High-purity aluminum oxide ceramic substrate and preparation process thereof

A high-purity alumina and ceramic substrate technology, applied in the field of high-purity alumina ceramic substrate and its preparation process, can solve the problems of volume resistivity and thermal conductivity are not very good, and achieve the effect of easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

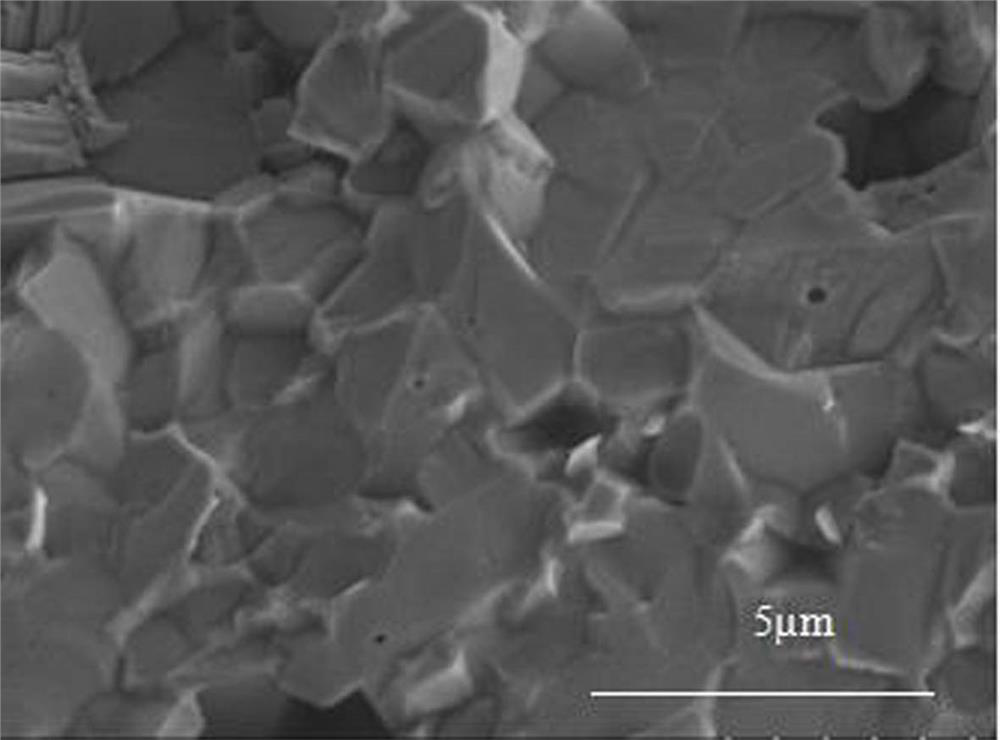

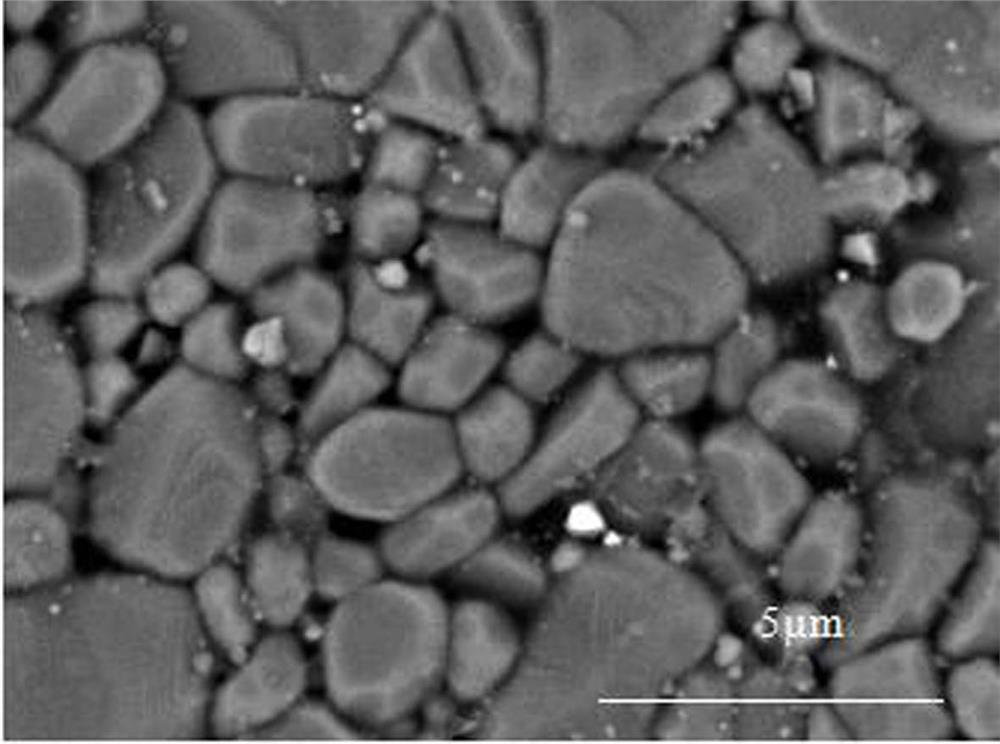

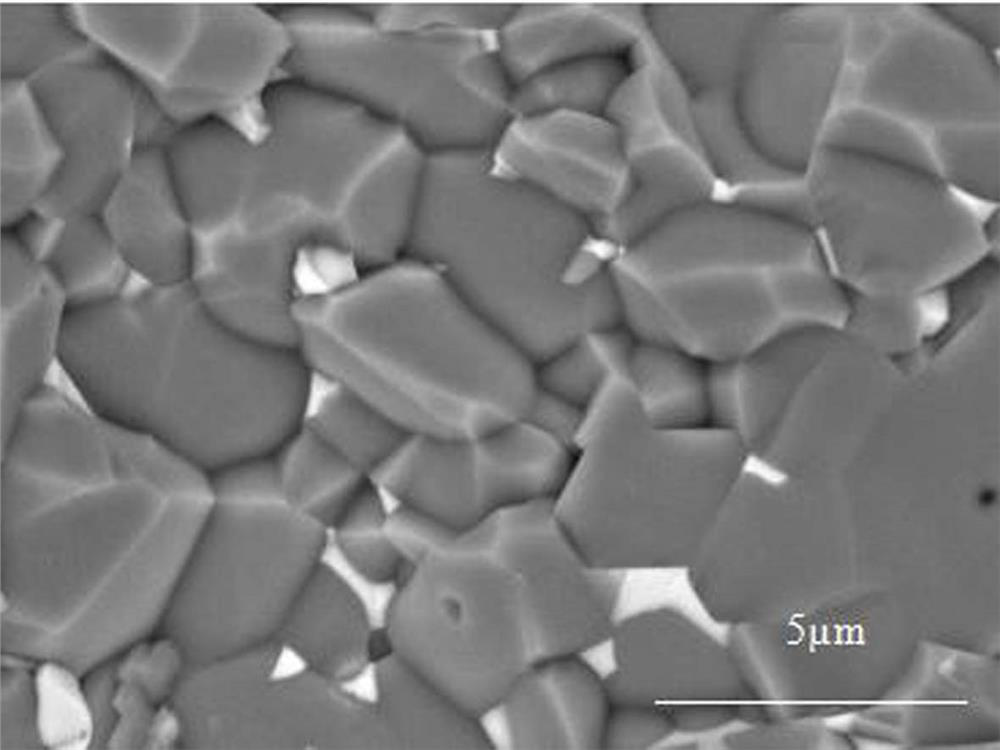

Image

Examples

preparation example Construction

[0028] The preparation process of the above-mentioned high-purity alumina ceramic substrate is as follows:

[0029] Add the formula amount of α-alumina powder, magnesium aluminum spinel powder, dispersant and solvent into the ball mill in proportion, and disperse by ball milling for 24-48 hours; then add adhesive and plasticizer for secondary ball milling for 20-24 hours;

[0030] The material is discharged from the ball mill, and the cast slurry with a viscosity of 20000-30000mPa·s is obtained by vacuum defoaming; the cast slurry is cast on a cast machine, and the obtained cast green sheet is cut into corresponding the size and shape of

[0031] It is sintered in a high-temperature kiln, the temperature of the sintering temperature zone in the high-temperature kiln is 1580°C-1620°C, and the high-temperature insulation is kept for 3-5 hours to obtain a high-purity alumina ceramic substrate.

[0032] First, add the α-alumina powder, magnesium aluminum spinel powder, dispersant...

Embodiment 1

[0035] A high-purity alumina ceramic substrate and its preparation process are prepared from the following raw materials in parts by weight: 99% of the total weight of inorganic powder D 50 The α-alumina powder with a particle size of 1.5 μm is the main phase material, and the total weight of the inorganic powder is 0.7% D 50 Magnesium aluminum spinel powder with a particle size of 0.9 μm, and 0.15% of the total weight of the inorganic powder 50 Lanthanum oxide with a particle size of 0.8 μm and 0.15% of the total weight of inorganic powder D 50 Yttrium oxide with a particle size of 0.8 μm is used as a special additive, and the four together form an inorganic powder. And add solvent 28% (addition is 28% of inorganic powder gross weight), dispersant 0.5% (addition is 0.8% of inorganic powder gross weight), ball mill disperses 24 hours; Add binding agent 7% ( The addition amount is 7% of the total weight of the inorganic powder) and 3% of the plasticizer (the addition is 3% of...

Embodiment 2

[0037] A high-purity alumina ceramic substrate and its preparation process are prepared from the following raw materials in parts by weight: D 50 The α-alumina powder with a particle size of 0.8 μm is the main phase material, and the total weight of the inorganic powder is 0.4% D50 Magnesium aluminum spinel powder with a particle size of 0.5 μm, and 0.05% of the total weight of the inorganic powder 50 Lanthanum oxide with a particle size of 0.5 μm and 0.05% of the total weight of inorganic powder D 50 The yttrium oxide with a particle diameter of 0.5 μm is used as a special additive to form an inorganic powder, and 28% of a solvent (the addition is 28% of the total weight of the inorganic powder) and 1.6% of a dispersant (the addition is 28% of the total weight of the inorganic powder) are added. 1.6%), ball milling and dispersing for 48 hours; add 9% of binding agent (the addition is 9% of the total weight of the inorganic powder) and 4% of plasticizer (the addition is 4% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com