Pretreatment method of titanium substrate for electrode

A titanium base and pretreatment technology, which is applied in the field of environmental protection wastewater treatment, can solve problems such as difficulty in meeting requirements, and achieve the effects of improving electrode life, easy bonding, and increasing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

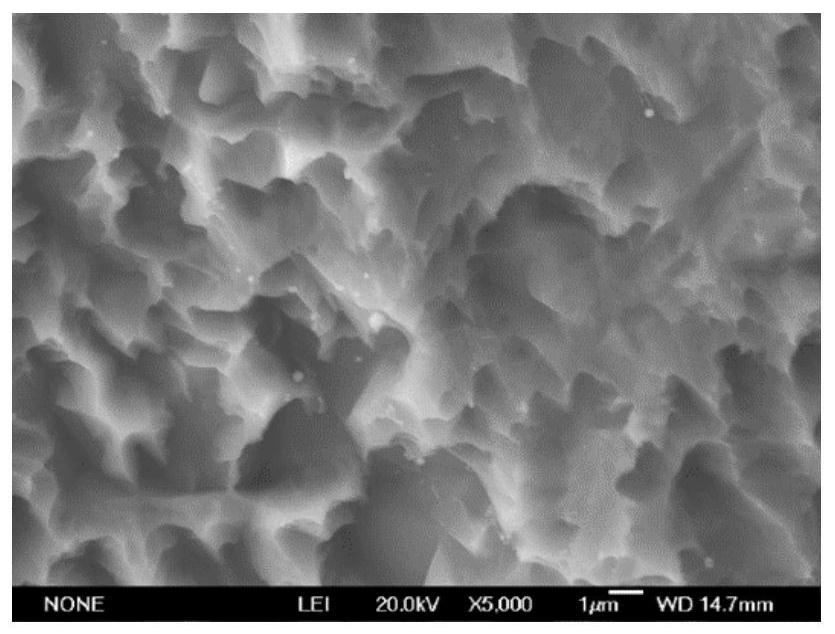

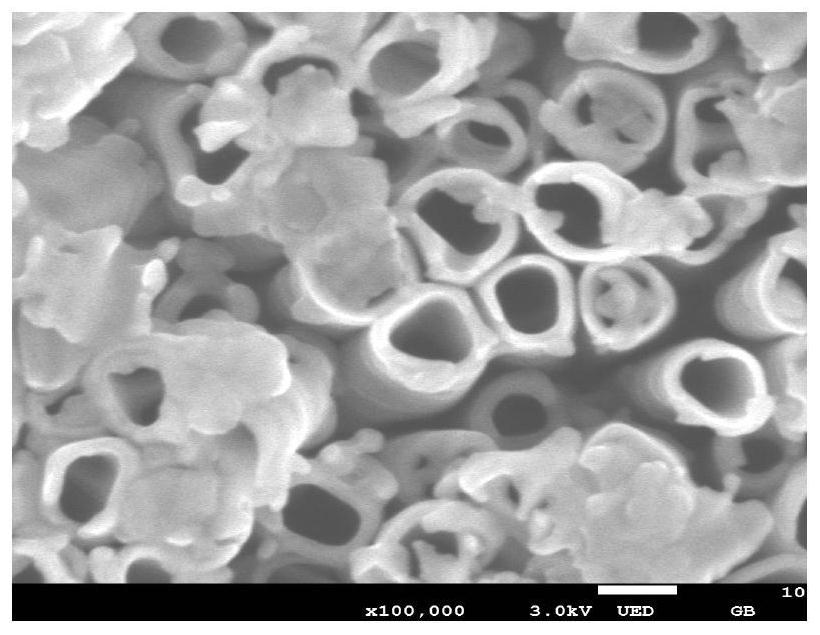

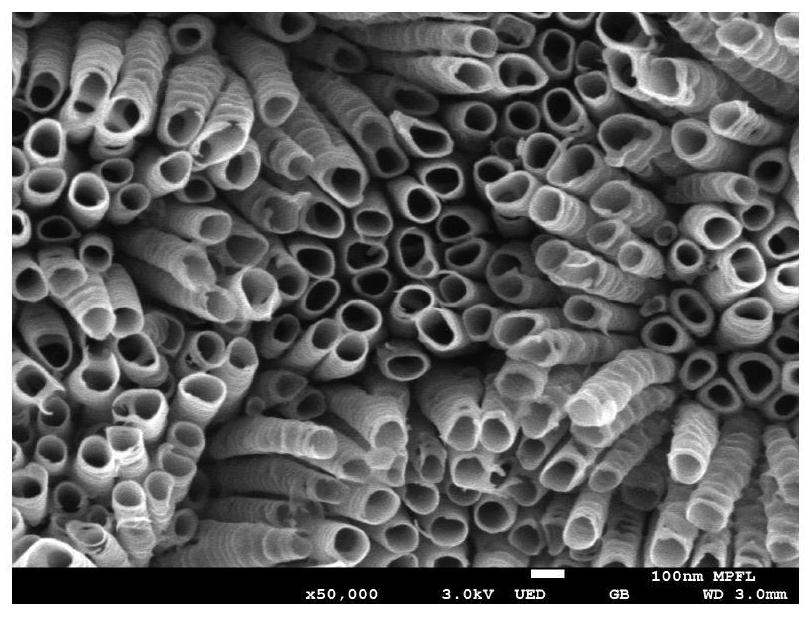

[0038] Put the titanium mesh in 10% oxalic acid solution and boil for 60min. The surface of the titanium mesh base forms an uneven honeycomb pitted surface, such as figure 1 shown. Put the above-mentioned titanium substrate boiled with oxalic acid in the electrolyte, wherein the volume ratio of ethylene glycol to water is 5:1, and the mass concentration of ammonium fluoride is 0.5%. The titanium mesh boiled with oxalic acid is used as the anode, and another titanium Use a net as the cathode, keep the distance between the two electrodes 2cm, electrolyze for 2.5h at a voltage of 30V, and obtain a surface structure such as figure 2 Shown is a titanium substrate whose surface has a nanotube array structure but is partially covered by inclusions. The titanium substrate was ultrasonically cleaned in 3% hydrochloric acid solution for 1 min to obtain the following image 3 In the titanium substrate with the structure shown, the substrate is covered by a neat array of titanium nano...

Embodiment 2

[0040] Place the titanium sheet in 15% oxalic acid solution and boil for 10 minutes. Put the above-mentioned titanium substrate boiled with oxalic acid in the electrolyte, wherein the volume ratio of ethylene glycol to water is 10:1, and the mass concentration of ammonium fluoride is 1.0%. The titanium sheet boiled with oxalic acid is used as the anode, and the platinum sheet is used as the cathode. , keep the distance between the two electrodes 1cm, electrolyze at 70V for 0.5h. The titanium substrate was ultrasonically cleaned in 3% hydrochloric acid solution for 10 minutes, and the substrate was covered by a tidy array of titanium nanotubes, and this structure was the pretreated titanium substrate.

Embodiment 3

[0042] Place the titanium rod in 2% oxalic acid solution and boil for 30min. Put the above-mentioned titanium substrate boiled with oxalic acid in the electrolyte, wherein the volume ratio of ethylene glycol to water is 2:1, and the mass concentration of ammonium fluoride is 0.8%. The titanium rod boiled with oxalic acid is used as the anode, and the stainless steel sheet is used as the cathode , keep the distance between the two electrodes 5cm, electrolyze at 50V for 1h. The titanium substrate was ultrasonically cleaned in 3% hydrochloric acid solution for 5 minutes, and the substrate was covered by a neat array of titanium nanotubes, and this structure was the pretreated titanium substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com