Cheap metal catalyst and application thereof in selective hydrogenation reaction of alkyne compounds

A technology of metal catalyst and alkyne compound, which is applied to cheap metal catalyst and its application field in selective hydrogenation reaction of alkyne compound, can solve the problems of harsh reaction conditions, limitation of cheap metal catalyst, cumbersome preparation process, etc. The effect of simple operation, improved catalytic activity and selectivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

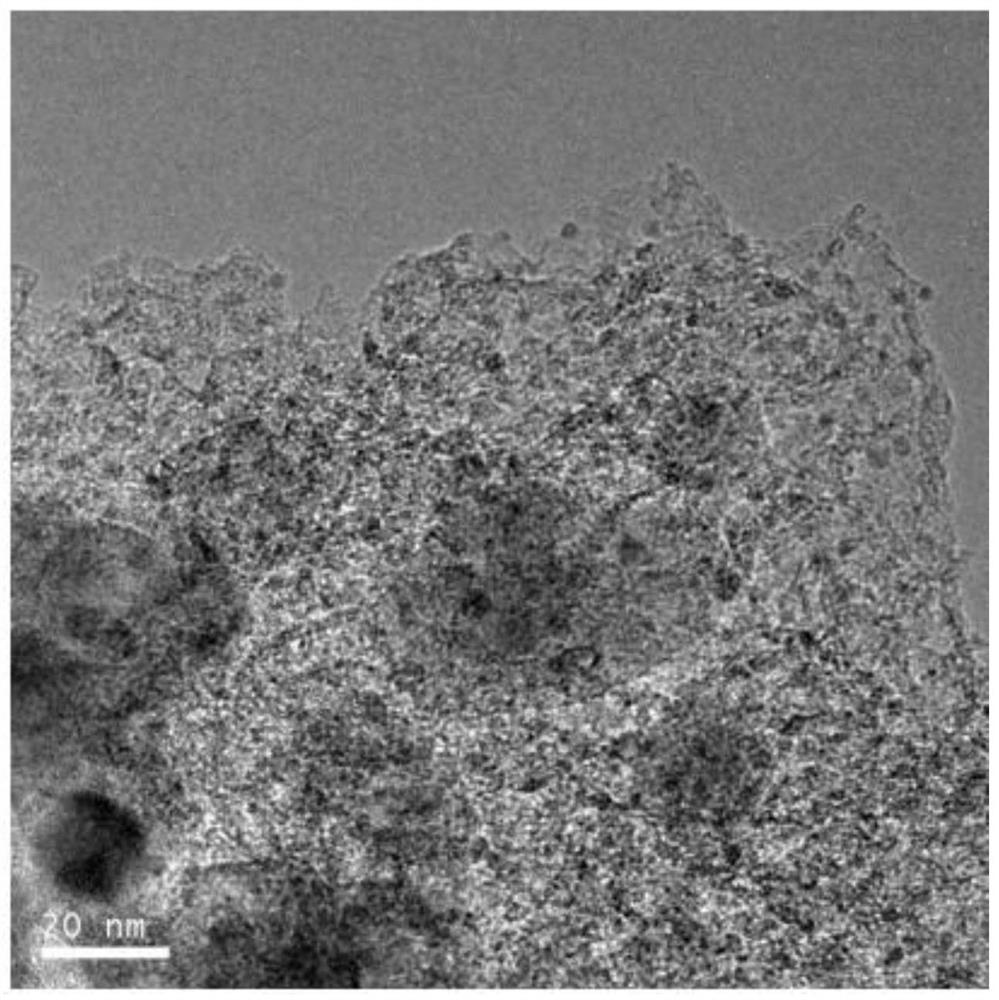

[0021] Embodiment 1 is based on TiO 2 -Vo supported Ni heterogeneous catalyst

[0022] Add 30mL of ethylene glycol and 1mL of titanium tetrachloride into a 50ml polytetrafluoroethylene kettle, stir at room temperature for ten minutes, add 1mL of deionized water, stir for ten minutes and then heat-treat at 150°C for 6 hours, and filter the suspension with suction at 60 Dry under vacuum at ℃ for 12h to obtain TiO 2 (B) Carrier. The above TiO 2 (B) Under a nitrogen atmosphere, heat up to 800°C in a nitrogen furnace and calcinate for 3 hours, and finally cool down to room temperature naturally to obtain the TiO with oxygen vacancies 2 material, label it TiO 2 -Vo carrier.

[0023] TiO 2 -Vo carrier 100mg into a 100ml beaker, add 20mL of water and 1mL of pre-constituted NiCl 2 Aqueous solution (NiCl 2 The concentration of the aqueous solution is 10mg / mL), and it is dried under the condition of 80°C oil bath, and the obtained solid is ground, and finally the temperature is r...

Embodiment 2

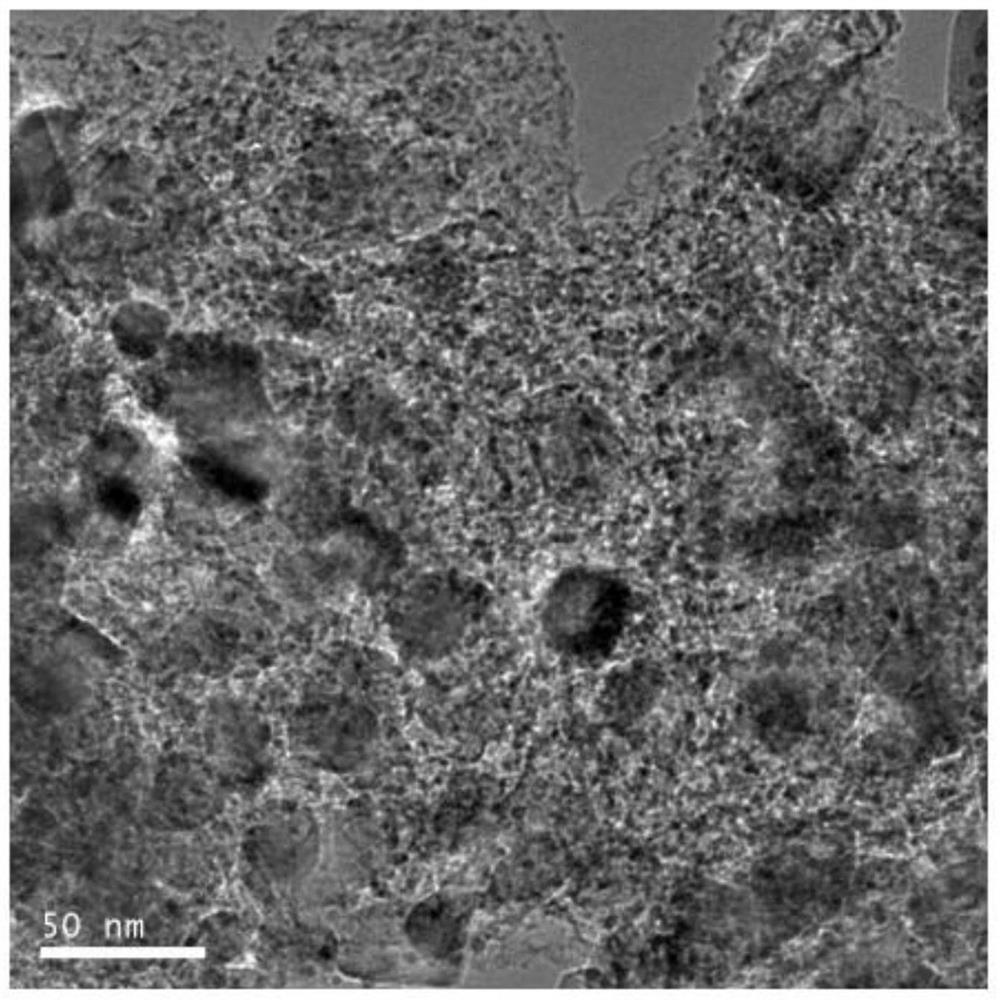

[0024] Embodiment 2 is based on TiO 2 -Vo supported Ni heterogeneous catalyst

[0025] TiO 2 -The preparation steps of the Vo carrier were repeated in Example 1.

[0026] Add 100mg TiO to a 100ml beaker 2 -Vo carrier and 20mL of deionized water, sonicate for 10min to a homogeneous mixture, add 1mL of pre-configured NiCl 2 Aqueous solution (NiCl 2 The concentration of the aqueous solution is 10mg / mL), after ultrasonication for 10min, add 1mL of freshly prepared sodium borohydride aqueous solution and continue ultrasonication for 30min (the concentration of sodium borohydride aqueous solution is 15mg / mL), Ni 2+ Reduced to simple Ni, suction filtered, and the filter residue was washed with water and dried to obtain TiO 2 -Vo supported Ni catalyst.

Embodiment 3

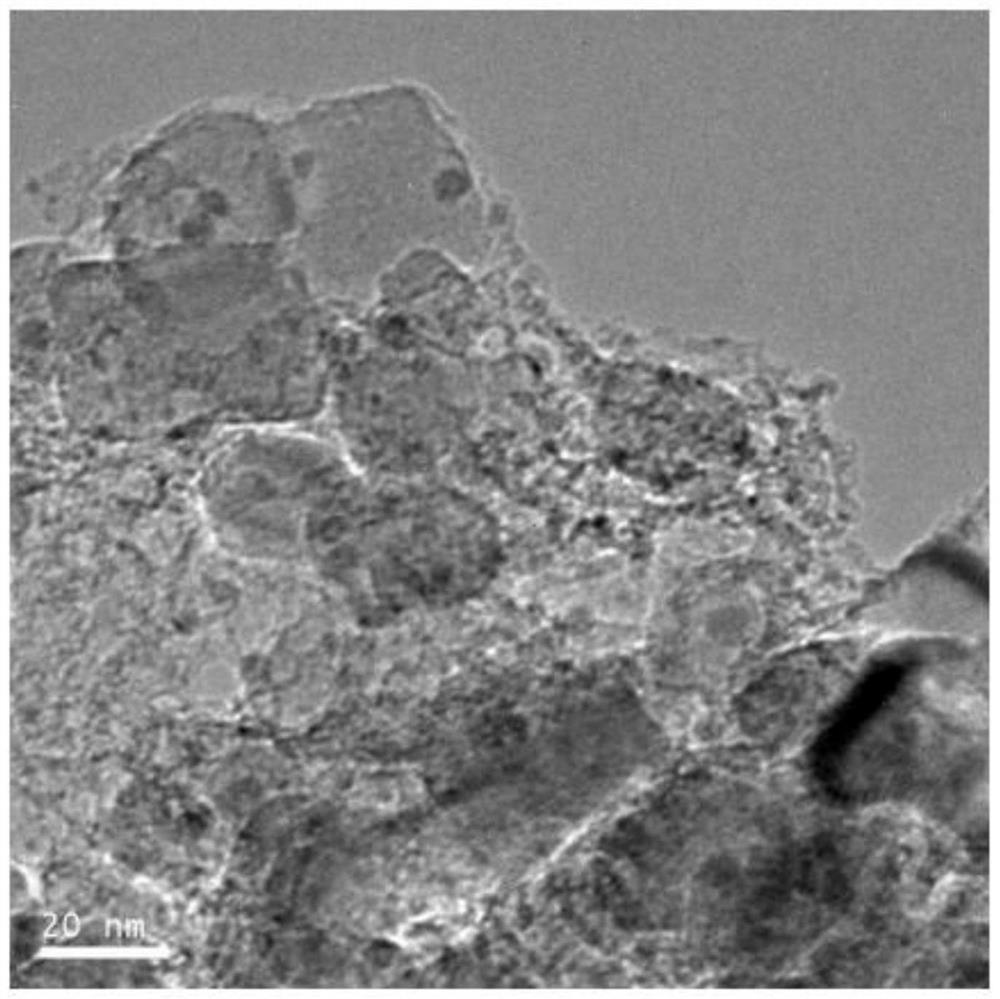

[0027] Embodiment 3 is based on TiO 2 -Vo supported Ni heterogeneous catalyst

[0028] TiO 2 -The preparation steps of the Vo carrier were repeated in Example 1.

[0029]Evenly stack 10mg of nickelocene powder on the front of the porcelain boat, and spread 100mg of TiO on the back of the porcelain boat 2 -Vo carrier, then place the ceramic boat in a nitrogen furnace, and feed nitrogen into the nitrogen furnace. The nitrogen gas flow first contacts with the nickelocene particles and then with the TiO 2 -Vo carrier contact, in a nitrogen atmosphere, heat up to 400 ° C in a nitrogen furnace and calcined for 3 hours, and finally cool down to room temperature naturally to obtain a TiO-based 2 -Vo supported Ni heterogeneous catalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com