Combined inhibitor for separation of copper sulfide ore containing kaolin and separation method

A technology combining inhibitors and separation methods, which is applied in the field of mineral metallurgical processing, can solve the problems of large amount of beneficiation agents, difficulty in copper-sulfur separation, and low recovery rate of gold and silver, so as to improve the copper-sulfur separation effect, improve the separation effect, and The effect of technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

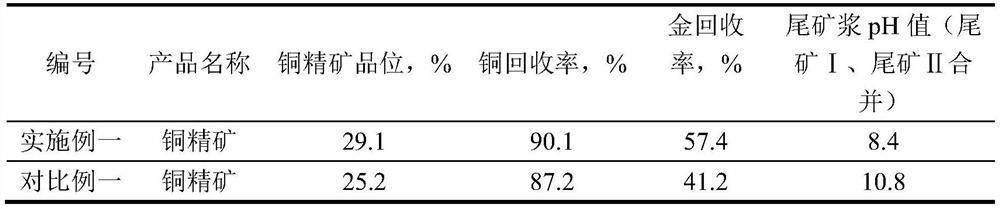

Embodiment 1

[0076] The raw ore grades are Cu 0.65% and S 5.19%. The mineral composition of this ore is relatively complex. The metallic minerals include chalcocite, copper blue, chalcopyrite, pyrite, pyrrhotite, and limonite. The gangue minerals are mainly quartz, kaolin, mica, potassium feldspar, chlorite, etc., of which the mass percentage of kaolin is 8.2%. The copper mineral inlay is relatively complex, and it is mostly associated with pyrite and hydrokaolinite.

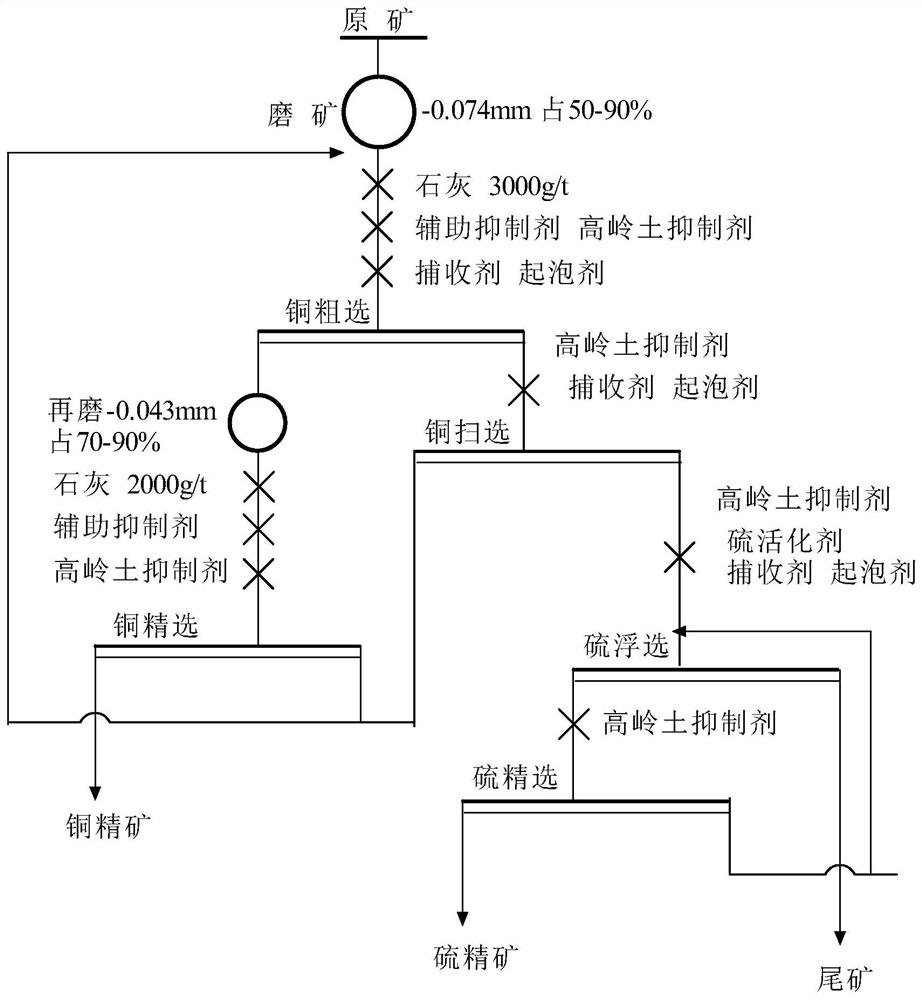

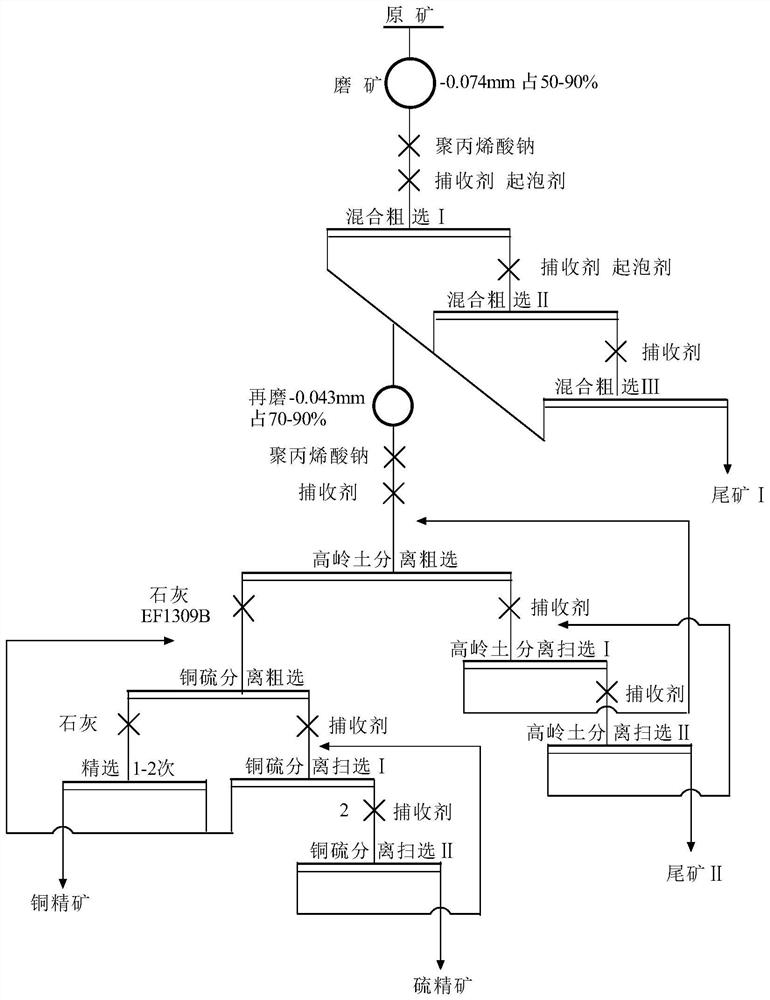

[0077] The specific steps of the process flow are:

[0078] 1) Crushing and grinding the raw ore to fully dissociate the useful minerals and gangue minerals in the copper-sulfur ore, grind the ore to a particle size of -0.074mm, accounting for 65% of the copper-sulfur ore, and add water to adjust the slurry until the mass concentration of the ore pulp is 33 %, the pH of the pulp is 8.3;

[0079] 2) Add inhibitor sodium polyacrylate 30g / t (that is, add 30g sodium polyacrylate per ton of pulp), collector ethyl xanthate 30g / t...

Embodiment 2

[0093] The raw ore grades are Cu 0.85% and S 12.2%. The mineral composition of the ore is relatively complex, and the metallic minerals include chalcopyrite, chalcocite, bornite, pyrrhotite, pyrite, marcasite and so on. The gangue minerals are mainly quartz, kaolin and garnet, of which the mass percentage of kaolin is 10.6%.

[0094] The specific steps of the process flow are:

[0095] 1) Crushing and grinding the raw ore to fully dissociate the useful minerals and gangue minerals in the copper-sulfur ore, grind the ore to a particle size of -0.074mm, accounting for 70% of the copper-sulfur ore, and add water to adjust the slurry until the mass concentration of the ore pulp is 33 %, the pH of the pulp is 8.1;

[0096] 2) Add inhibitor sodium polyacrylate 50g / t, collector ethyl xanthate 35g / t to the pulp after grinding in step 1), stir for 3min, add foaming agent methyl isobutyl methanol 25g / t, Stir for 2 minutes, carry out the first copper-sulfur mixed roughing, and the rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com