A composite hemostatic repair material and its preparation method

A technology of repair materials and composite materials, which is applied in the field of composite hemostatic repair materials and its preparation, can solve problems such as limited hemostatic effect, harsh required conditions, and complicated preparation process, and achieves simple and easy-to-operate preparation methods, strong liquid absorption performance, The effect of promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Wash the natural clam shells with deionized water and crush them, put the shell fragments in a pulverizer for 5 minutes, pass the obtained shell powder through a 200-mesh sieve, and then calcinate the shell powder in a muffle furnace at 300 °C 2h, that is, the required shell powder raw material is obtained;

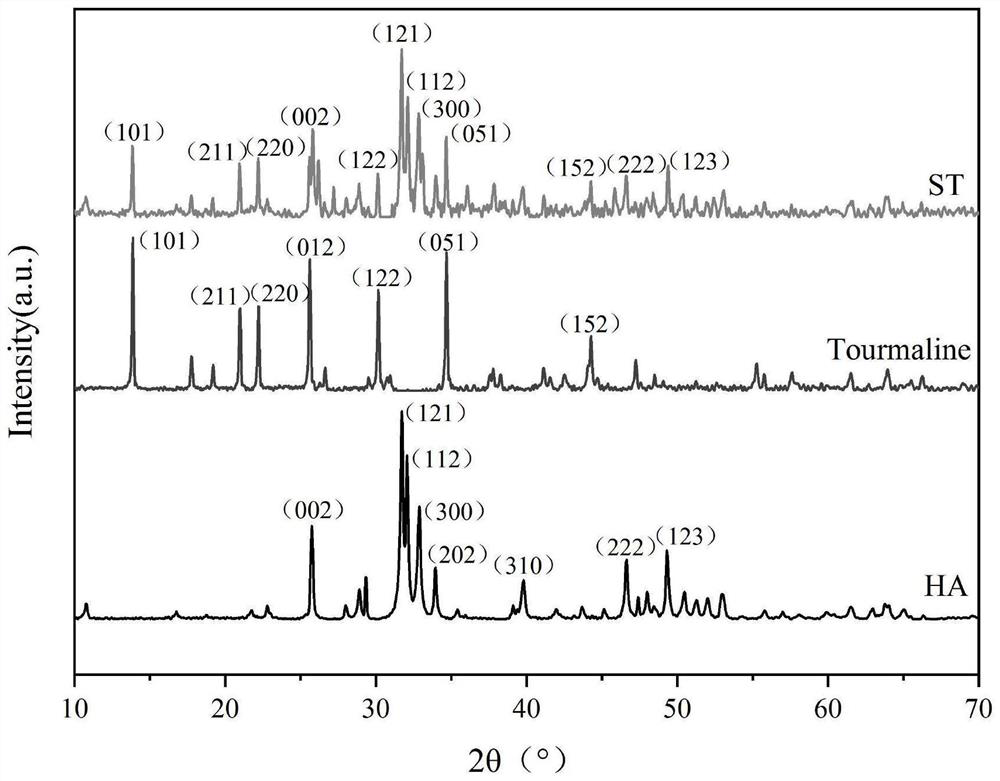

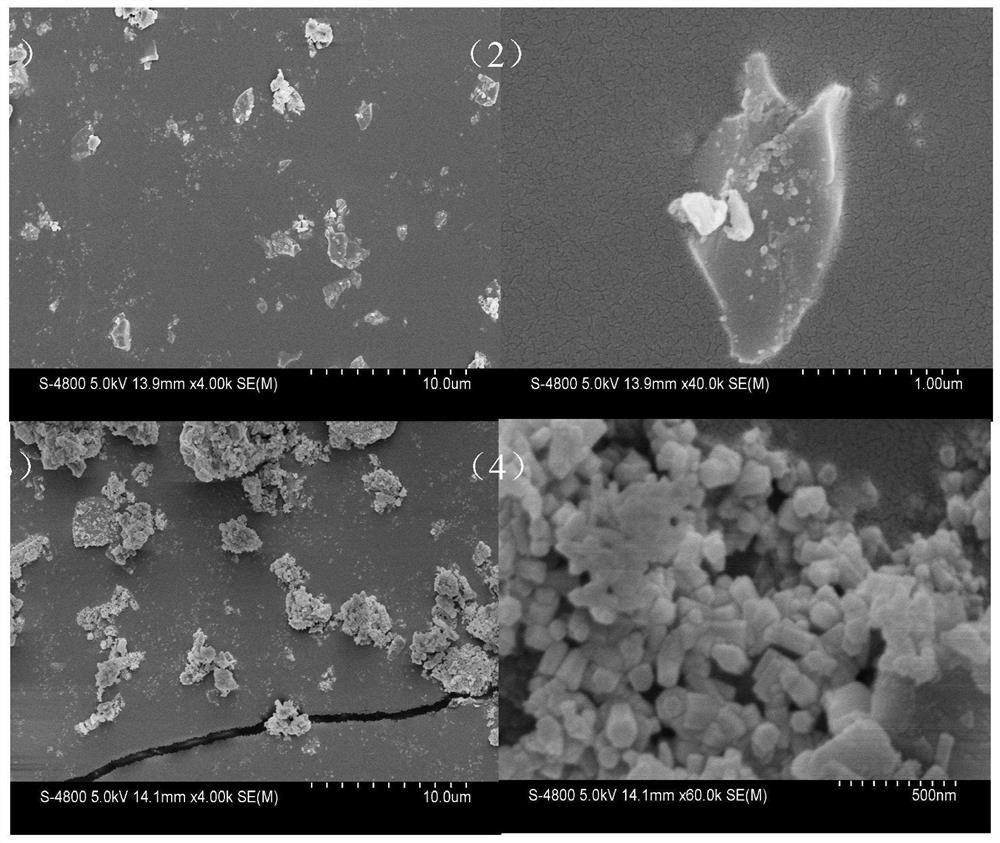

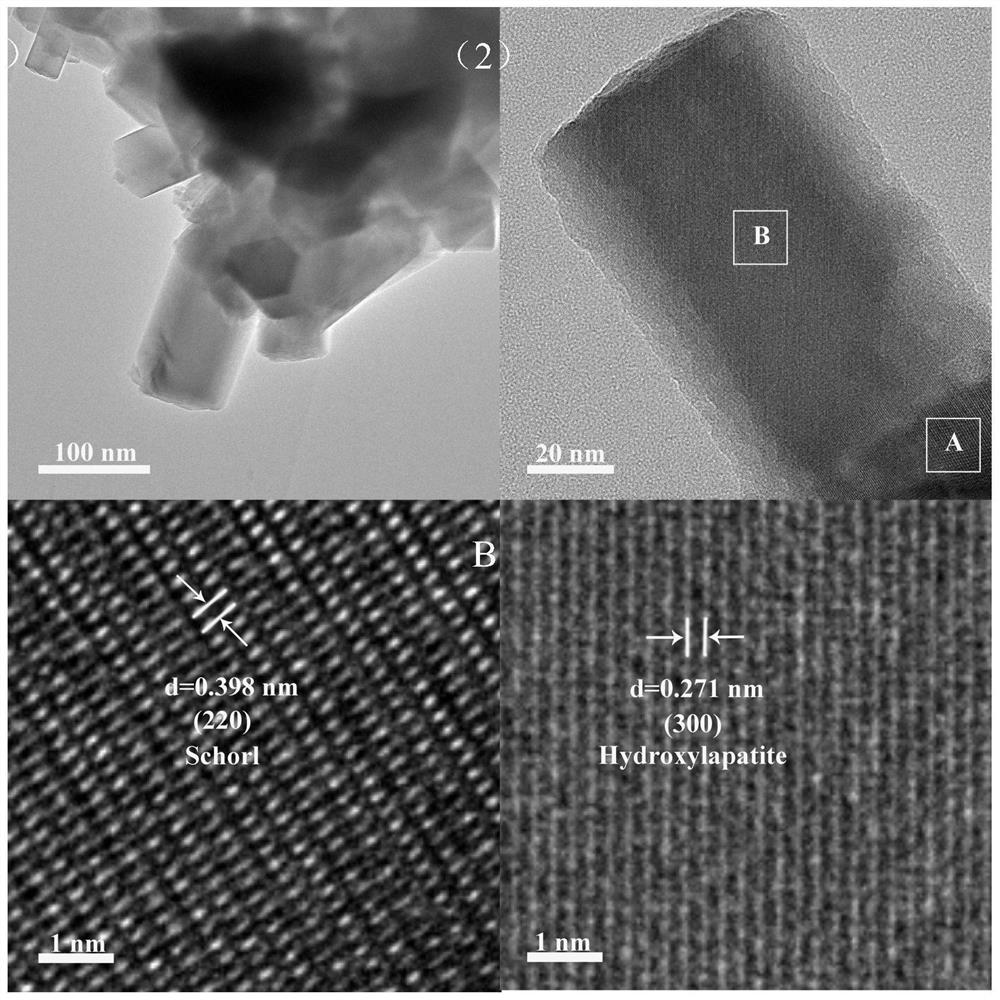

[0038] (2) Take 1.584g of ammonium hydrogen phosphate and dissolve it in 50ml of deionized water, add 2.000g of shell powder under stirring conditions, then add tourmaline powder in the ratio of shell:tourmaline=8:1, adjust pH=9 with ammonia water, room temperature Stir for 1 hour under the same conditions, then sonicate for 0.5 hours, and stir again for 1 hour; the particle size range of tourmaline particles used is 1-10 μm, and micron-sized tourmaline needs to be mixed with deionized water and then ultrasonically dispersed to reduce agglomeration. Add tourmaline dispersion directly during stirring;

[0039] (3) Pour the above mixture into a 100ml hydrotherma...

Embodiment 2

[0047] (1) Wash the natural clam shells with deionized water and crush them, put the shell fragments in a pulverizer for 5 minutes, pass the obtained shell powder through a 200-mesh sieve, and then calcinate the shell powder in a muffle furnace at 300 °C 2h, that is, the required shell powder raw material is obtained;

[0048] (2) Take 1.584g of ammonium hydrogen phosphate and dissolve it in 50ml of deionized water, add 2.000g of shell powder under stirring conditions, then add tourmaline powder in the ratio of shell:tourmaline=2:1, adjust pH=9 with ammonia water, room temperature Stir for 1 hour under the same conditions, then sonicate for 0.5 hours, and stir again for 1 hour; the particle size range of tourmaline particles used is 1-10 μm, and micron-sized tourmaline needs to be mixed with deionized water and then ultrasonically dispersed to reduce agglomeration. Add tourmaline dispersion directly during stirring;

[0049] (3) Pour the above mixture into a 100ml hydrotherma...

Embodiment 3

[0053] (1) Wash the natural clam shells with deionized water and crush them, put the shell fragments in a pulverizer for 5 minutes, pass the obtained shell powder through a 200-mesh sieve, and then calcinate the shell powder in a muffle furnace at 300 °C 2h, that is, the required shell powder raw material is obtained;

[0054] (2) Take 1.584g of ammonium hydrogen phosphate and dissolve it in 50ml of deionized water, add 2.000g of shell powder under stirring conditions, then add tourmaline powder in the ratio of shell:tourmaline=8:1, adjust pH=9 with ammonia water, room temperature Stir for 1 hour under the same conditions, then sonicate for 0.5 hours, and stir again for 1 hour; the particle size range of tourmaline particles used is 1-10 μm, and micron-sized tourmaline needs to be mixed with deionized water and then ultrasonically dispersed to reduce agglomeration. Add tourmaline dispersion directly during stirring;

[0055] (3) Pour the above mixture into a 100ml hydrotherma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com