A kind of compound/pva composite material and its preparation method and application

A technology of composite materials and complexes, applied in the direction of luminescent materials, chemical instruments and methods, single-component synthetic polymer rayon, etc., can solve the problems of difficult collection, separation, and poor processability of complexes, and achieve optimal application performance , application promotion, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of matrix membrane

[0046] (1) Preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex:

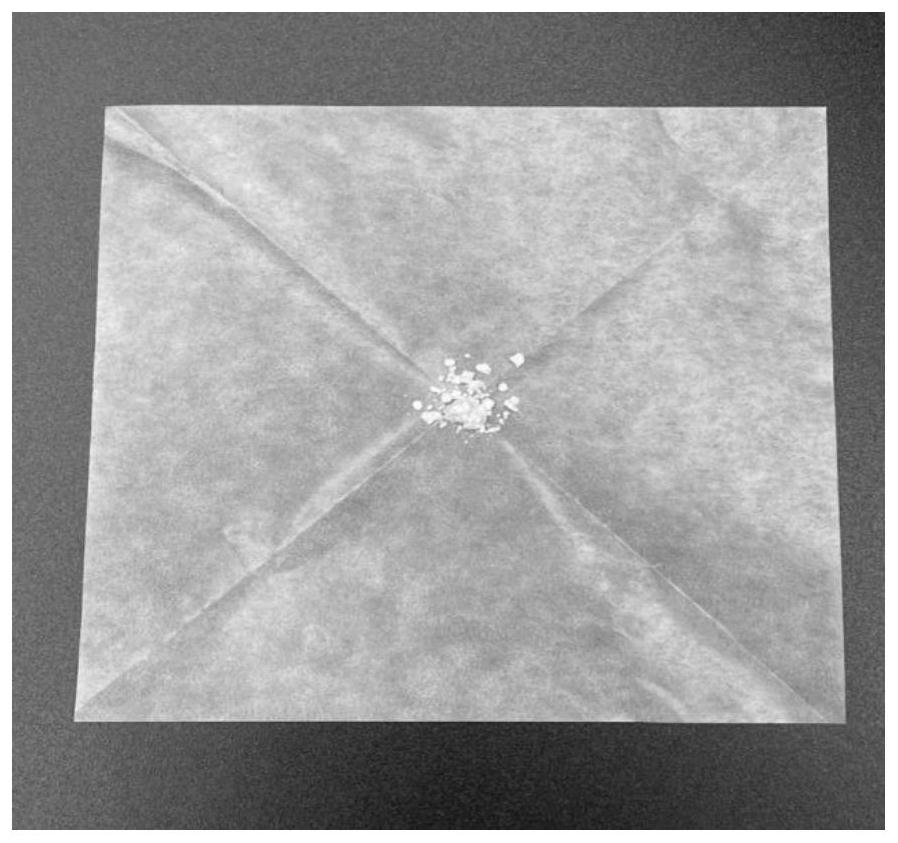

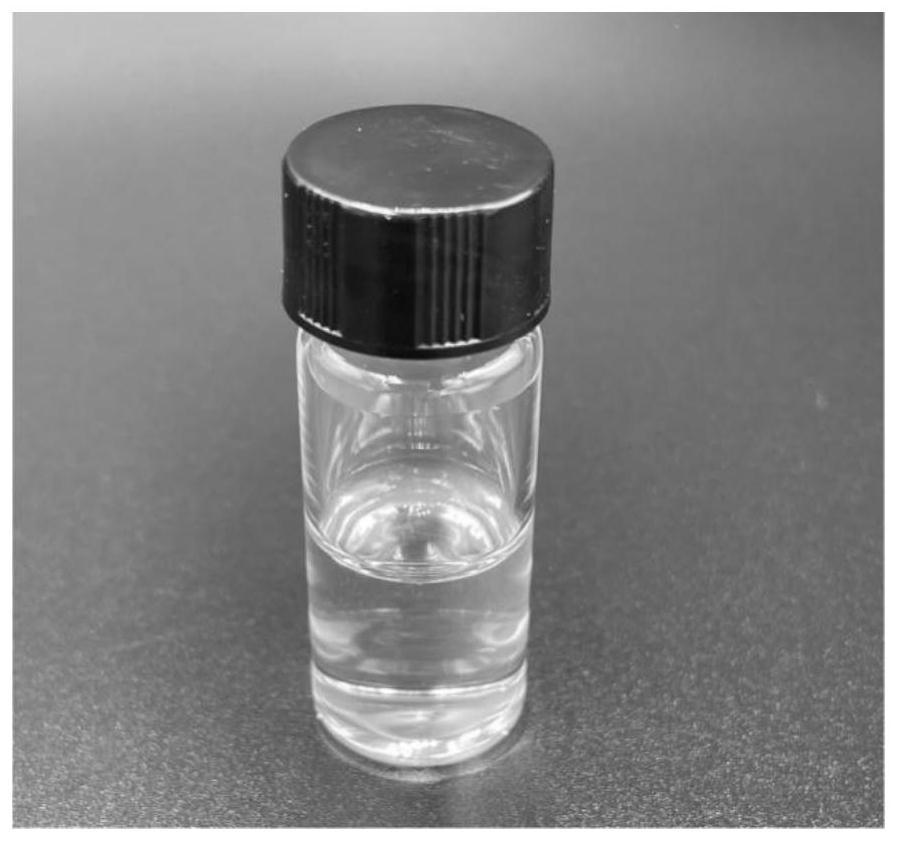

[0047] Cu(NO 3 ) 2 ·3H 2 O (60.4mg), 4-chloropyrazole (51.26mg) was dissolved in ethanol, and then diluted to 25mL with ethanol, so that the Cu(NO 3 ) 2 ·3H 2 The concentrations of O and 4-chloropyrazole were 0.01mol / L and 0.02mol / L, respectively. Then add 2mL of the above solution into a dry and clean hard thick-walled glass tube with an inner diameter of 8mm, and add 1mL of chlorobenzene into it, seal the tube with a hydrogen-oxygen flame machine, and put it in a constant temperature oven . The temperature was raised to 140° C. within 10 minutes, maintained for 12 hours, and then lowered to room temperature at a cooling rate of 5° C. / h. After opening the glass tube, a colorless and transparent Cl-α complex needle crystal was obtained, such as figure 1 shown.

[0048] (2) Preparation of PVA aqueous solution:

[0049] Add PVA powder into hot...

Embodiment 2

[0066] Preparation of matrix fibers

[0067] Step (1) Preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex and Step (2) preparation of PVA aqueous solution are the same as in Example 1.

[0068] (3) Preparation of matrix fiber:

[0069] Add the Cl-α luminescent complex to the PVA solution, stir for 14 hours, sonicate for 2 hours, and then degas to form a mixed solution, wherein the concentration of the Cl-α luminescent complex is 5 wt%; pour the above mixed solution into a syringe, Then extrude at a constant speed through a pump into a saturated sodium sulfate solution and salt out to form a matrix fiber.

Embodiment 3

[0071] Preparation of 3D printed devices

[0072] Step (1) The preparation of pyrazolyl ring trinuclear Cu(I)(Cl-α) luminescent complex is the same as in Example 1.

[0073] (2) Preparation of PVA aqueous solution:

[0074] Add PVA powder into hot water at 90° C., dissolve, stir, and react for 4 hours to obtain a PVA aqueous solution, wherein the concentration of PVA is 15 wt%.

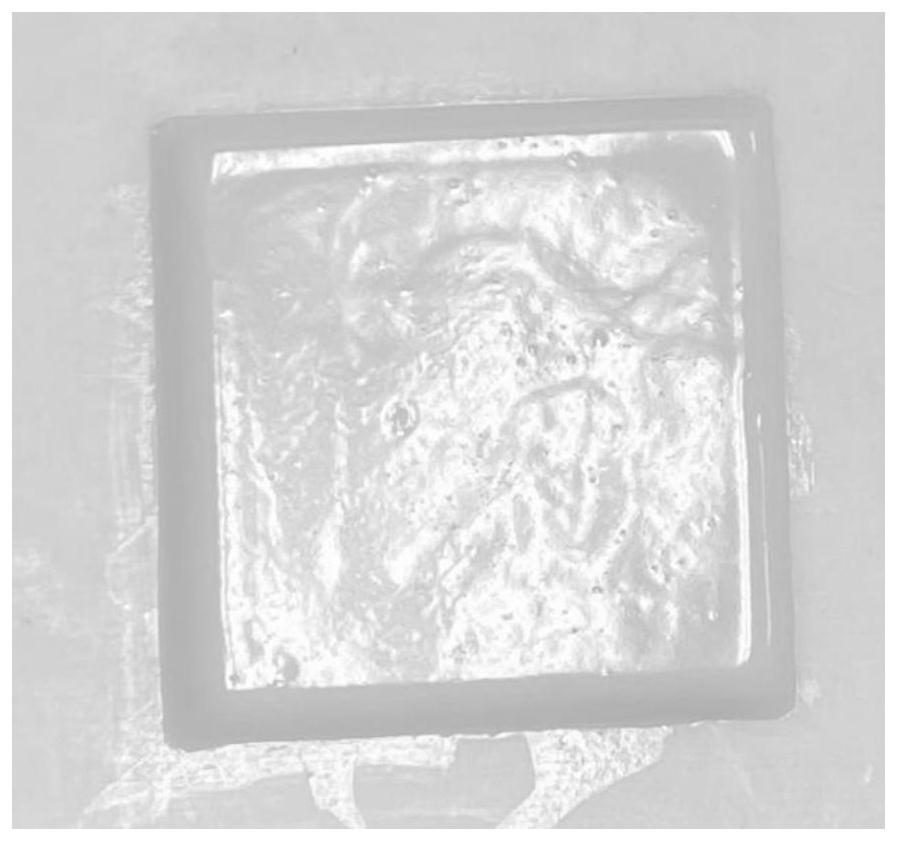

[0075] (3) Preparation of 3D printed devices:

[0076] Add the Cl-α luminescent complex to the PVA solution, stir for 14 hours, ultrasonicate for 2 hours, and then degas to form a mixed solution, in which the concentration of the Cl-α luminescent complex is 2 wt%. The above mixed solution is passed through an extrusion 3D The printer extrudes and prints devices of various shapes in a saturated sodium sulfate solution. Models of 3D printed devices of different shapes such as Figure 10 , Figure 11 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com