A kind of flame-retardant nylon material used for battery pack casing and preparation method thereof

A flame retardant nylon and battery pack technology, applied in the field of polymer materials, can solve problems such as flame retardant performance to be improved, battery module fire, heat runaway, etc., and achieve the effect of enhancing anti-corrosion effect, increasing carbon layer density, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

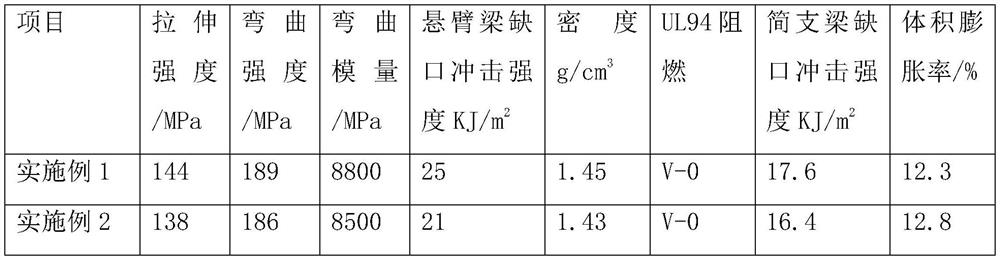

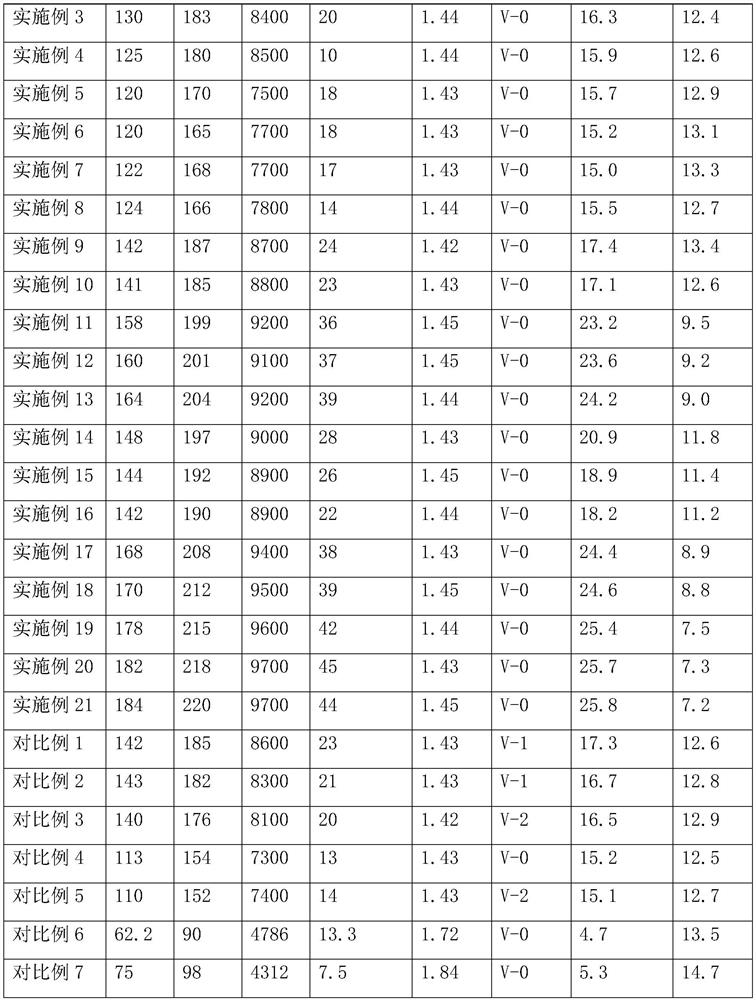

Examples

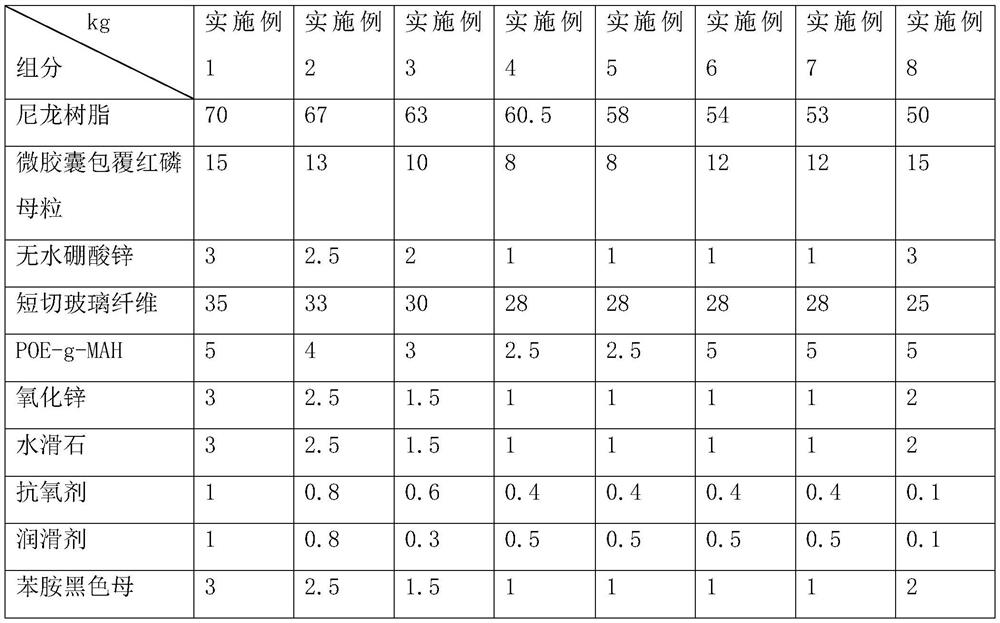

preparation example 1-8

[0038] In Preparation Example 1-8, cerium dioxide was selected from Bohuas Nano Technology (Ningbo) Co., Ltd.; poly-4-methyl-1-pentene was selected from Dongguan Suyun Plastic Co., Ltd.; expandable graphite was selected from Hongyue, Gongyi City Refractory Co., Ltd., the model is HY-SM; maleic anhydride grafted polyethylene is selected from Shenzhen Haian Plastic Chemical Co., Ltd., the model is PE1040.

preparation example 1

[0039] Preparation Example 1: (1) Mix 1kg red phosphorus with 1.5kg water, grind at a speed of 300r / min for 3h, dry in vacuum at 80°C for 3h, mix with 2kg ammonia water, 3.5kg tetraethyl orthosilicate, 2kg ethanol, 3kg Cerium dioxide is mixed, stirred for 5 hours, centrifuged, and vacuum-dried at 60°C for 10 hours. The purity of ceria is greater than 99.99%, and the density is 7.13g / cm 3 , the specific surface area is 90.86m 2 / g; (2) 3kg poly-4-methyl-1-pentene and 10kg step (1) gain are mixed, extrude, granulate, make microcapsules and coat red phosphorus masterbatch, and the temperature of a district is 175 ℃, the temperature in the second zone is 215 ℃, the temperature in the third zone is 235 ℃, the temperature in the fourth zone is 240 ℃, and the temperature in the fifth zone is 245 ℃.

preparation example 2

[0040] Preparation Example 2: (1) Mix 1.3kg of red phosphorus with 1.8kg of water, grind at a speed of 300r / min for 3h, dry in vacuum at 80°C for 3h, mix with 2.5kg of ammonia water, 4.5kg of ethyl orthosilicate, 2.3kg of Mix ethanol and 3.5kg ceria, stir for 5.5h, centrifuge, and vacuum dry at 60°C for 10h. The purity of ceria is greater than 99.99%, and the density is 7.13g / cm 3 , the specific surface area is 90.86m 2 / g;

[0041] (2) 4kg poly-4-methyl-1-pentene and 15kg step (1) gain are mixed, extrude, granulate, make microcapsule coating red phosphorus masterbatch, the temperature of one district is 175 ℃, two The temperature in the zone is 215°C, the temperature in the third zone is 235°C, the temperature in the fourth zone is 240°C, and the temperature in the fifth zone is 245°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com