Novel transition metal telluride with adjustable superconductivity and charge density wave and preparation method thereof

A technology of superconductivity and charge density, applied in the direction of metal selenide/telluride, selenium/telluride compound, chemical instruments and methods, etc., can solve the problem of low superconducting temperature, achieve Tc improvement, uniform distribution, and easy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

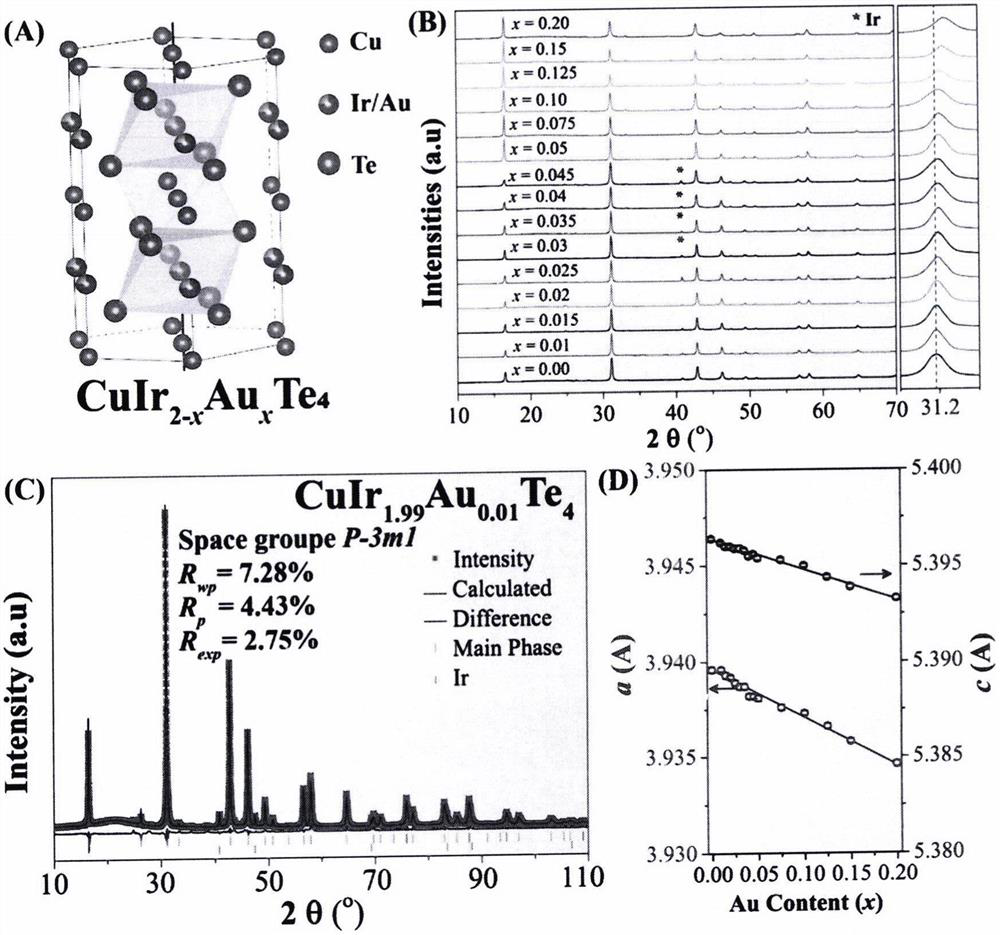

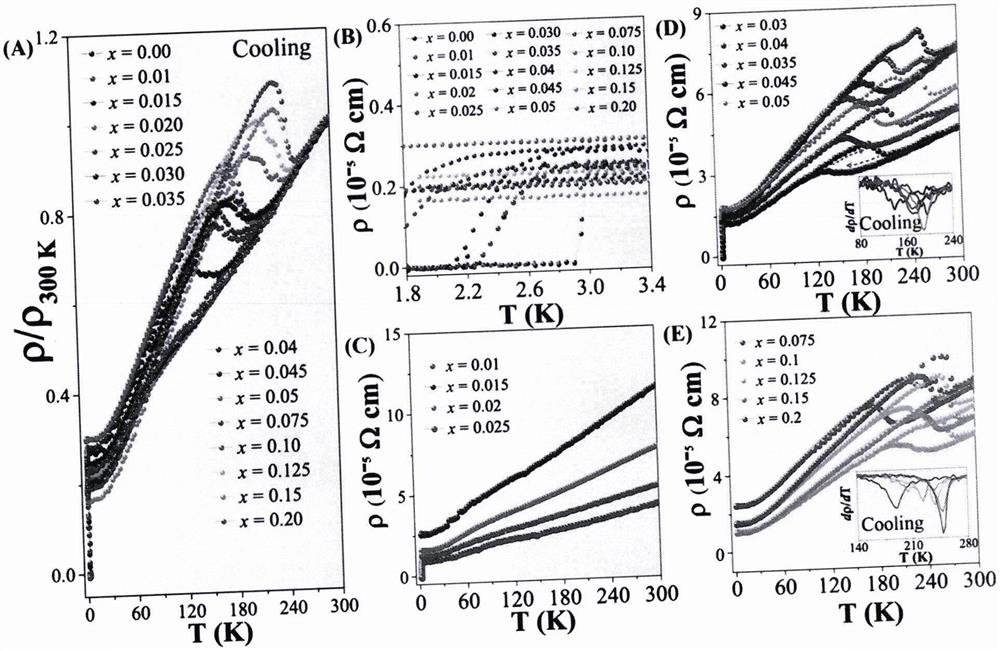

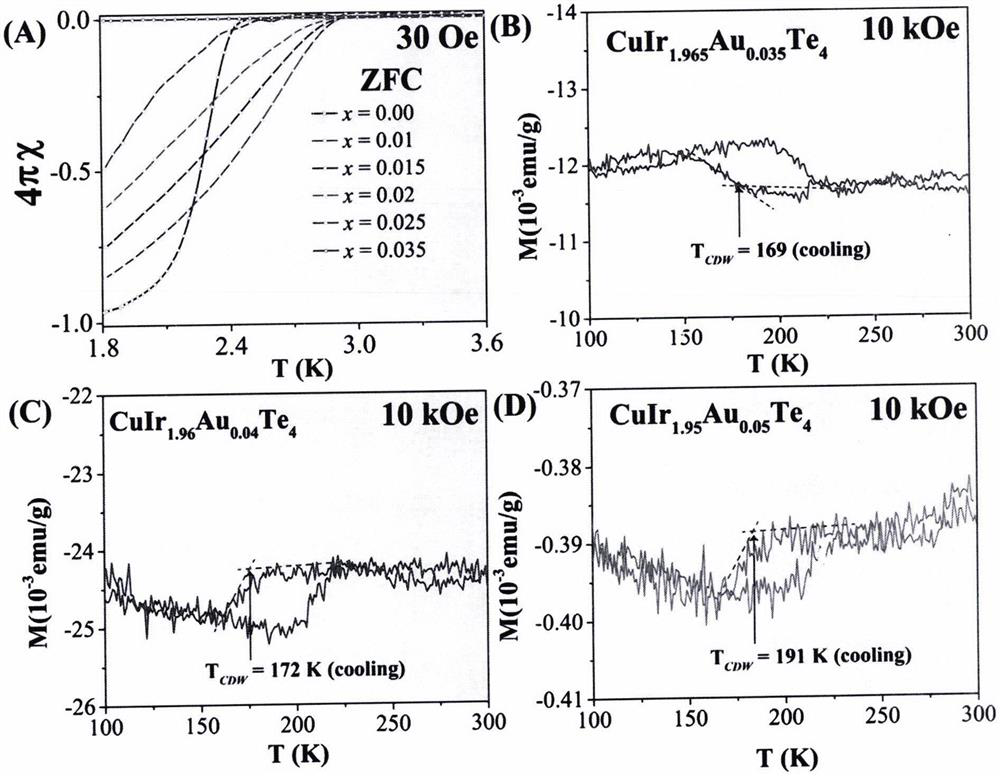

[0028] Accurately weigh 0.0198g Cu, 0.1186g Ir, 0.1607g Te and 0.009g Au raw materials, place them in a quartz tube after fully grinding, and pump the quartz tube containing the fully ground raw materials to a vacuum degree of 1×10 -5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 850°C for 120 hours of calcination, then open the quartz tube, fully grind the obtained powder and press it into tablets; Put it in the quartz tube again, and evacuate the quartz tube to a vacuum of 1×10 - 5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 800 °C for 240 h to obtain CuIr 1.985 Au 0.015 Te 4 Sample; then use X-ray powder diffraction (PXRD) to determine the purity of the sample; finally, the physical properties of the obtained polycrystalline sample material will be tested by the Physical Comprehensive Testing System (PPMS): mainly including electrical conductivity, magnetic...

Embodiment 2

[0030] Accurately weigh 0.0198g Cu, 0.1165g Ir, 0.1607g Te and 0.0031g Au raw materials, place them in a quartz tube after fully grinding, and pump the quartz tube containing the fully ground raw materials to a vacuum degree of 1×10 -5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 850°C for 120 hours of calcination, then open the quartz tube, fully grind the obtained powder and press it into tablets; Put it in the quartz tube again, and evacuate the quartz tube to a vacuum of 1×10 - 5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 800 °C for 240 h to obtain CuIr 1.95 Au 0.05 Te 4Sample; then use X-ray powder diffraction (PXRD) to determine the purity of the sample; finally, the physical properties of the obtained polycrystalline sample material will be tested by the Physical Comprehensive Testing System (PPMS): mainly including electrical conductivity, magnetic s...

Embodiment 3

[0032] Accurately weigh 0.0198g Cu, 0.1135g Ir, 0.1606g Te and 0.0061g Au raw materials, place them in a quartz tube after fully grinding, and pump the quartz tube containing the fully ground raw materials to a vacuum degree of 1×10 -5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 850°C for 120 hours of calcination, then open the quartz tube, fully grind the obtained powder and press it into tablets; Put it in the quartz tube again, and evacuate the quartz tube to a vacuum of 1×10 - 5 Torr, and seal the tube with an acetylene flame; then place the sealed quartz tube in a box furnace at 800 °C for 240 h to obtain CuIr 1.9 Au 0.1 Te 4 Sample; then use X-ray powder diffraction (PXRD) to determine the purity of the sample; finally, the physical properties of the obtained polycrystalline sample material will be tested by the Physical Comprehensive Testing System (PPMS): mainly including electrical conductivity, magnetic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com