes (1g cellulase+1g amylase at the same time, wherein the enzyme activity of amylase is 4000U / g, and the enzyme activity of cellulase is 10000U / g, the same below) and hydrolysis combination enzyme (1g papain+1g neutral protease, wherein, the enzyme activity of papain is 60000U / g, the enzyme activity of neutral protease is 50000U / g, the same below), stirred at 50 ℃ Enzymatic hydrolysis for 3 hours. After enzymatic hydrolysis, add 3 times the volume of 45% ethanol to stir for 15 minutes, then alcohol precipitation for 12 hours, centrifuge at 4000rpm for 30 minutes, take the supernatant, discard the residue, and the content of alcohol-soluble crude peptide in the supernatant aft...

Embodiment 2

[0036] Take 1000g of Luzhou-flavor distiller's grains fermented for 1 year, dilute with 3 times the quality of water after crushing, and the crude protein concentration in the system reaches 5.2g / 1000ml. Add 4g NaOH to the mixed system to adjust the pH to 7.0, add pretreatment combination enzyme (1g amylase+1g cellulase) and hydrolysis combination enzyme (1g papain+1g trypsin, wherein the enzyme activity of trypsin is 10000U / g, the same below), stirred at 50°C for 3 hours. After enzymatic hydrolysis, add 3 times the volume of 60% ethanol and stir for 15 minutes, then alcohol precipitation for 12 hours, centrifuge at 4000rpm for 30 minutes, take the supernatant, discard the residue, and the content of alcohol-soluble crude peptide in the supernatant after two extractions is 1.9g / 1000ml. Add 2% activated carbon and 1% diatomaceous earth to the supernatant successively to filter and concentrate under reduced pressure until the volume is 500ml. Take 10g macroporous resin DA201 ...

Embodiment 3

[0038]Take 1000g of Fen-flavor distiller's grains that have been fermented for 1 year, grind them and dilute with 3 times the quality of water, and the concentration of crude protein in the system will reach 2.1g / 1000ml. Add 3.6g NaOH to the mixed system to adjust the pH to 7.0, add pretreatment combination enzyme (1g amylase + 1g cellulase) and hydrolysis combination enzyme (1g neutral protease + 1g trypsin), stir at 50°C for enzymolysis 3 Hour. After the enzymatic hydrolysis, add 3 times the volume of 45% ethanol to stir for 15 minutes, then alcohol precipitation for 12 hours, centrifuge at 4000rpm for 30 minutes, take the supernatant, discard the residue, and the alcohol-soluble crude peptide content in the supernatant after two extractions is 1.06g / 1000ml. Add 2% activated carbon and 1% diatomaceous earth to the supernatant successively to filter and then concentrate under reduced pressure until the volume is 500ml. Take 10g of macroporous resin AB-8 and DA201 and mix (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com