Pure culture method of anaerobic microorganisms

An anaerobic microorganism, pure culture technology, applied in the field of bioengineering, can solve the problems of culture waste liquid pollution, high solubility, excessive reducing dose, etc., to achieve the effect of simplified separation, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

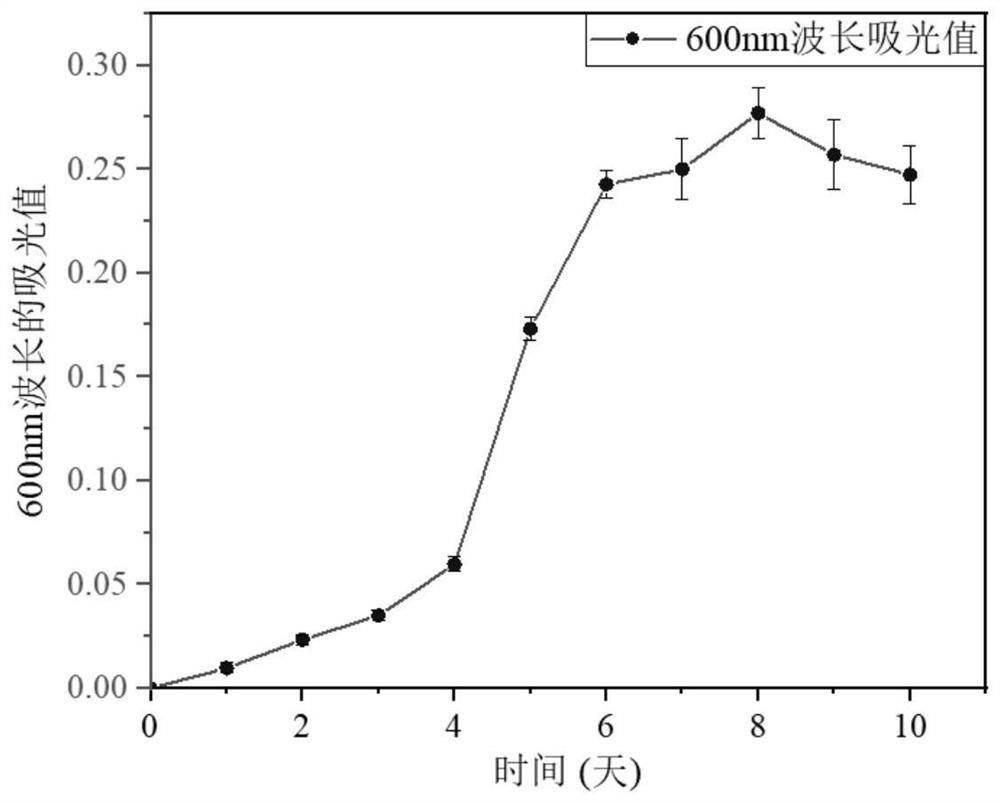

[0029] Implementation 1: Taking the cultivation of Geobacter sulfur-reducing as an example

[0030] Liquid culture solution composition: the following components are included in each liter of liquid culture solution: 1.5g NH 4 Cl, 0.6gNa 2 HPO 4 , 0.1g KCl, 0.82g CH 3 COONa, 2.5g NaHCO 3 , 8.0g disodium fumarate, 10mL trace element stock solution; 10mL vitamin solution; the following components are included in each liter of trace element stock solution: 1.5g nitrilotriacetic acid, 3.0g MgSO 4 ·7H 2 O, 0.5gMnSO 4 ·H 2 O, 1.0g NaCl, 0.1g FeSO 4 ·7H 2 O, 0.1g CoCl 2 ·6H 2 O, 0.76g CaCl 2 , 0.1gZnSO 4 ·7H 2 O, 0.01g CuSO 4 ·5H 2 O, 0.02g KAl(SO 4 ) 2 ·12H 2O, 0.01g H 3 BO 3 , 0.01g Na 2 MoO 4 ·12H 2 O; each liter of vitamin liquid includes the following components: 2mg biotin, 2mg folic acid, 10mg vitamin B 6 Hydrochloride, Thiamine Hydrochloride 5mg, Riboflavin 5mg, Vitamin B 5mg 3 , 5mg D-calcium pantothenate, 0.1mg vitamin B 12 , 5mg p-aminobenzoic aci...

Embodiment 2~6

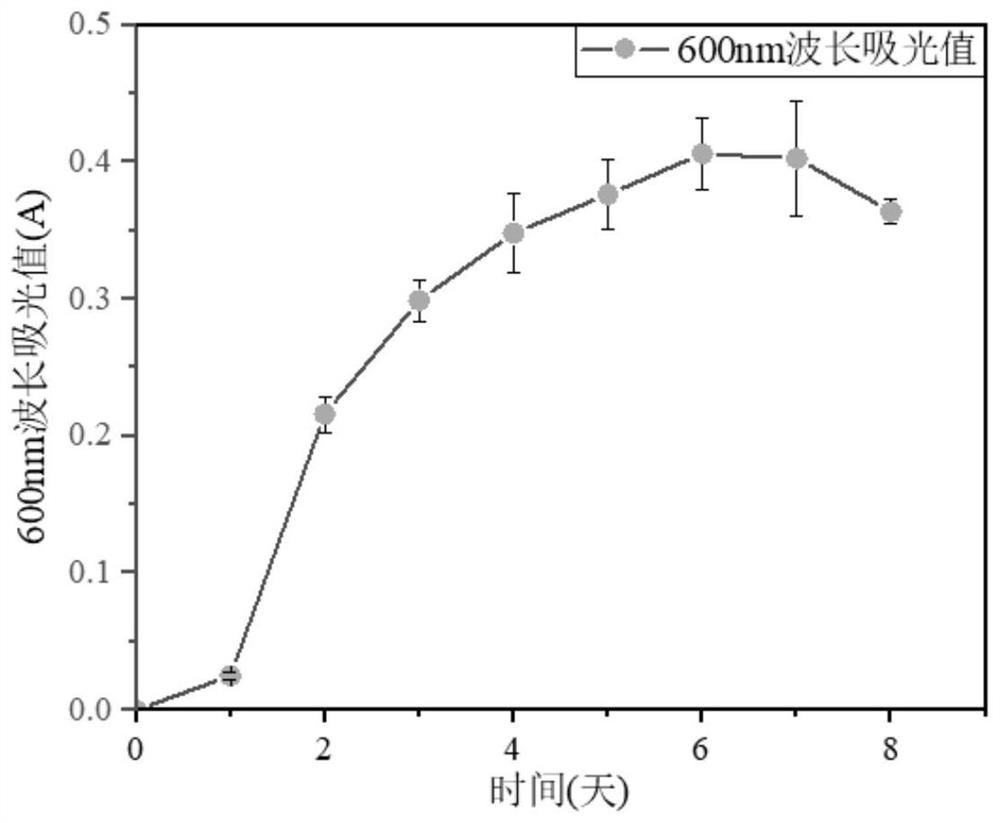

[0034] Examples 2 to 6: all take the cultivation of P. Acetatigenes as an example.

[0035] The components of the liquid culture solution are: each liter of the liquid culture solution includes the following components: 5g polypeptone, 5g tryptone, 10g yeast extract, 10g glucose, 0.96L distilled water, and 40mL salt solution; the salt solution per liter Contains the following ingredients: 0.2g CaCl 2 , 0.4g MgSO 4 ·7H 2 O, 1.0g K 2 HPO 4 , 1.0g KH 2 PO 4 , 10.0g NaHCO 3 , 2.0g NaCl, 1L distilled water.

Embodiment 2

[0037] Step 1: prepare a liquid culture solution, heat it in a water bath, add dropwise 1 mol / L NaOH to adjust pH=7.2; boil, dropwise add resazurin to a concentration of 0.1 mg / L, and dispense into a thin tube to obtain a culture tube; step 2: Insert the aeration needle into the culture tube with a mass ratio of 80% N 2 / 20%H 2 The mixed gas is aerated for 20 minutes, and the rubber stopper is quickly closed;

[0038] Step 3: Place the culture tube in an autoclave, sterilize it at high temperature, set the temperature to 121°C for 20 minutes; transfer it to an ultra-clean bench and cool it to room temperature, put it in a constant temperature incubator for 48 hours, and sterilize it with UV light 25 minutes.

[0039] Step 4: Use a syringe to inject 3% anaerobic microorganism seed liquid into the culture tube, and put it into a 37°C constant temperature incubator for 6 days to obtain anaerobic microorganisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com