Metal reinforced porous diamond film and preparation method thereof

A diamond film and metal strengthening technology, which is applied in metal material coating process, gaseous chemical plating, ion implantation plating, etc., can solve the problems of micro-cracks and small cavities, high equipment cost, and defect expansion, etc., to improve surface adsorption Performance, method simplicity, combined strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

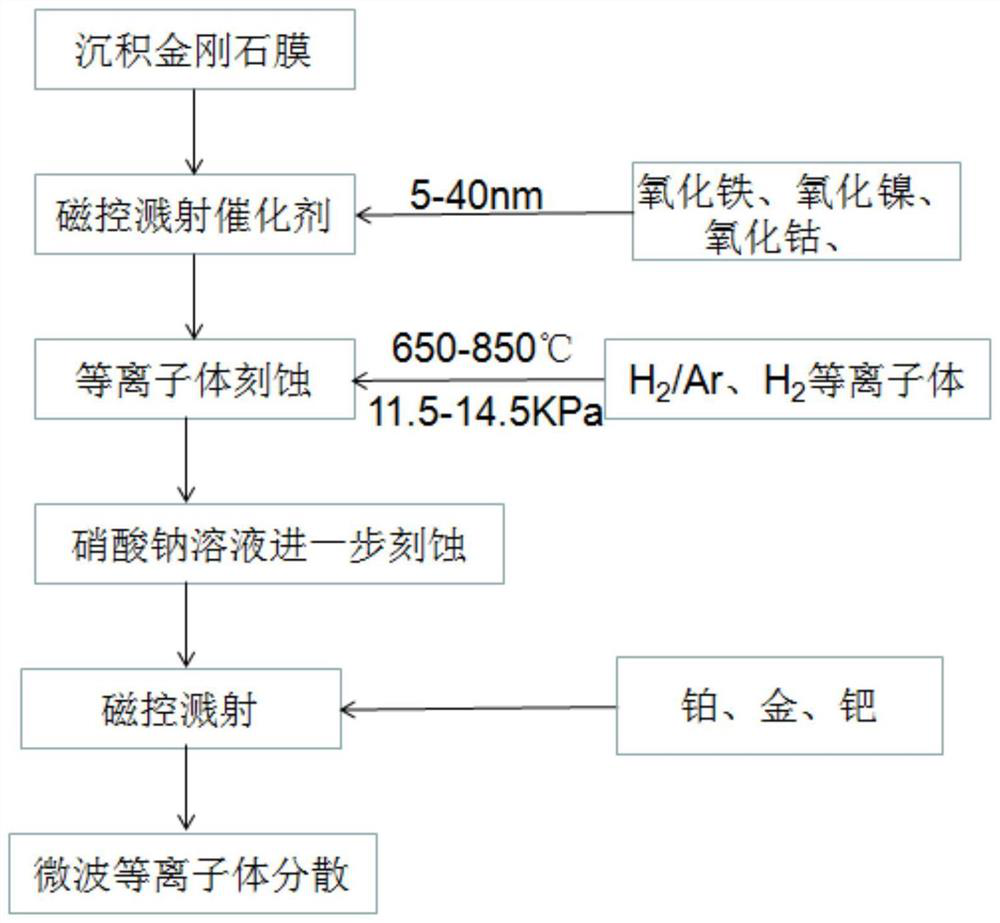

Method used

Image

Examples

Embodiment 1

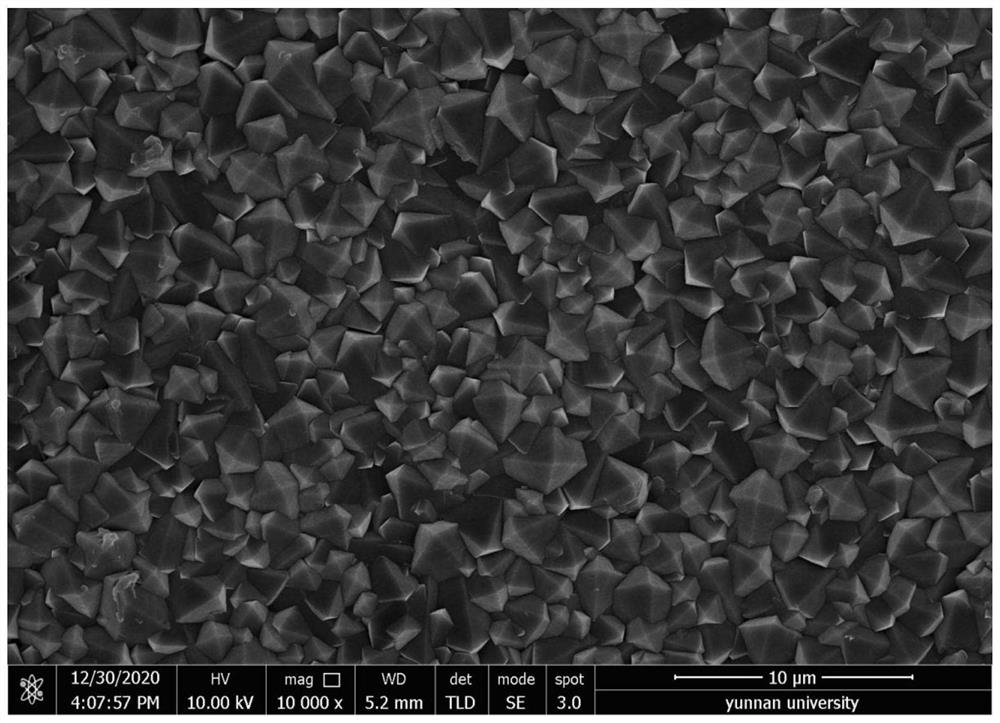

[0040] Step 1: Pre-polish the silicon substrate, put the polished substrate into the diamond suspension and ultrasonically treat it for 30 minutes, then wash it with alcohol and deionized water in sequence, dry it with dry air, put it in Microwave chemical vapor deposition system, the pressure of the reaction chamber is pumped to 0.1KPa, and then 380sccm hydrogen gas is introduced. After the pressure reaches about 2KPa, the microwave system is turned on. After the plasma ball appears, the pressure is adjusted to 13KPa, the temperature is 850°C, and 11sccm hydrogen gas is introduced. Methane was deposited for 5 hours to obtain a diamond film with a thickness of 8 μm on the surface of the silicon substrate.

[0041] Step 2: Magnetron sputtering iron oxide with a thickness of 15 nm on the deposited diamond film to form a dense film.

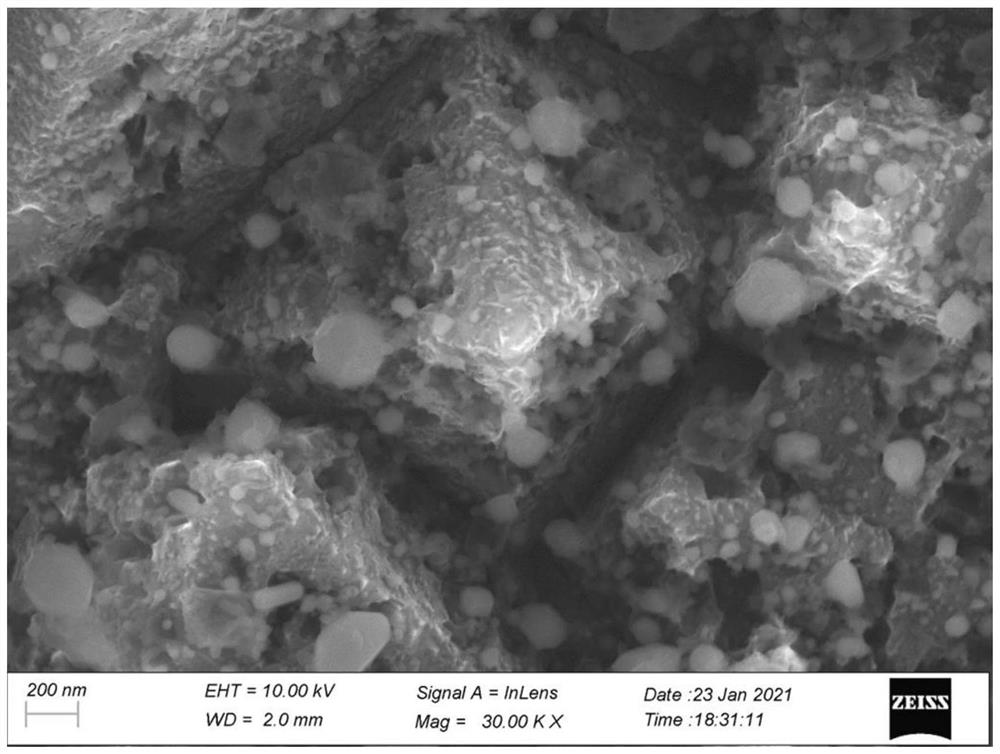

[0042]Step 3: Put the diamond film with a layer of nano-oxide deposited on the surface obtained in step 2 into a microwave chemical vapor depositio...

Embodiment 2

[0047] Step 1: Pre-polish the silicon substrate, put the polished substrate into the diamond suspension and ultrasonically treat it for 20 minutes, then wash it with alcohol and deionized water in sequence, dry it with dry air, put it in Microwave chemical vapor deposition system, the pressure of the reaction chamber is pumped to 0.1KPa, and then 360sccm hydrogen gas is introduced. After the pressure reaches about 2KPa, the microwave system is turned on. After the plasma ball appears, the pressure is adjusted to 12KPa, the temperature is 850°C, and 10sccm is injected. Methane was deposited for 5 hours to obtain a diamond film with a thickness of 5.5 μm on the surface of the silicon substrate.

[0048] Step 2: Magnetron sputtering nickel oxide with a thickness of 5 nm on the deposited diamond film to form a dense film.

[0049] Step 3: Put the diamond film with a layer of nano-oxide deposited on the surface obtained in step 2 into a microwave chemical vapor deposition system, f...

Embodiment 3

[0054] Step 1: Pre-polish the silicon substrate, put the polished substrate into the diamond suspension and ultrasonically treat it for 40 minutes, then wash it with alcohol and deionized water in sequence, dry it with dry air, put it in Microwave chemical vapor deposition system, the pressure of the reaction chamber is pumped to 0.1KPa, and then 400sccm hydrogen gas is introduced. After the pressure reaches about 2KPa, the microwave system is turned on. After the plasma ball appears, the pressure is adjusted to 14KPa, the temperature is 850°C, and 12sccm is introduced. Methane was deposited for 5 hours to obtain a diamond film with a thickness of 10 μm on the surface of the silicon substrate.

[0055] Step 2: Magnetron sputtering cobalt oxide with a thickness of 40 nm on the deposited diamond film to form a dense film.

[0056] Step 3: Put the diamond film with a layer of nano-oxide deposited on the surface obtained in step 2 into a microwave chemical vapor deposition system,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com