Method for recovering gold by using adsorption resin

An adsorption resin and gold recovery technology, which is applied in the field of hydrometallurgy, can solve the problems of unfavorable environmental protection and general adsorption capacity, and achieve the effects of simple operation, efficient selective recovery, excellent selectivity and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

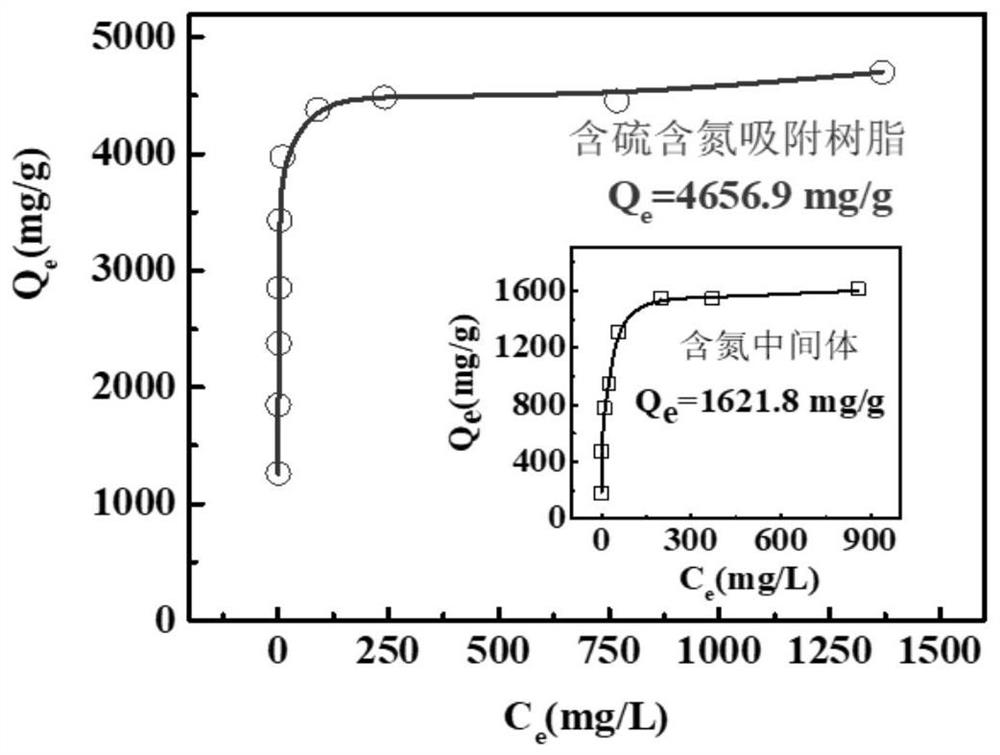

[0057] Example 1 Nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption resin (the total content of nitrogen and sulfur is 37.4%) to the adsorption isotherm test of high-concentration gold

[0058] Weigh 0.01 g of the adsorption resin and put it into 10 mL of aqueous solution containing Au(III) at 35°C for static Batch adsorption experiment. The Au(III) solution in the adsorption experiment was prepared with chloroauric acid. After adsorption at natural pH for a period of time, the supernatant was filtered out with a filter head, and the residual concentration of Au(III) was detected by ICP-OES and its adsorption amount (Q e ).

[0059] The adsorption isotherm of nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption resin (the total content of nitrogen and sulfur is 37.4%) to gold is as follows: figure 1 shown. It can be concluded from the figure that compared with the nitrogen-containing intermediate, the sulfu...

Embodiment 2

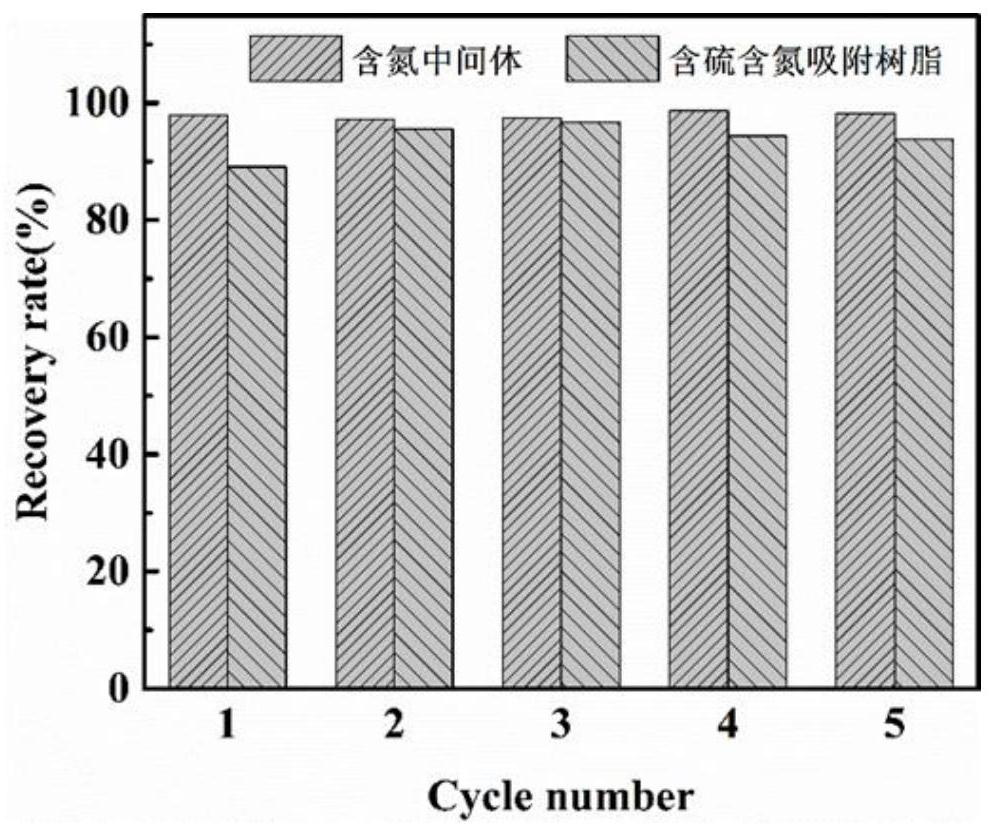

[0062] Example 2 Nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption resin (the total content of nitrogen and sulfur is 37.4%) to the repeated utilization experiment of high-concentration gold

[0063] Weigh 0.01 g of the adsorption resin, and put it into 10 mL of an aqueous solution containing Au(III) at 35°C. After adsorption at natural pH for a period of time, the supernatant was filtered out with a filter head, and the residual concentration of Au(III) was detected by AAS and the recovery rate was calculated. The gold-loaded resin was washed three times with deionized water, and 1mol / L HCl, 0.25mol / L thiourea and 0.5% H were added thereto. 2 o 2Blend the eluents for elution. For each adsorption experiment, the resin was washed three times with deionized water, and then the next cycle was performed. Repeat this five times.

[0064] Nitrogen-containing intermediates and sulfur-containing nitrogen-containing adsorption resin (the total co...

Embodiment 3

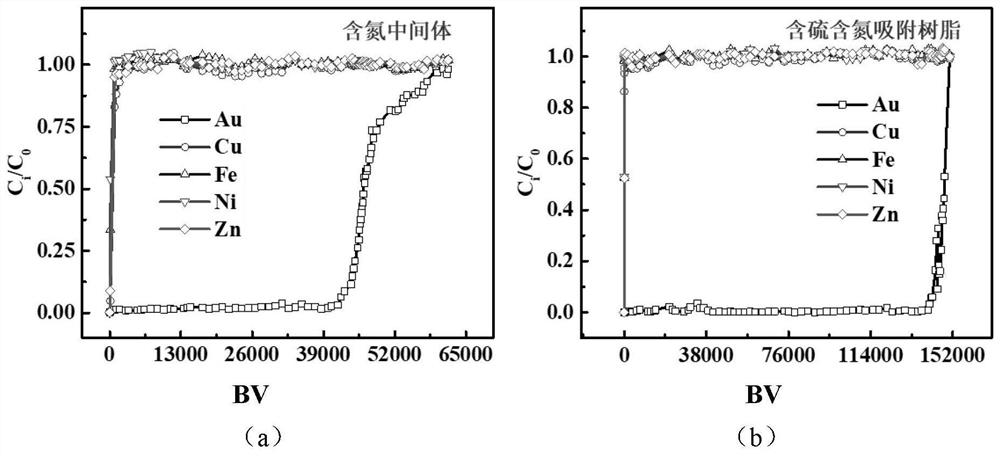

[0065] Example 3 Dynamic adsorption experiment of nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption resin (the total content of nitrogen and sulfur is 37.4%) recovering gold from simulated wastewater

[0066] Fill the resin into the adsorption column in a wet state. The dynamic adsorption evaluation conditions: the volume of the adsorption column is 3mL, the amount of filled nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption resin is 2.4777g and 2.6644g respectively, Au(III), Cu (II), Fe(III), Zn(II)Ni(II) concentration is 0.1mmol / L, flow rate is 1.5mL / min (SV=30h -1 ).

[0067] According to the above experimental conditions, the dynamic adsorption experiment evaluation was carried out, and through sampling and analysis at specific time intervals, it was obtained image 3 the penetration curve. The results show that the nitrogen-containing intermediate and sulfur-containing nitrogen-containing adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com