Efficient gallium oxide doping method based on unbalanced laser plasma

A laser plasma and plasma technology, which is applied to the field of high-efficiency doping of gallium oxide in plasma, can solve the problems of low doping activation efficiency and high temperature, and achieve the improvement of growth quality, fast growth speed and free carrier concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Since gallium oxide materials have a much larger band gap than semiconductor materials such as silicon, germanium, and gallium nitride, it is difficult to achieve high-efficiency activation after doping through existing process methods. Therefore, this embodiment provides a method based on unbalanced The gallium oxide high-efficiency doping method of laser plasma, the method of this embodiment, adopts the pulsed laser deposition process (PLD), grows the doped gallium oxide epitaxial layer on the gallium oxide substrate, so that the growth rate of the doped gallium oxide epitaxial layer It is faster, and the laser is used to bombard the doped gallium oxide target to obtain the doped gallium oxide plasma. The plasma has its own energy (kinetic energy and thermal energy), which is easy to activate the doping.

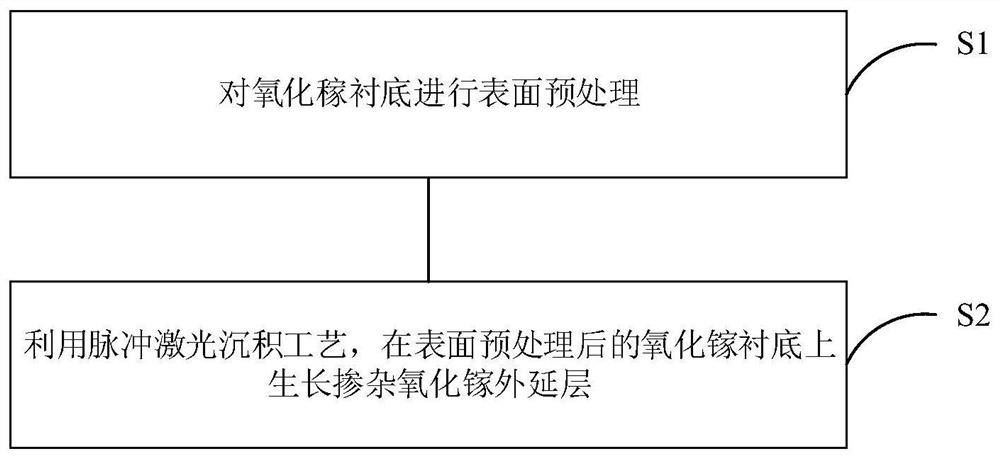

[0029] See figure 1 , figure 1 It is a flow chart of an efficient gallium oxide doping method based on non-equilibrium laser plasma provided by an embodiment of th...

Embodiment 2

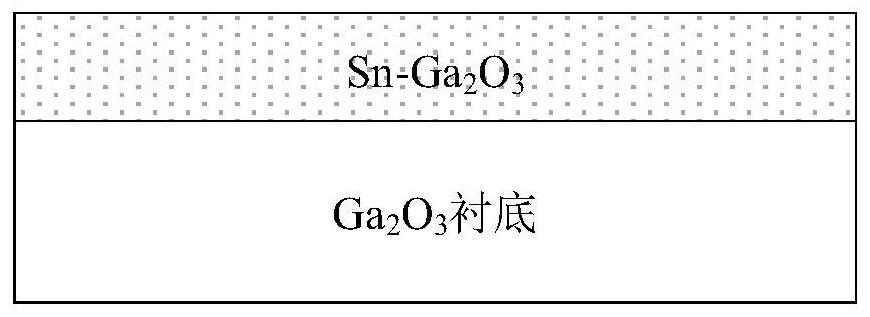

[0049] This embodiment takes the Sn-doped gallium oxide epitaxial layer as an example to describe the method of Embodiment 1 in detail, wherein the Sn doping concentration is 4.89×10 20 cm -3 .

[0050] Specifically, please refer to Figure 2a-Figure 2b , Figure 2a-Figure 2b It is a process flow diagram of an efficient gallium oxide doping method based on non-equilibrium laser plasma provided by an embodiment of the present invention. As shown in the figure, in this embodiment, the method includes the following steps:

[0051] Step 1: Put the gallium oxide substrate into the H with a volume ratio of 3:1 2 SO 4 and H 2 o 2 Etched in the mixed solution (piranha etching solution) for 40s, and then washed three times with deionized water;

[0052] Step 2: Put the etched and cleaned gallium oxide substrate into a muffle furnace for annealing treatment, the annealing temperature is 850°C, the heating rate is 10°C / min, and the annealing time is 10min, to obtain the gallium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com