Ganoderma lucidum spore powder wall breaking technology

A technology of ganoderma spore powder and broken ganoderma spore powder, which is applied in the field of ganoderma spore powder breaking process, can solve the problems of loss of active ingredients, pollution, and insufficient wall breaking rate, so as to improve the purity and content of active ingredients and enhance anti-oxidation Sexuality, strong antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

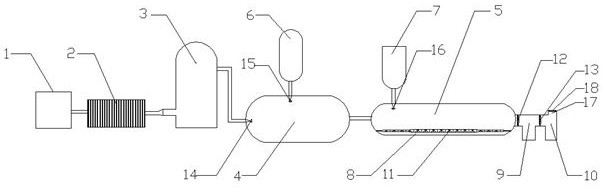

Image

Examples

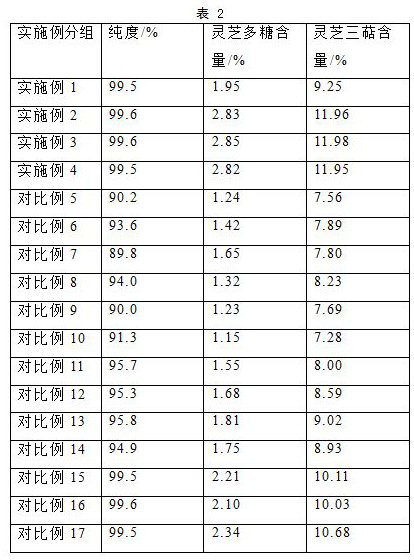

Embodiment 1

[0039]This example provides a Ganoderma lucidum spore powder, including the following steps:

[0040] S1, Take Ganoderma Ganoderma spore dry products, pulverized into 1 μm Ganoderma spore powder in the ultrafine pulverizer, then placed in a sealed container, at normal temperature, flowing into the water vapor moisturizing 20 min, followed by standing at -15 ° C for 5 h After the ultrafine pulverizer is placed into 1 μm powder;

[0041] S2, the material obtained by step S1 is placed in a gas flow pulverizer, and then a 1 degree of 2 μm ceramic powder is added, and the gas stream is pulverized under 2 ° C for 2 h, resulting in a mixture of broken Ganoderma lucidum spore powder;

[0042] S3, the broken ganoderma ganoderma spore powder mixture obtained by step S2 is separated into the separation device, collecting the wrapping ganoderma spore powder, a spore wall mixture, respectively;

[0043] S4, after drying the collected broken ganoderma lucidum spore powder, it is to be broken in...

Embodiment 2

[0053] On the basis of Example 1, the present embodiment also provides a Ganoderma Ganoderma Ganoderma Ganoderma Ganoderma Ganoderma Ganoderma Filter, which includes a filter backbone and an antioxidant filler, including a mass ratio of 1: 1. : 1.2: 0.3 Spore wall mixture, citric acid, natural ve, flower jacket. The preparation method of the antioxidant filler includes the steps of:

[0054] A. Take the spore wall mixture obtained by step S3, washed in an ultrasonic cleaning machine for 2 h, and then dried after filtration, and the sieves were separated.

[0055] B. Take citric acid and natural Ve, then placed in a high-speed mixer, then the sieve obtained by step A is added, stirred at 60 ° C, 1500R / min.

[0056] C, take a flower clothes, after washing, put into 200 kW ultrafine pulverizer, pulverized into a 3 μm peanut powder, then add the material obtained by step b, and stir well and uniform.

Embodiment 3

[0058] This example provides a Ganoderma lucidum spore powder, including the following steps:

[0059] S1, Pinnose spore dry product, pulverized into 1.5 μm Ganoderma spore powder in the ultrafine pulverizer, and then put it in a closed container, and the saturated water vapor is concentrated at normal temperature, then in -18 ° C. After 5.5 h, the ultrafine pulverizer was placed into 1.2 μm powder;

[0060] S2, the material obtained by step S1 is placed in a gas flow pulverizer, and then 2 times of 2.2 μm ceramic powder is added, and the gas stream is pulverized at 3 ° C for 3 h, resulting in a mixture of broken Ganoderma lucidum spore powder;

[0061] S3, the broken ganoderma ganoderma spore powder mixture obtained by step S2 is separated into the separation device, collecting the wrapping ganoderma spore powder, a spore wall mixture, respectively;

[0062] S4, the collected broken Ganoderma lucidum spore powder is dried to break the green ganoderma spore powder.

[0063] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com