Spicy beef slice and preparation method thereof

A technology of beef slices and spicy, which is applied in the direction of freezing/cooling preservation of meat/fish, food freezing, food ingredients as antioxidants, etc. It can solve the problems of repeated thawing of products, darkening of meat slices, and deterioration of taste, etc. Uniformity, low juice loss, good tenderization and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] A kind of spicy beef slices, comprising the following raw materials in mass percentages:

[0103] 61% of beef slices, 3.6% of seasoning, 1.5% of marinade, 0.7% of capsicum (Vitexia officinalis), 0.85% of pigment solution, 3.7% of red oil, the balance is water, and the sum of the total mass percentage is 100% (It can be regarded as 100kg).

[0104] The seasoning is edible salt, chicken essence, (grade one) green pepper powder, (two vitex) pepper powder, spicy beef cured powder, beef powder seasoning, Sichuan pepper powder and thirteen spices, and its mass ratio is 0.01:0.31:0.12 :0.25:1.85:0.86:0.12:0.12.

[0105] Spicy beef cured powder is made by mixing chili, monosodium glutamate and spices, and its mass ratio is 1.2:0.46:0.50:2.

[0106] The pickle powder seasoning is made by mixing sodium bicarbonate, sodium carbonate and edible salt, and its mass ratio is 1:1:0.5.

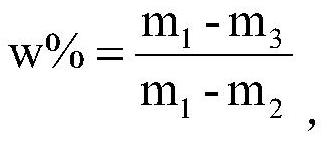

[0107] The marinade is compound water retention antioxidant, baking soda, compound water retentio...

Embodiment 2

[0132] A kind of spicy beef slices, comprising the following raw materials in mass percentages:

[0133] 62% of beef slices, 3.8% of seasoning, 1.6% of marinade, 0.9% of capsicum (Vitexia vitex), 0.9% of pigment solution, 3.8% of red oil, the balance is water, and the sum of the total mass percentage is 100% .

[0134] All the other conditions are consistent with Example 1.

Embodiment 3

[0136] The invention discloses a sliced beef, which only slices the beef directly according to the specific implementation method, and directly performs quick-freezing, boxing, and storage.

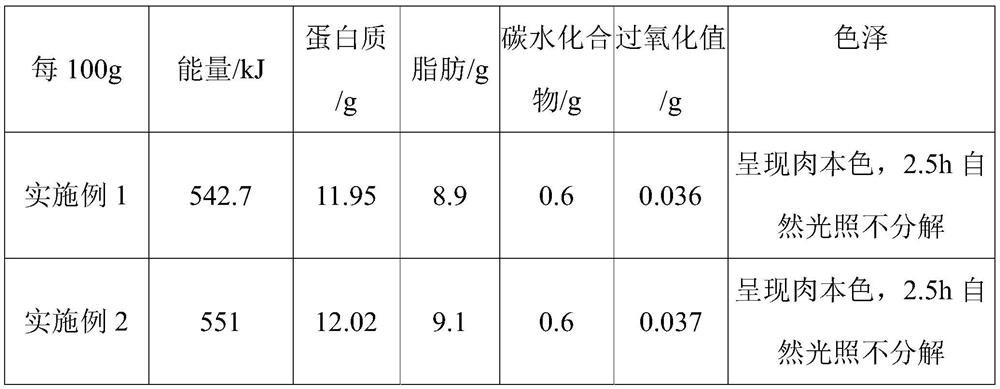

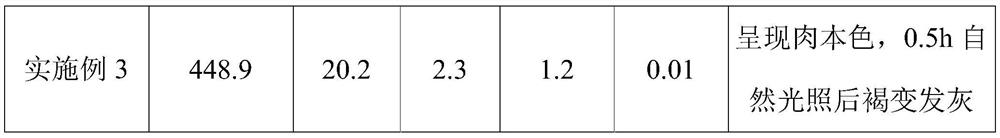

[0137] The beef slices prepared in Example 1-3 are detected, and the specific results are as follows:

[0138]

[0139]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com