A kind of production process of tinned copper wire for preventing tinned layer from falling off

A technology of tinned copper wire and production process, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of affecting the use effect and service life of products, affecting the production quality of tinned copper wire, tinning Poor layer adhesion and other problems to achieve the effect of avoiding copper exposure, uniform tin plating without falling off, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

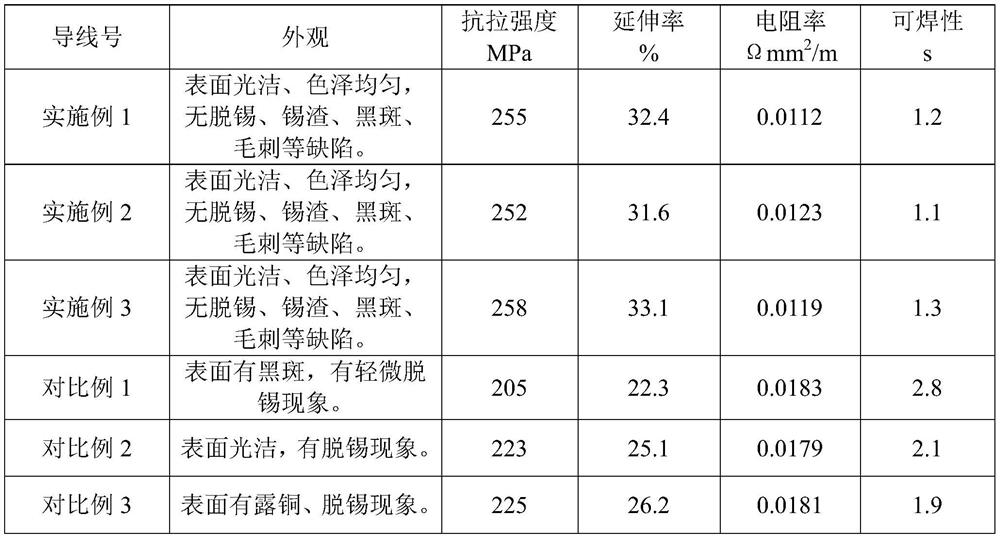

Examples

Embodiment 1

[0027] A production process of tin-plated copper wire that avoids the tin-plated layer falling off. In terms of mass percentage, the copper content of the copper wire is 99.91-99.99%, and the tin content of the tin-plated layer is greater than 99.99%. The production process is completed in the early stage of preparations For example, the replacement of sandpaper, the preparation of acid solution, the setting of hot water temperature, and the setting of drying oven temperature are all completed in a space filled with nitrogen, which includes the following steps:

[0028] S1. Pay-off: Select the copper wire with smooth surface and pass it through the magnetic powder tension pay-off machine to pay off the wire to get the copper wire;

[0029] S2. Grinding: pass the copper wire in step S1 through a grinding machine equipped with 70-mesh sandpaper to grind the surface;

[0030] S3. Pickling: after the copper wire polished in step S2 is cleaned in a pickling tank equipped with pickl...

Embodiment 2

[0038] A production process of tin-plated copper wire that avoids the tin-plated layer falling off. In terms of mass percentage, the copper content of the copper wire is 99.91-99.99%, and the tin content of the tin-plated layer is greater than 99.99%. The production process is completed in the early stage of preparations For example, the replacement of sandpaper, the preparation of acid solution, the setting of hot water temperature, and the setting of drying oven temperature are all completed in a space filled with nitrogen, which includes the following steps:

[0039] S1. Pay-off: Select the copper wire with smooth surface and pass it through the magnetic powder tension pay-off machine to pay off the wire to get the copper wire;

[0040] S2. Grinding: pass the copper wire in step S1 through a grinding machine equipped with 75-grit sandpaper to grind the surface;

[0041] S3. Pickling: after the copper wire polished in step S2 is cleaned in a pickling tank equipped with pickl...

Embodiment 3

[0049] A production process of tin-plated copper wire that avoids the tin-plated layer from falling off. In terms of mass percentage, the copper content of the copper wire is 99.91-99.99%, and the tin content of the tin-plated layer is greater than 99.99%. For example, the replacement of sandpaper, the preparation of acid solution, the setting of hot water temperature, and the setting of drying oven temperature are all completed in a space filled with nitrogen, which includes the following steps:

[0050] S1. Pay-off: Select the copper wire with smooth surface and pass it through the magnetic powder tension pay-off machine to pay off the wire to get the copper wire;

[0051] S2. Grinding: pass the copper wire in step S1 through a grinding machine equipped with 80-mesh sandpaper to grind the surface;

[0052] S3. Pickling: after the copper wire polished in step S2 is cleaned in a pickling tank equipped with pickling solution, the acid solution is wiped off;

[0053] S4. Washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com