A kind of preparation method of nanoporous carbon ceramic membrane nanofiltration composite membrane

A nanoporous carbon and ceramic membrane technology, applied in the field of ceramic membranes, can solve problems such as complex procedures, uneven pore size distribution, and limited application range, and achieve the effect of simple preparation process, easy promotion, and enhanced hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of boehmite sol: under nitrogen protection, 0.05 mol of aluminum sec-butoxide was added dropwise to 7 mol of deionized water with stirring, and the reaction temperature was kept at 80 °C to avoid the formation of aluminum hydroxide, The solution was kept at 90 °C for 1 h to remove the generated butanol, then the solution was cooled to 60 °C and 1 mol / L nitric acid solution was added to adjust the pH to 2.5. The resulting colloidal solution was refluxed at 90 °C for 20 h to obtain a boehmite sol solution.

[0038] (2) Preparation of sol-gel solution: Mix tetraethoxysilane (TEOS), water and ethanol in a molar ratio of 1:8.2:6.75 in a 250ml beaker, and adjust the solution with HCl with a concentration of 1mol / L pH to 2, magnetic stirring for 60 min; 8.543 g of CTAB was added, the mass fraction (wt%) of CTAB in the solution was 9.3, and a sol-gel solution was obtained after magnetic stirring for 120 min.

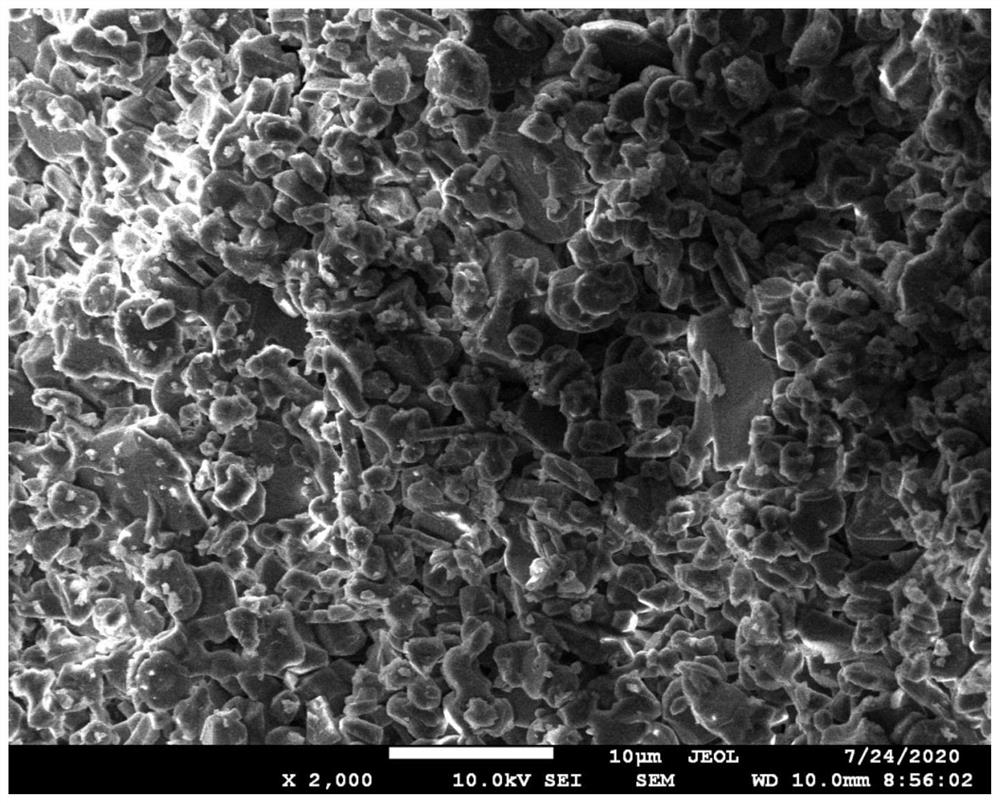

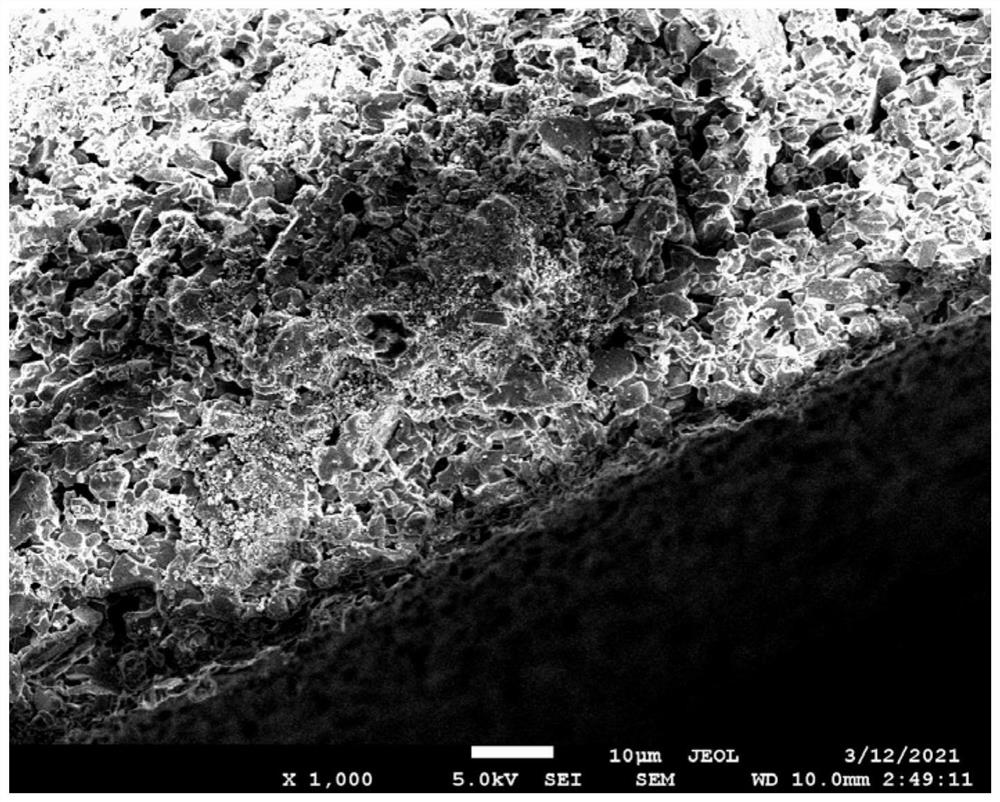

[0039] (3) Single-channel tubular Al with a pore si...

Embodiment 2

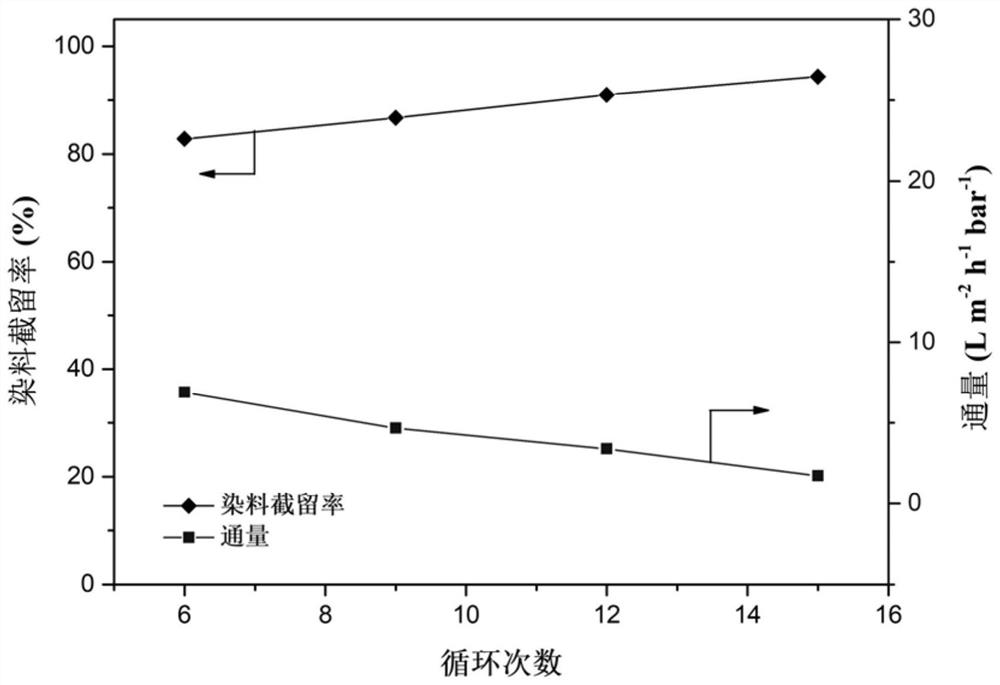

[0043] As in Example 1, the difference is that the number of MOF growth cycles is 6-15, and step (5) is not performed. The effect of cycle times on the rejection performance of ZIF-67 ceramic membrane nanofiltration composite membrane was investigated. With the increase of the number of cycles, the dye rejection rate of the composite membrane increased continuously, and the flux decreased accordingly. When the number of cycles reaches more than 12 times, the retention rate is more than 90%. It can be speculated that the continuous increase of the number of cycles leads to the gradual reduction of the inner space of the membrane pore channel, the pores in the membrane are gradually filled with MOF crystals, and the volume of macropores and mesopores is gradually reduced. decreases, the micropore volume increases, and then the dye retention rate is higher, and the flux gradually decreases. like image 3 As shown, when the number of cycles reaches 15, the retention rate of Cong...

Embodiment 3

[0045] As in Example 1, the difference lies in the fact that the precursor reaction solution Co(NO 3 ) 2 ·6H 2 The O concentration was 0.025-0.05 mol / L, and step (5) was not carried out. The effect of the concentration of precursor reaction solution on the rejection performance of ZIF-67 ceramic membrane nanofiltration composite membrane was investigated. Due to the regular shape and small size of ZIF-67 crystals formed by crystallization of low-concentration precursor solution, the probability of crystal growth in mesopores is greater, the film formation is more dense, and the flux is relatively low. With the increase of the concentration, the generated crystal particles are larger, and it is difficult to crystallize in the mesopores, resulting in the decrease of the retention performance of the composite membrane. like Figure 4 shown, Co(NO) with a concentration of 0.05 mol / L 3 ) 2 ·6H 2 The dye rejection rate of O ethanol solution was the highest, reaching 96.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com