Self-lubricating film material and preparation method thereof

A self-lubricating film and film material technology, applied in the field of anti-friction materials, can solve the problems of poor anti-corrosion performance, low applicable temperature of self-lubricating film, unstable friction coefficient, etc., and achieve strong anti-corrosion performance, high applicable temperature and stable friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

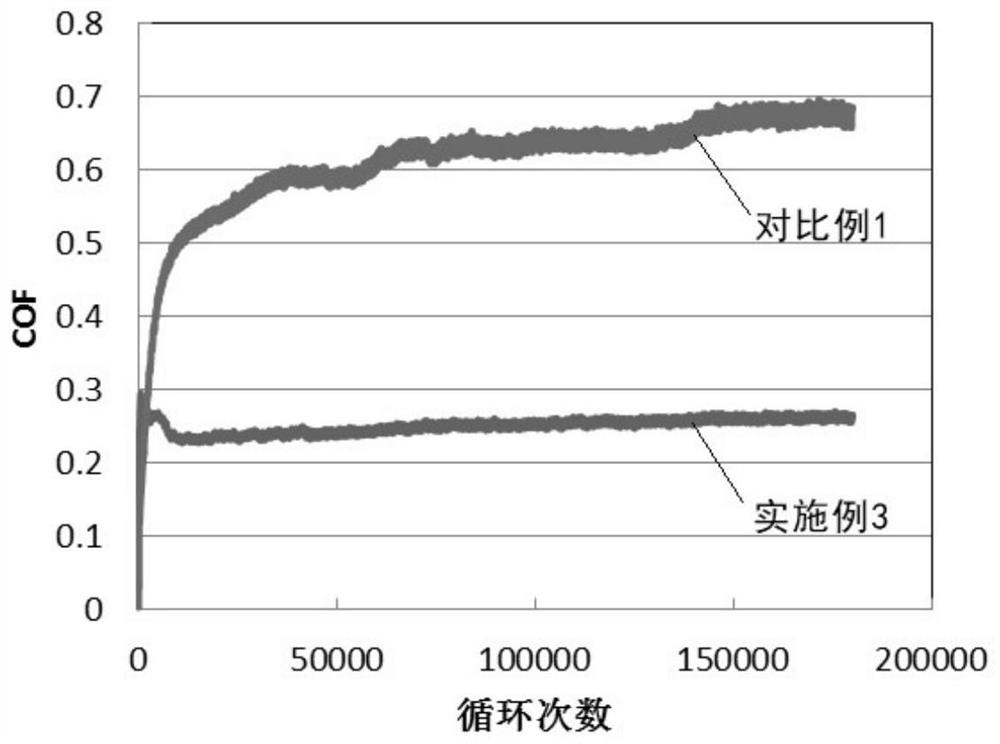

[0055] The embodiment of the present application also provides a preparation method of a self-lubricating film material, comprising the following steps: adding 30 to 40 parts of diluent to 100 parts of basic slurry by mass parts, and then weighing 20 to 35 parts of functional The auxiliary material is added to the diluted base slurry, and dispersed at a speed of 800-1300r / min for 20-30 minutes to obtain a self-lubricating film material; the mass percent concentration of hexagonal boron nitride in the self-lubricating film material prepared by this application is 30 ~40wt%, the prepared self-lubricating film material is solidified by air spraying at low temperature to form a self-lubricating film layer. The friction coefficient of the formed self-lubricating film layer is 0.2-0.28, the adhesion is 0-1 grade, and it is resistant to neutral salt spray The time is not less than 240h.

[0056] In terms of parts by mass, each basic slurry consists of 40-80 parts of polymer resin, 0....

Embodiment 1

[0061] Embodiment 1 of the present application provides a kind of preparation method of self-lubricating film material, comprises the following steps:

[0062] (1) Preparation of basic slurry: 90g of acrylic resin, 1.2g of propylene glycol methyl ether, 4g of N,N-dimethylethanolamine, 0.6g of polymer non-ionic dispersant 6208 / 60, 0.8 g water-based defoamer 810, 1.0g of white carbon black A200, 60g of pigment and filler 189 and 12g of water-based wetting agent 4100, mixed evenly to obtain the basic slurry;

[0063] (2) According to each 1g as a portion, weigh 100g of the base slurry prepared above, add 30g of deionized water to dilute, and then add 20g of hexagonal nitride with a particle size of 5-15μm to the diluted base slurry. Boron is dispersed by high-speed dispersing equipment with a dispersing disc to obtain a self-lubricating film material. The rotating speed of the dispersing equipment is 1250r / min, and the dispersing time is 25min.

[0064] The self-lubricating film...

Embodiment 2

[0066] Embodiment 2 of the present application provides a kind of preparation method of self-lubricating film material, comprises the following steps:

[0067] (1) prepare base slurry: the process that embodiment 2 prepares base slurry is the same as embodiment 1;

[0068] (2) According to each 1g as a portion, weigh 100g of the basic slurry prepared in the above-mentioned Example 1, add 40g of deionized water to dilute, and then add 35g of 5-15μm particle size to the diluted basic slurry. The hexagonal boron nitride is dispersed by a high-speed dispersing device with a dispersing disc to obtain a self-lubricating film material. The rotating speed of the dispersing device is 900r / min, and the dispersing time is 25 minutes.

[0069] The self-lubricating film material prepared in Example 2 was air-sprayed on the steel plate, baked in an oven at 80° C. for 30 minutes, then taken out, and solidified to form a self-lubricating film layer with a mass percent concentration of hexagon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com