Method for separating and purifying rhodium in impurity-containing rhodium solution

A purification method and solution technology, applied in the field of rhodium extraction, can solve the problems of long precipitation operation time, inability to remove palladium, limited separation and purification effect, etc., and achieve the effects of easy filtration and rinsing, high specific gravity, convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

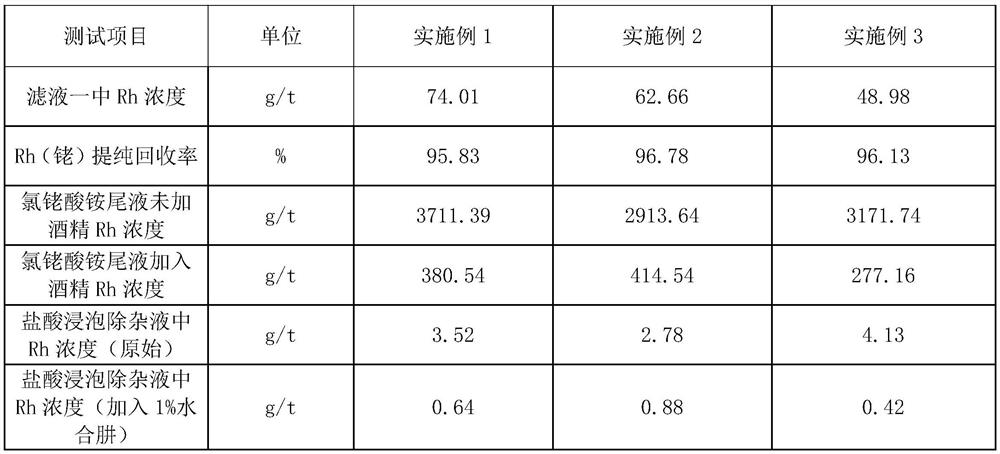

Embodiment 1

[0029] A method for separating and purifying rhodium in an impurity-containing rhodium solution, comprising the following processing steps:

[0030] S1 Adjust the acidity of the rhodium solution to 6mol / L, the heating temperature is 60-80°C, the rhodium concentration is 5-8g / L, slowly add the prepared DETA solution while stirring, the amount added is 8 times the amount of rhodium in the solution, and A large amount of red precipitate was cooled, filtered and washed to obtain filtrate 1; reduced iron powder was added to filtrate 1 in S1 to replace rhodium ions in the filtrate. In S1, because a large number of metal impurity ions remain in the solution, zinc powder is not used for replacement, and reduced iron powder is selected to replace rhodium ions in filtrate 1, so as to avoid the replacement of impurity metals into the replacement slag. Among them, the prepared DETA solution is composed of 1.13Kg of deionized water, 3.56Kg of analytically pure hydrochloric acid, and 1Kg of...

Embodiment 2

[0037] A method for separating and purifying rhodium in an impurity-containing rhodium solution, comprising the following processing steps:

[0038] S1 Adjust the acidity of the rhodium solution to 7mol / L, the heating temperature is 60-80°C, the rhodium concentration is 5-8g / L, slowly add the prepared DETA solution while stirring, the amount added is 9 times the amount of rhodium in the solution, and A large amount of red precipitate was cooled, filtered and washed to obtain filtrate 1; reduced iron powder was added to filtrate 1 in S1 to replace rhodium ions in the filtrate. In S1, because a large number of metal impurity ions remain in the solution, zinc powder is not used for replacement, and reduced iron powder is selected to replace rhodium ions in filtrate 1, so as to avoid the replacement of impurity metals into the replacement slag. Among them, the prepared DETA solution is composed of 1.13Kg of deionized water, 3.56Kg of analytically pure hydrochloric acid, and 1Kg of...

Embodiment 3

[0045] A method for separating and purifying rhodium in an impurity-containing rhodium solution, comprising the following processing steps:

[0046] S1 Adjust the acidity of the rhodium solution to 8mol / L, the heating temperature is 60-80°C, the rhodium concentration is 5-8g / L, slowly add the prepared DETA solution while stirring, the amount added is 10 times the amount of rhodium in the solution, and A large amount of red precipitate was cooled, filtered and washed to obtain filtrate 1; reduced iron powder was added to filtrate 1 in S1 to replace rhodium ions in the filtrate. In S1, because a large number of metal impurity ions remain in the solution, zinc powder is not used for replacement, and reduced iron powder is selected to replace rhodium ions in filtrate 1, so as to avoid the replacement of impurity metals into the replacement slag. Among them, the prepared DETA solution is composed of 1.13Kg of deionized water, 3.56Kg of analytically pure hydrochloric acid, and 1Kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com