Protease refining and drying method

A drying method and protease technology, which is applied in the field of protease refining and drying, can solve the problems that affect the efficiency, cost and product quality of vacuum freeze-drying of materials, freeze-dried materials are easily contaminated by microorganisms, and the temperature of the interlayer plate is uneven, etc., to achieve High stability of enzyme activity, simple method and smooth slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

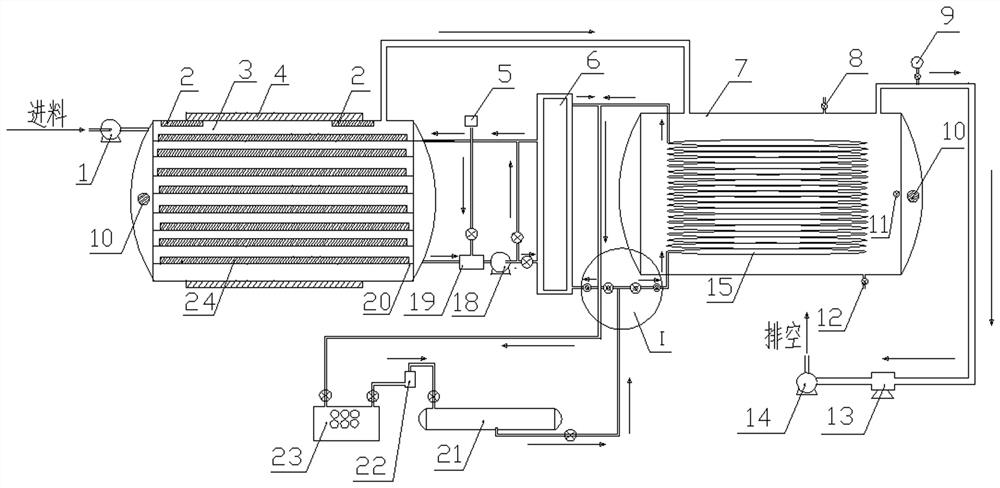

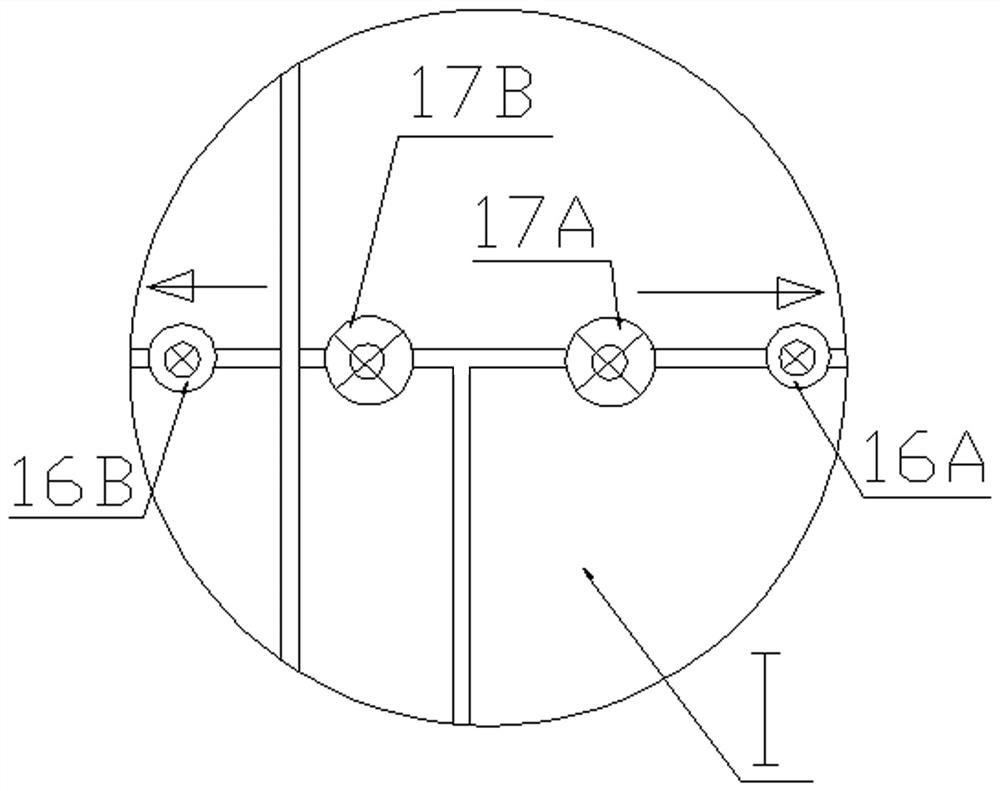

Method used

Image

Examples

Embodiment 1

[0052] A method for refining and drying bacillus subtilisin, comprising the following steps:

[0053] (1) At room temperature, add the crude subtilisin raw material purchased from outside and water into the extraction tank, then completely dissolve sodium chloride in water to make a solution, add it to the extraction tank, stir and extract for 95 minutes, The extraction temperature was controlled between 19.5 and 22.5°C, and it was left to stand for 40 minutes after the end; wherein, after the feeding was completed, the weight ratio of protease raw material and water in the mixed solution was 1:17, and the mass percentage of sodium chloride was 1%.

[0054](2) Add flocculant Ⅰ to the extraction standing liquid obtained in step (1). The flocculant Ⅰ includes sodium chloride and calcium chloride, and the addition amount (mass percentage) of sodium chloride and calcium chloride is 1.0 %, 0.8%. Dissolve sodium chloride and calcium chloride in water respectively to make a solution...

Embodiment 2

[0063] A method for refining and drying bacillus subtilisin, comprising the following steps:

[0064] (1) At room temperature, add the crude subtilisin raw material purchased from outside and water into the extraction tank, then completely dissolve sodium sulfate in water to make a solution, add it to the extraction tank, stir and extract for 95 minutes, and extract The temperature was controlled between 19.5 and 22°C, and it was left to stand for 40 minutes after the extraction was completed; wherein, after the addition was completed, the weight ratio of protease raw material and water in the mixed solution was 1:17, and the mass percentage of sodium sulfate was 1%.

[0065] (2) Add flocculant I to the extracting standing liquid obtained in step (1). The flocculant I includes sodium sulfate and calcium sulfate, and the addition amounts of sodium sulfate and calcium sulfate are 1.0% and 0.8% respectively. Dissolve sodium sulfate and calcium sulfate in water respectively to mak...

Embodiment 3

[0074] A method for refining and drying bacillus licheniformis protease, comprising the following steps:

[0075] (1) At room temperature, add the crude Bacillus licheniformis protease raw material purchased from outside and water into the extraction tank, then completely dissolve sodium sulfate in water to make a solution, add it to the extraction tank, stir and extract for 80 minutes, and extract The temperature is controlled between 21 and 22°C, and it is left to stand for 40 minutes after the extraction is completed; wherein, after the feeding is completed, the weight ratio of protease raw material and water in the mixed solution is 1:20, and the mass percentage of sodium sulfate is 1.1%.

[0076] (2) Add flocculant Ⅰ to the extraction standing liquid obtained in step (1). The flocculant Ⅰ includes sodium sulfate and calcium sulfate, and the addition amount (mass percentage) of sodium sulfate and calcium sulfate is 1.1% and 0.9% respectively . Dissolve sodium sulfate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com