Method for recovering choline chloride and tartrate from choline bitartrate waste mother liquor

A technology of choline bitartrate and dicholine bitartrate, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve problems such as difficult recovery of choline bitartrate mother liquor, and achieve economical The benefits are considerable, the risk of environmental pollution is reduced, and the effect of eliminating waste liquid storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

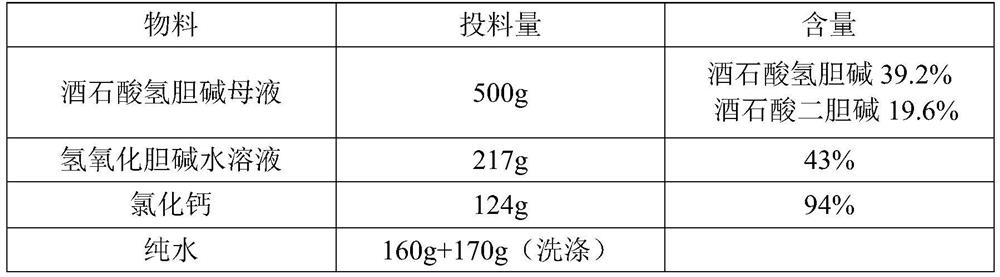

[0024] Reclaim choline chloride and calcium tartrate salt small test in embodiment 1 choline hydrogen bitartrate waste mother liquor

[0025] Table 1 Feeding ratio

[0026]

[0027] (1) Weigh 500 g of choline bitartrate waste mother liquor, the content of choline bitartrate in the mother liquor is 39.2%, and the content of dicholine bitartrate is 19.6%, pour it into a 1000ml glass reaction bottle, start stirring and heat up to 30°C for later use.

[0028] (2) take by weighing choline hydroxide aqueous solution 217g, choline hydroxide content 43%, slowly pour in the glass reaction bottle that fills choline hydrogen bitartrate waste mother liquor and carry out neutralization reaction, generate dihydrocholine bitartrate, stir After 30 minutes, measure pH8.3 for later use.

[0029] (3) Take by weighing 160g of pure water and place it in a 500ml beaker for subsequent use, take by weighing 124g of calcium chloride with a content of 94% and place it in a 500ml beaker filled with ...

Embodiment 2

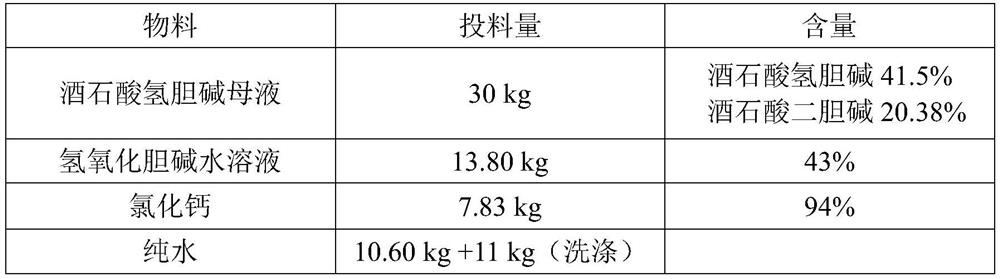

[0033] Embodiment 2: Pilot test of reclaiming choline chloride and calcium tartrate in choline bitartrate waste mother liquor

[0034] Table 2 Feeding ratio

[0035]

[0036] (1) Take by weighing 30 kg of choline bitartrate waste mother liquor, in the mother liquor, the content of choline bitartrate is 41.5%, and the content of dicholine bitartrate is 20.38%, vacuumize it to a glass-lined reactor, start stirring and heat up to 30° C. for subsequent use;

[0037] (2) Take by weighing 13.80kg of choline hydroxide aqueous solution, 43% of choline hydroxide content, vacuum pump to fill in the glass-lined reactor of choline hydrogen bitartrate waste mother liquor, carry out neutralization reaction and generate dicholine bitartrate, neutralize The reaction is exothermic, the feed rate is controlled, stirred for 30 minutes, and the pH is measured to be 8.5 for later use;

[0038] (3) 10.60 kg of pure water was weighed and placed in a dissolving tank for subsequent use, and 7.83 k...

Embodiment 3

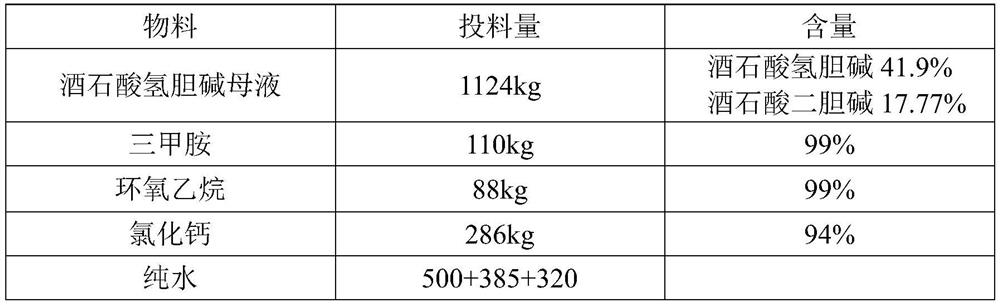

[0042] Trial production of reclaiming choline chloride and calcium salt of tartrate in embodiment 3 choline hydrogen bitartrate waste mother liquor

[0043] Feeding ratio

[0044]

[0045] (1) Take by weighing choline bitartrate waste mother liquor 1124kg, mother liquor pH value 3.8, add water 500Kg to dilute, open and stir for subsequent use;

[0046] (2) Open the trimethylamine feed valve, the initial temperature is 22°C, control the flow rate ≤ 65Kg / h, control the pressure in the kettle ≤ 0.1MPa, close the trimethylamine feed valve after feeding 110Kg of trimethylamine, measure the pH value to 7.6, and continue stirring Reacted for 30 minutes, and the end temperature was 29°C to obtain amine bitartrate;

[0047] (3) Open the ethylene oxide feed valve, the initial temperature is 29 ° C, the control flow is ≤ 30Kg / h, the pressure in the control kettle is ≤ 0.1MPa, and the ethylene oxide feed valve is closed after 88Kg of ethylene oxide is passed. The measured pH value was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com