Method for synergistically treating antibiotic production wastewater

A technology for production wastewater and collaborative treatment, applied in natural water treatment, anaerobic digestion treatment, water treatment parameter control, etc., can solve the problems of small impact of anaerobic biological treatment, loss of treatment capacity, and high processing load of anaerobic biological treatment, To avoid the generation of resistance genes, reduce the content of suspended solids, and achieve the effect of enhanced removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

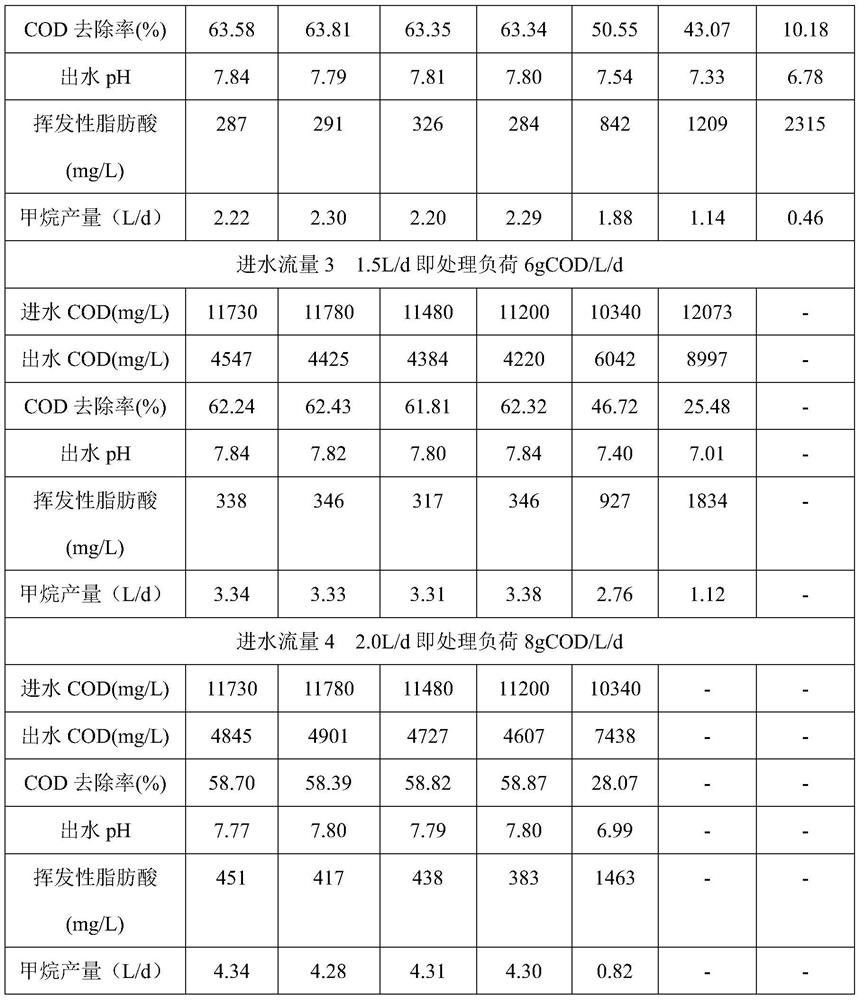

[0092] Example 1: Enhanced Hydrolysis-Coagulation-Ebullating Bed-UASB Technology Treatment of Fermented Oxytetracycline Production Waste Mother Liquor

[0093] 1. Enhanced hydrolysis

[0094] 1-1. Under stirring, add concentrated sodium hydroxide solution to the waste mother liquor produced by oxytetracycline, and adjust the pH of the waste mother liquor to 6 (usually the pH is 5 to 7, preferably 6);

[0095] 1-2. Pass the waste mother liquor after pH adjustment into the heat exchanger, and preheat the waste mother liquor, so that the temperature of the waste mother liquor will rise and reach 60°C (usually 40-60°C); then pass it into high pressure Heat steam to heat the waste mother liquor until the temperature of the waste mother liquor rises and remains at 110°C (usually 85-160°C), and the waste mother liquor is subjected to enhanced hydrolysis treatment at a temperature of 110°C (usually 85-160°C). Among them, the intensive hydrolysis treatment time is 1h (usually 0.5-6h);...

Embodiment 1A

[0138]Example 1A: Enhanced Hydrolysis-Coagulation-Ebullating Bed-UASB Technology Treatment of Fermented Oxytetracycline Production Waste Mother Liquor

[0139] 1. Enhanced hydrolysis

[0140] Same as Step 1 of Example 1.

[0141] 2. Coagulation treatment

[0142] Except that the dosing amount of polyferric chloride is different, the ratio of the mass of suspended matter in every 1L of wastewater to the mass of Fe in the added coagulant iron salt is 1:0.3, the rest are the same as step 2 of Example 1 .

[0143] After the coagulation treatment, the water quality of the coagulation wastewater was measured, and the results are shown in Table 1.

[0144] 3. Fluidized bed separation treatment

[0145] Same as step 3 of Example 1, the concentration of suspended solids in the fluidized bed treated wastewater is 212mg / L, which can be directly used as the influent of UASB; the COD of the wastewater treated by the fluidized bed decreases slightly, being 11780mg / L (usually 11000~1210...

Embodiment 1B

[0149] Example 1B: Enhanced Hydrolysis-Coagulation-Ebullating Bed-UASB Technology Treatment of Fermented Oxytetracycline Production Waste Mother Liquor

[0150] 1. Enhanced hydrolysis

[0151] Same as Step 1 of Example 1.

[0152] 2. Coagulation treatment

[0153] Except that the dosage of polyferric chloride is different, the ratio of the concentration of suspended solids per 1L of wastewater to the mass of Fe in the added iron salt is 1:0.5, and the rest are the same as step 2 of Example 1.

[0154] After the coagulation treatment, the water quality of the coagulation wastewater was measured, and the results are shown in Table 1.

[0155] 3. Fluidized bed separation treatment

[0156] Same as step 3 of Example 1, the concentration of suspended solids in the fluidized bed treated wastewater is 198mg / L, which can be directly used as the influent of UASB; the COD of the wastewater treated by the fluidized bed decreases slightly, being 11480mg / L (usually 11000~12100mg / L); al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Alkalinity | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com