Concentrated fermented tea vinegar paste with high-ester flavor, and manufacture method of concentrated fermented tea vinegar paste

A production method and technology of fermented tea, which is applied in the preparation of vinegar, tea, tea extraction, etc., can solve the problems of difficulty in retaining the aroma of raw materials, complicated raw material processing technology, and single flavor of the product, so as to improve the single taste and avoid burnt taste , Delicate taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

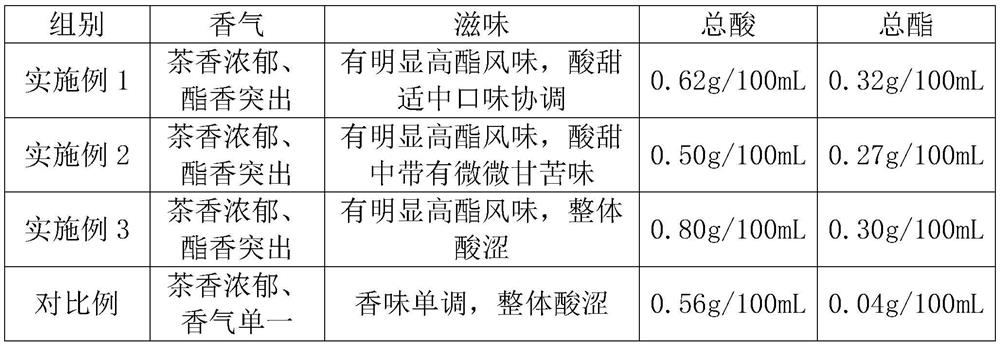

Examples

Embodiment 1

[0034] A concentrated fermented tea vinegar paste with high-ester flavor, comprising the following raw materials in parts by weight: 500 parts of green tea, 400 parts of black tea, 100 parts of wolfberry, 50 parts of cypress kernels, 50 parts of red dates, 50 parts of dried hawthorn, 2 parts of aspartame 2 parts, 2 parts of potassium sorbate, 5 parts of aroma-producing yeast, 20 parts of acetic acid bacteria, 0.2 part of pectinase, 0.05 part of cellulase, and the classification of described aroma-producing yeast is called ester-producing yeast BTL-YO1 Hansenula anomala BTL-Y01, the preservation number is CCTCC NO:M2013115, the acetic acid bacteria is preserved in the China Center for Type Culture Collection, and its classification is named Acetobacer pasteurianusDY4, and the preservation number is CCTCC NO:M2015462.

[0035] The preparation method of the concentrated fermented tea vinegar paste of high-ester flavor comprises the steps:

[0036] (1) Raw material pretreatment: m...

Embodiment 2

[0053] A concentrated fermented tea vinegar paste with high-ester flavor, comprising the following raw materials in parts by weight: 600 parts of green tea, 500 parts of black tea, 150 parts of wolfberry, 100 parts of cypress kernels, 100 parts of red dates, 100 parts of dried hawthorn, 5 parts of aspartame 5 parts, 5 parts of potassium sorbate, 5 parts of aroma yeast, 15 parts of acetic acid bacteria, 0.36 part of pectinase, 0.1 part of cellulase, the classification of described aroma yeast is called ester-producing yeast BTL-YO1 Hansenula anomala BTL-Y01, the preservation number is CCTCC NO:M2013115; the acetic acid bacterium is preserved in the China Center for Type Culture Collection, and its classification is named Acetobacer pasteurianusDY4, and the preservation number is CCTCC NO:M2015462.

[0054] The preparation method of the concentrated fermented tea vinegar paste of high-ester flavor comprises the steps:

[0055] (1) Raw material pretreatment: make tea soup, wolfbe...

Embodiment 3

[0072] A concentrated fermented tea vinegar paste with high-ester flavor, comprising the following raw materials in parts by weight: 500 parts of green tea, 500 parts of black tea, 100 parts of wolfberry, 80 parts of cypress kernels, 80 parts of red dates, 80 parts of dried hawthorn, 4 parts of aspartame 3 parts, 3 parts of potassium sorbate, 5 parts of aroma-producing yeast, 25 parts of acetic acid bacteria, 0.28 part of pectinase, 0.08 part of cellulase, and the classification of described aroma-producing yeast is called ester-producing yeast BTL-YO1 Hansenula anomala BTL-Y01, the preservation number is CCTCC NO:M2013115; the acetic acid bacterium is preserved in the China Center for Type Culture Collection, and its classification is named Acetobacer pasteurianusDY4, and the preservation number is CCTCC NO:M2015462.

[0073] A kind of preparation method of the concentrated fermented tea vinegar cream of above-mentioned high-ester flavor, comprises the steps:

[0074] (1) Raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com