Flame-retardant fireproof rope net wire and production process thereof

A flame-retardant, rope-net technology, applied in the field of fire-resistant rope nets, can solve the problems of poor flame-retardant and fire-resistant performance of fiber nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment is flame retardant additive, and the preparation process of described flame retardant additive is as follows:

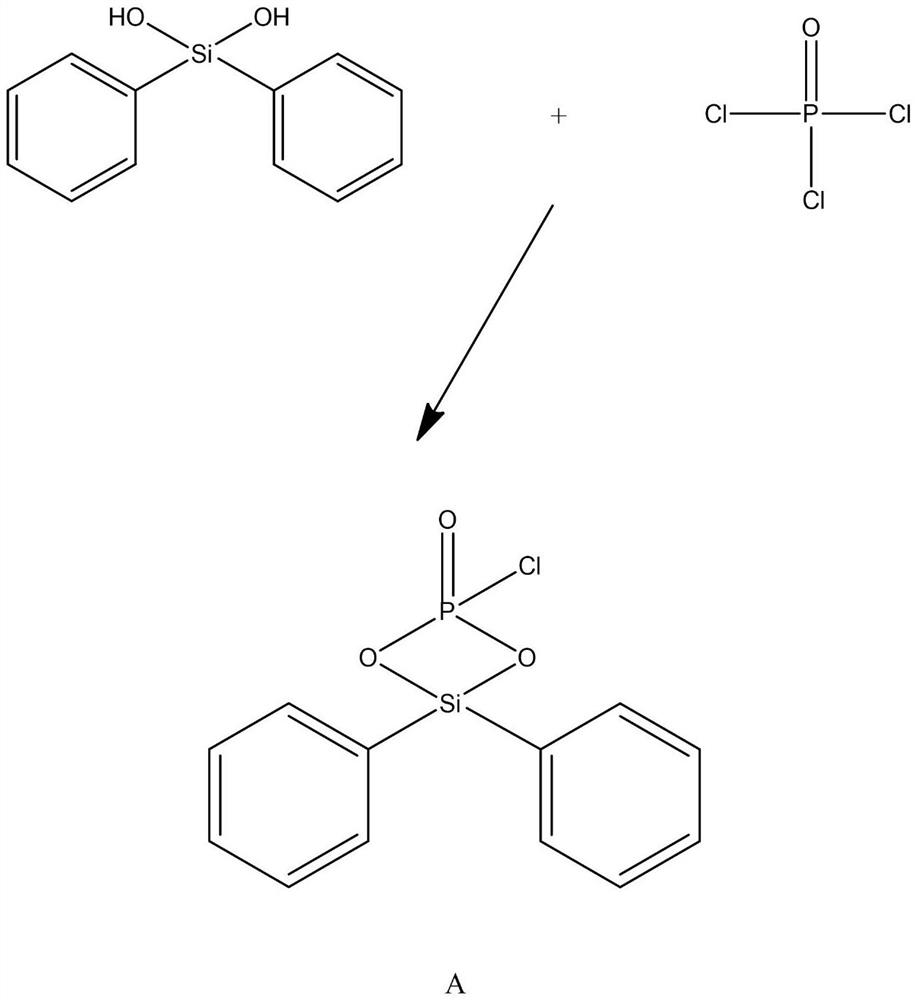

[0037] S1: Add diphenylsilanediol, toluene, and triethylamine to a four-necked flask equipped with a condensing reflux device, a constant pressure dropping funnel, a stirrer, and a thermometer, under the condition of a stirring speed of 300r / min Stir until the solid is completely dissolved to obtain a reaction solution a; control the ratio of diphenylsilanediol, toluene, and triethylamine to 117.14g: 300mL: 82.32g;

[0038] S2: Add phosphorus oxychloride to dry chloroform, and stir until the solid is completely dissolved at a stirring speed of 300r / min to obtain reaction solution b; control the dosage ratio of phosphorus oxychloride and chloroform to 87.50g: 200mL;

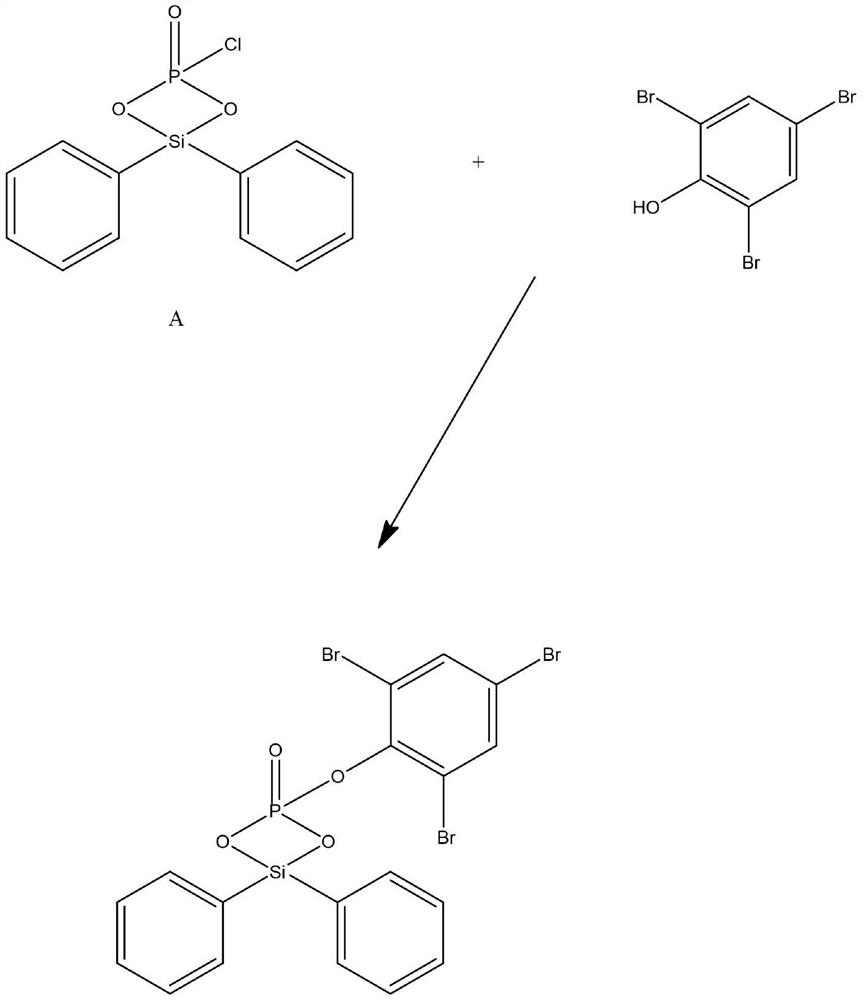

[0039] S3: Add the reaction solution b to the four-necked flask, start stirring and circulate the condensed water, add it dropwise to the reaction solution a under the cond...

Embodiment 2

[0042] The present embodiment is flame retardant additive, and the preparation process of described flame retardant additive is as follows:

[0043] S1: Add diphenylsilanediol, toluene, and triethylamine to a four-necked flask equipped with a condensing reflux device, a constant pressure dropping funnel, a stirrer, and a thermometer, under the condition of a stirring speed of 500r / min Stir until the solid is completely dissolved to obtain a reaction solution a; control the ratio of diphenylsilanediol, toluene, and triethylamine to 117.14g: 300mL: 82.32g;

[0044] S2: Add phosphorus oxychloride to dry chloroform, and stir until the solid is completely dissolved at a stirring speed of 500r / min to obtain a reaction solution b; control the dosage ratio of phosphorus oxychloride and chloroform to 87.50g: 200mL;

[0045] S3: Add the reaction solution b into the four-necked flask, start stirring and circulate the condensed water, add it dropwise to the reaction solution a under the ...

Embodiment 3

[0048] This embodiment is a production process of a flame-retardant fireproof rope mesh line, which includes the following steps:

[0049] Step 1: Weigh 80 parts of high-density polyethylene, 0.1 part of antioxidant, 0.3 part of ultraviolet absorber, 0.1 part of dispersant, 1 part of silane coupling agent, 2 parts of titanium dioxide and the barrier resin from Example 1 according to parts by weight. 2 parts of fuel additives; the antioxidant is antioxidant 168; the ultraviolet absorber is light stabilizer 744; the dispersant is a mixture of paraffin and calcium stearate in a mass ratio of 1:1; The coupling agent is silane coupling agent KH-550;

[0050] Step 2: uniformly mix high-density polyethylene, antioxidant, ultraviolet absorber, dispersant, silane coupling agent, titanium dioxide, and flame retardant additives to obtain a mixture;

[0051] Step 3: adding the mixture into an extruder for extrusion and granulation to obtain flame-retardant plastic particles, and then inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com