Vertical kiln lining for roasting positive electrode material of lithium battery and preparation method of vertical kiln lining

A cathode material and a lithium battery technology, which is applied in the field of a shaft kiln lining for roasting a cathode material of a lithium battery and its preparation field, can solve the problems of difficulty in recycling, the corrosion resistance of the saggar cannot be effectively guaranteed, the battery performance is deteriorated, and the like. Avoid physical/chemical reactions, solve battery performance degradation, and increase the effect of crystal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

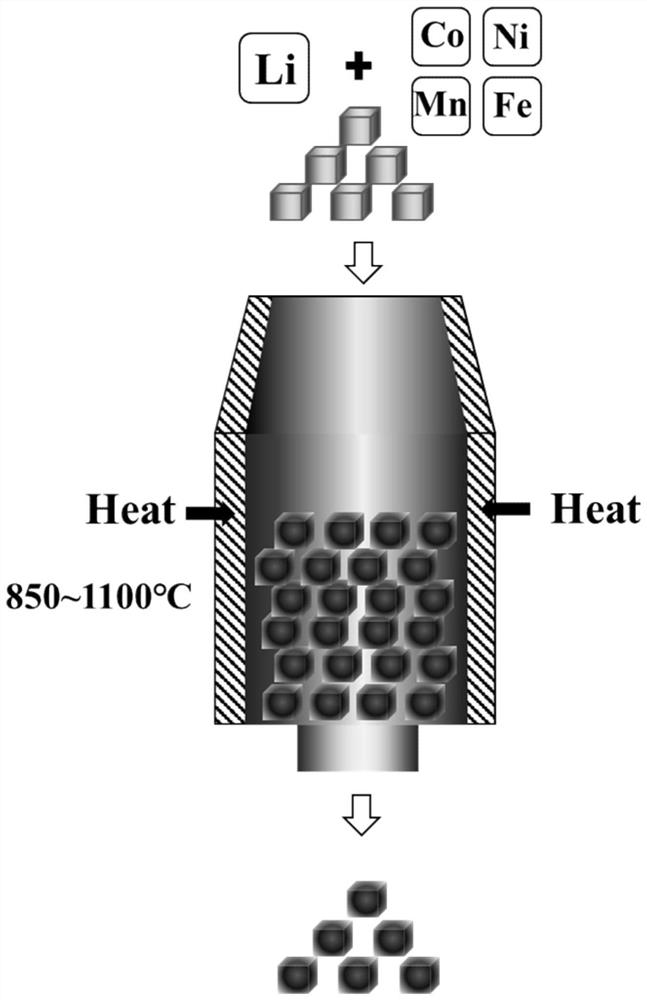

Method used

Image

Examples

Embodiment 1

[0031] A shaft kiln lining for firing lithium battery cathode materials and a preparation method thereof. The preparation method described in this embodiment:

[0032] Mix 52.0wt% cordierite, 43.0wt% mullite, 1.5wt% kaleidite, 2.3wt% cerium oxide and 1.2wt% binding agent to obtain a mixture; Molded and kept at 150°C for 6 hours to prepare the shaft kiln lining for firing lithium battery cathode materials.

[0033] The binding agent is zirconium phosphate.

[0034] The forming is pressure forming.

Embodiment 2

[0036] A shaft kiln lining for firing lithium battery cathode materials and a preparation method thereof. The preparation method described in this embodiment:

[0037]Mix 56wt% of cordierite, 39wt% of mullite, 4.5wt% of kaleidite, 0.3wt% of cerium oxide and 0.2wt% of binder to obtain a mixture; then shape the mixture, Insulated at 160°C for 5 hours to prepare a shaft kiln lining for firing lithium battery anode materials.

[0038] The binding agent is aluminum dihydrogen phosphate.

[0039] The molding is casting molding.

Embodiment 3

[0041] A shaft kiln lining for firing lithium battery cathode materials and a preparation method thereof. The preparation method described in this embodiment:

[0042] Mix 58wt% cordierite, 34wt% mullite, 2.7wt% kaleidite, 3.3wt% cerium oxide and 2.0wt% binder to obtain a mixture; then shape the mixture, Insulate at 170°C for 4 hours to prepare a shaft kiln lining for firing lithium battery anode materials.

[0043] The binding agent is aluminum dihydrogen phosphate.

[0044] The molding is smear molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com