Oxygen-rich vacancy type black phosphorus quantum dot/bismuth oxycarbonate visible light catalyst and preparation method and application

A technology of bismuth oxycarbonate and quantum dots, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low absorption efficiency, achieve effective quality improvement, high efficiency, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

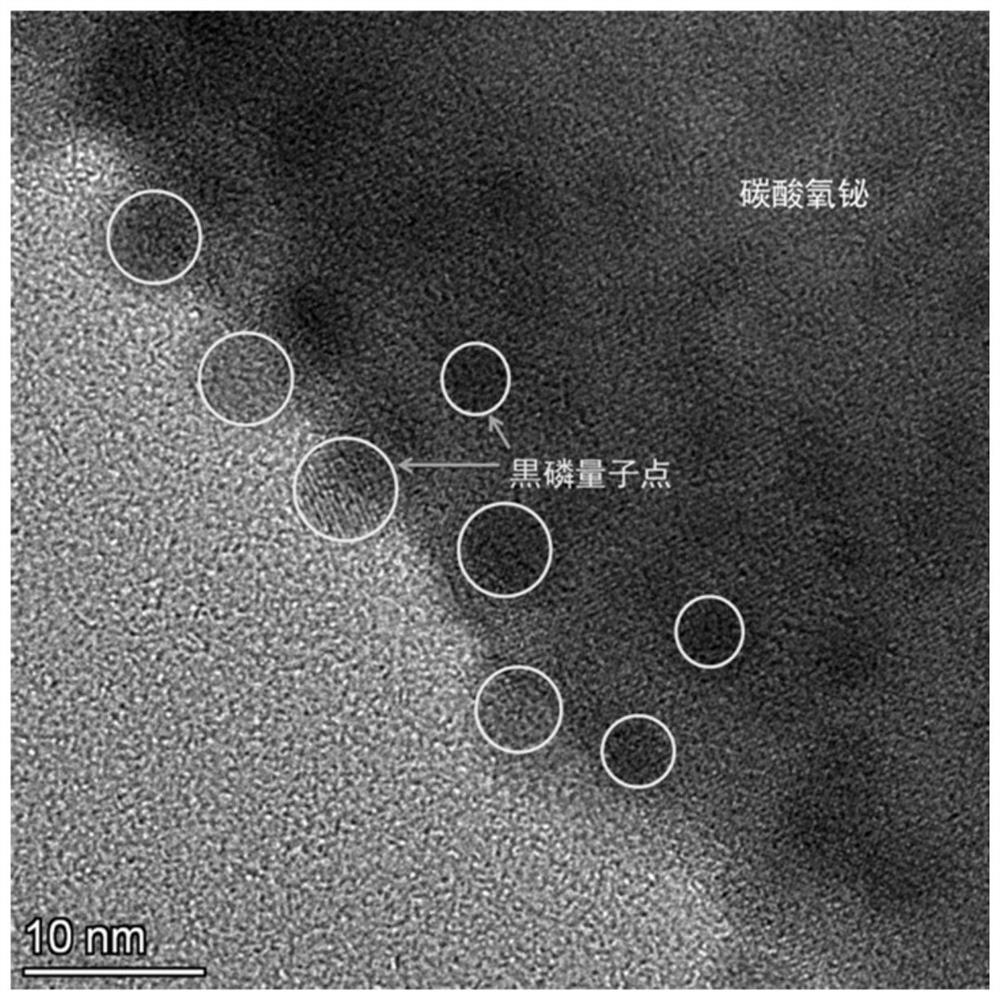

[0022] A preparation method of an oxygen-enriched vacancy type black phosphorus quantum dot / bismuth oxycarbonate visible light catalyst of the present invention comprises the following steps:

[0023] (1) Preparation of black phosphorus quantum dots:

[0024] Weigh black phosphorus and sodium hydroxide in a glove box, add deoxygenated absolute ethanol, seal them in an agate cup, and grind them with a ball mill at 300-600 rpm for 3-9 hours. Then transfer it into a round-bottomed flask, add a certain volume of deoxygenated absolute ethanol, heat the solvent under nitrogen bubbling at 80-120 °C for 4-16 h, and cool to room temperature naturally to obtain a black phosphorus quantum dot solution. Among them, the mass ratio of black phosphorus crystal to sodium hydroxide is 1:(0.5~15).

[0025] (2) Preparation of oxygen-rich vacancy black phosphorus quantum dots / bismuth oxycarbonate:

[0026] The nano-flaky bismuth oxycarbonate is treated with a flow rate of 30-50mL / min in a reduc...

Embodiment 1

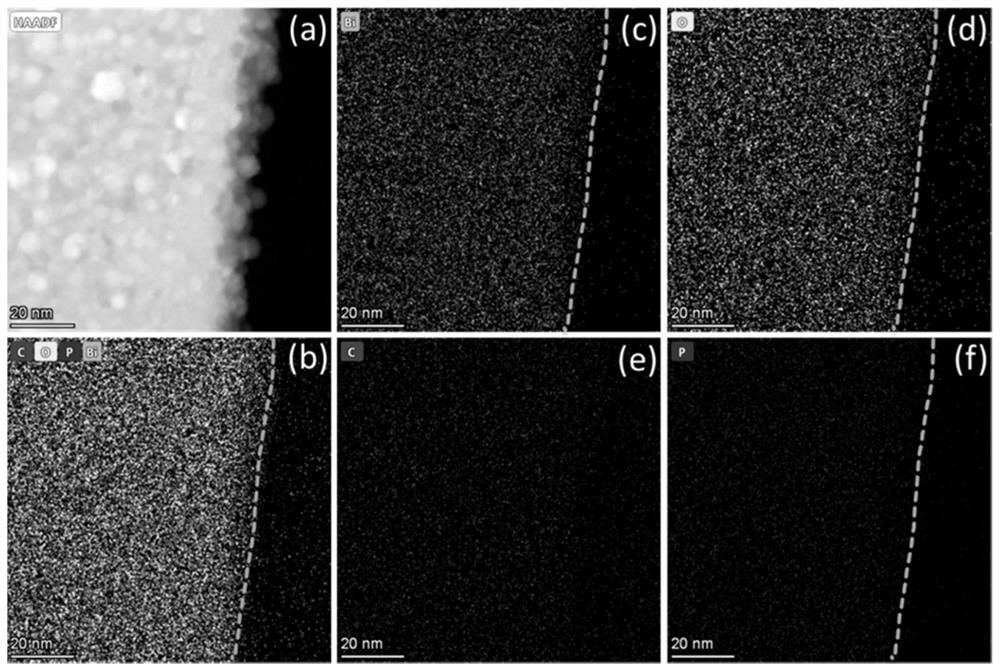

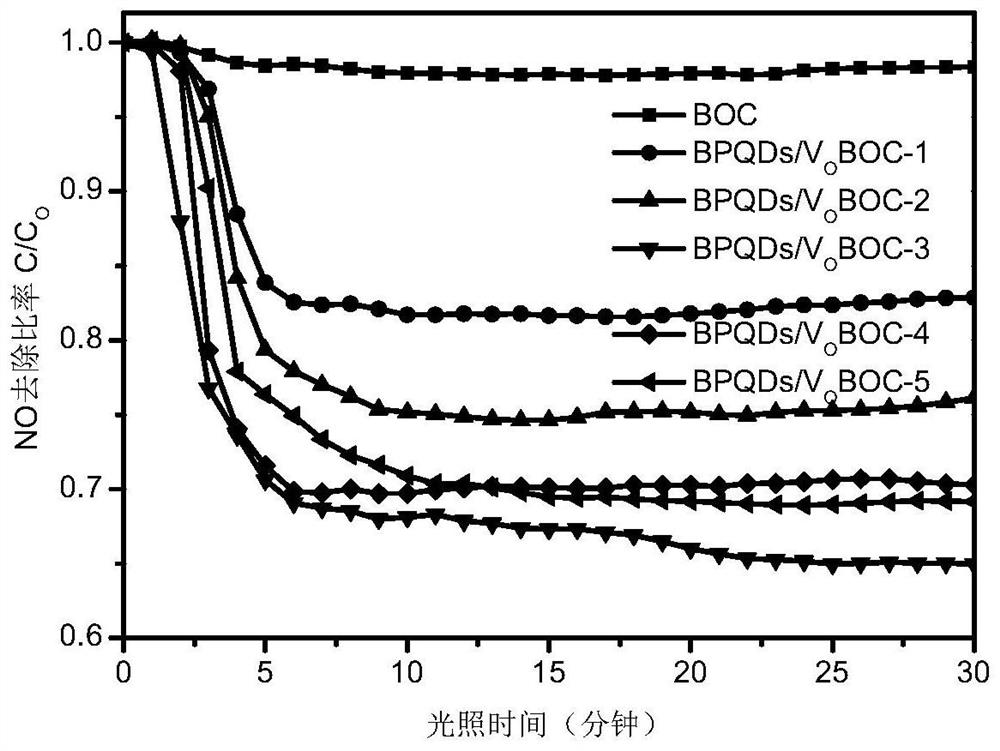

[0030] Weigh 20 mg of black phosphorus and 10 mg of sodium hydroxide in a glove box, add 20 mL of deoxygenated absolute ethanol, seal them in an agate cup, and grind them with a ball mill at 300 rpm for 3 h. Then it was transferred to a round-bottomed flask, 30 mL of deoxygenated absolute ethanol was added, and the solvent was heated to reflux at 80°C for 4 h under nitrogen bubbling, and cooled to room temperature naturally to obtain a black phosphorus quantum dot solution.

[0031] 0.5 g of nano-flaky bismuth oxycarbonate was treated at 280 °C for 3 h at a flow rate of 30 mL / min in a nitrogen atmosphere, then dispersed in an ethanol solution, and 50 μL of black phosphorus quantum dot solution was added. After ultrasonic treatment for 10 min, it was added to a microwave reaction tube. , under the action of power 500W, microwave solvothermal reaction at 60°C for 30min, washed with deionized water and ethanol respectively after natural cooling, and dried at 60°C under vacuum to o...

Embodiment 2

[0033] Weigh 20 mg of black phosphorus and 0.1 g of sodium hydroxide in a glove box, add 20 mL of deoxygenated absolute ethanol, seal them in an agate cup, and grind them with a ball mill at 400 rpm for 6 h. Then it was transferred to a round-bottomed flask, 30 mL of deoxygenated absolute ethanol was added, and the solvent was heated to reflux at 100 °C for 10 h under nitrogen bubbling, and cooled to room temperature naturally to obtain a black phosphorus quantum dot solution.

[0034]0.5 g of nano-flaky bismuth oxycarbonate was treated at 290 °C for 5 h at a flow rate of 40 mL / min in a nitrogen atmosphere, then dispersed in an ethanol solution, and 100 μL of black phosphorus quantum dot solution was added. After ultrasonic treatment for 20 min, it was added to a microwave reaction tube. , under the action of power 700W, microwave solvothermal reaction at 70°C for 10min, washed with deionized water and ethanol respectively after natural cooling, and dried at 60°C under vacuum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com