Titanium dioxide-carbon nanotube flexible composite film as well as preparation method and application thereof

A technology of titanium dioxide and carbon nanotubes, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as weak hydrophilicity, achieve easy recycling, increase contact area, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

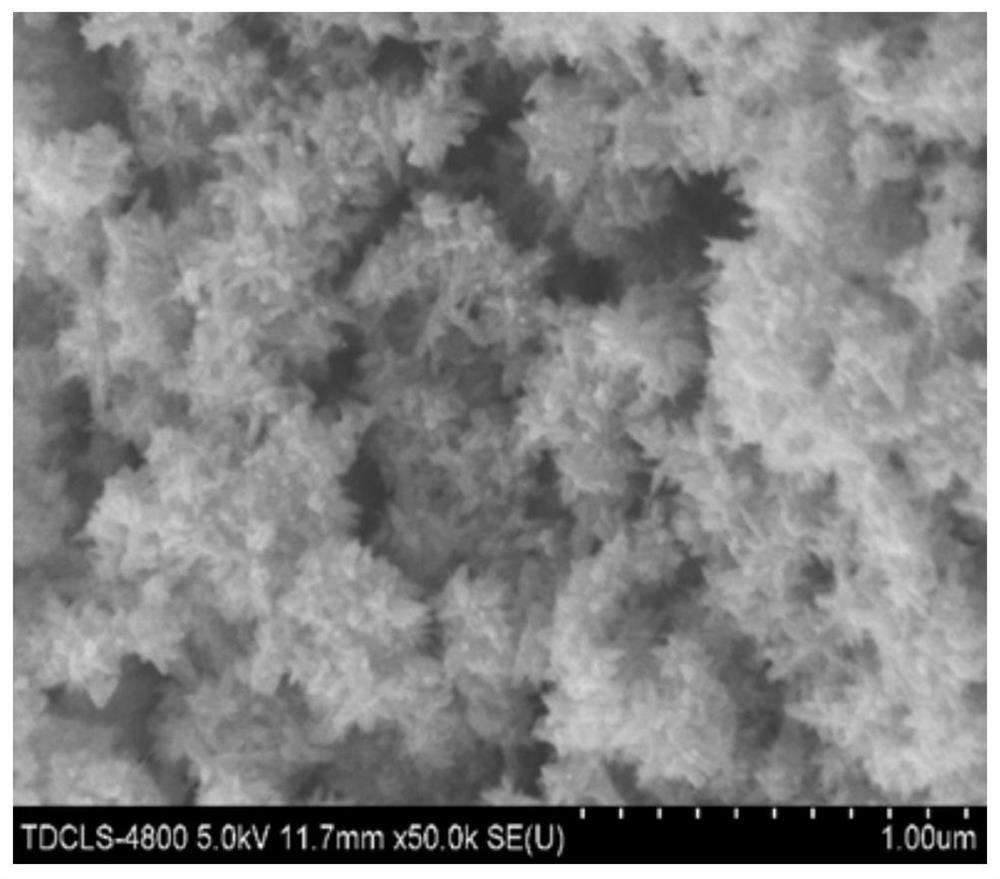

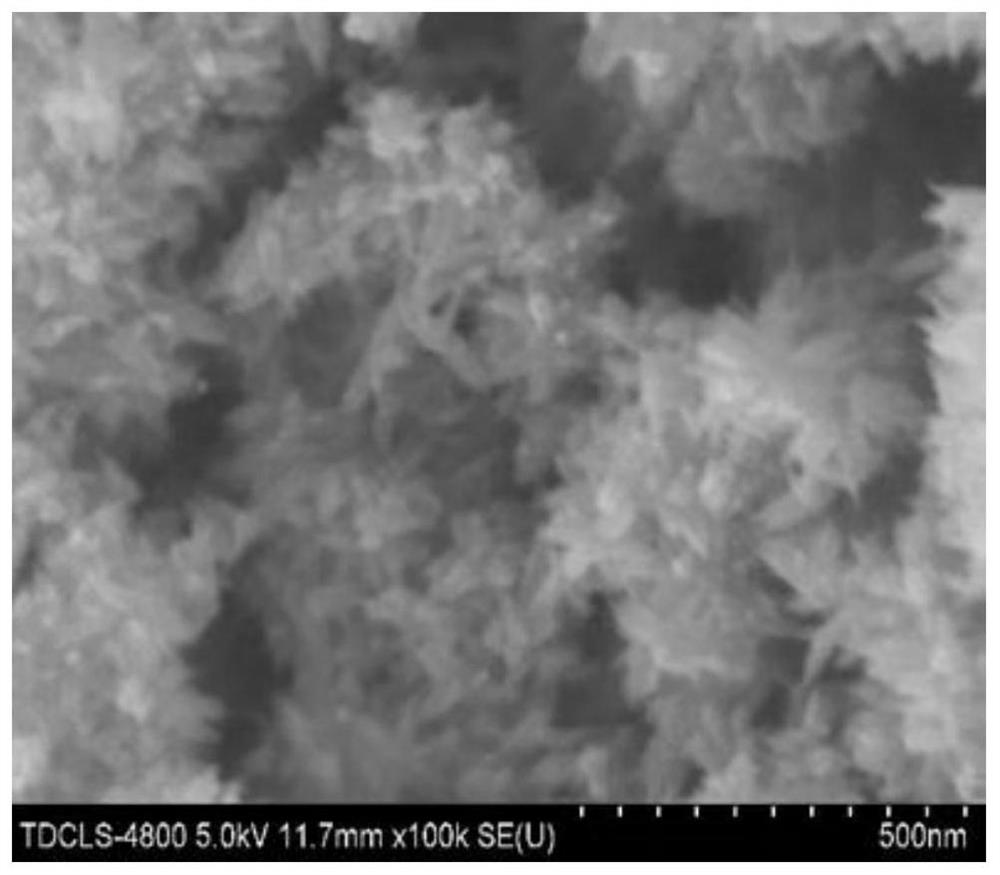

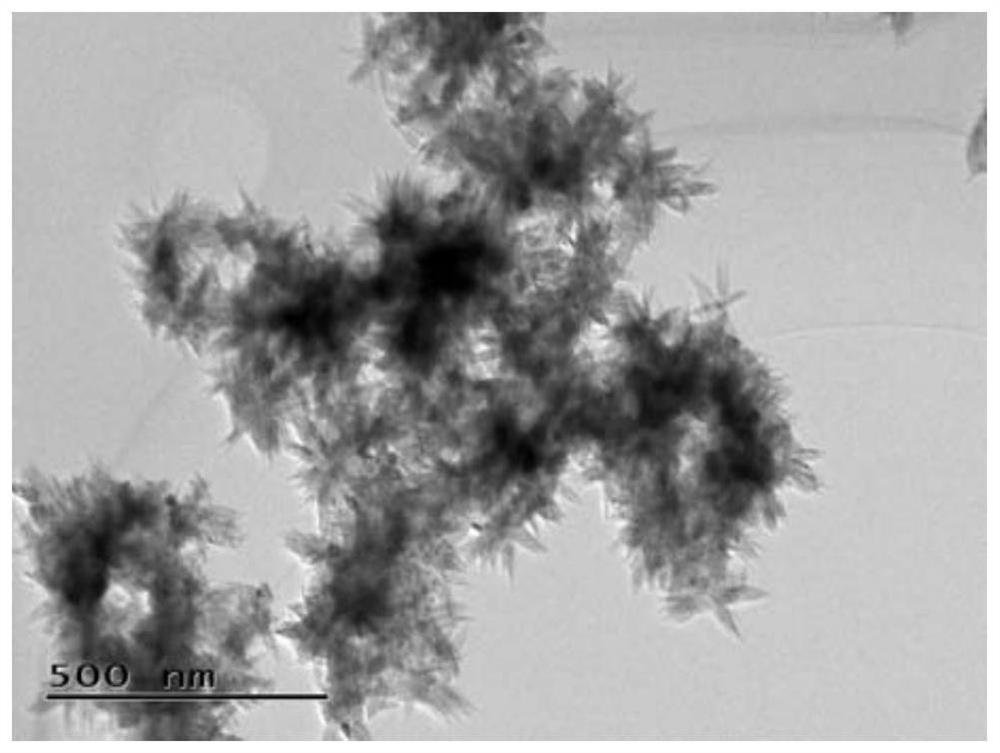

Image

Examples

Embodiment 1

[0040] Weigh 1.008g deionized water, 0.072g GR high-purity absolute ethanol, 0.0036g titanium tetrachloride, and 0.02g pure carbon tube film. Among them, titanium tetrachloride is used as the titanium source of this reaction, the carbon tube film is used as the carbon source, and absolute ethanol is used for the alcoholysis.

[0041] A method for preparing titanium dioxide-carbon nanotube flexible composite film, comprising the following steps:

[0042] (1) Add GR high-purity absolute ethanol to a dry beaker, add carbon tube film, and start magnetic stirring; add titanium tetrachloride solution drop by drop, and continue stirring for 10 minutes after the drop;

[0043] (2) After the solution is transparent, first use clean tweezers to transfer the carbon tube film to a beaker filled with deionized water, turn on magnetic stirring, and transfer the solution to a beaker filled with deionized water, the transfer method is drop by drop Add, dropwise time is 30min; After the solut...

Embodiment 2

[0048] Weigh 1.008g deionized water, 0.072g GR high-purity absolute ethanol, 0.0036g titanium tetrachloride, and 0.05g pure carbon tube film. Among them, titanium tetrachloride is used as the titanium source of this reaction, the carbon tube film is used as the carbon source, and absolute ethanol is used for the alcoholysis.

[0049] A method for preparing titanium dioxide-carbon nanotube flexible composite film, comprising the following steps:

[0050] (1) Add GR high-purity absolute ethanol to a dry beaker, add carbon tube film, and start magnetic stirring; add titanium tetrachloride solution drop by drop, and continue stirring for 15 minutes after the drop;

[0051] (2) After the solution is transparent, first use clean tweezers to transfer the carbon tube film to a beaker filled with deionized water, turn on magnetic stirring, and transfer the solution to a beaker filled with deionized water, the transfer method is drop by drop Add, dropwise time is 35min; After the solut...

Embodiment 3

[0055] Weigh 1.008g deionized water, 0.072g GR high-purity absolute ethanol, 0.0036g titanium tetrachloride, and 0.1g pure carbon tube film. Among them, titanium tetrachloride is used as the titanium source of this reaction, the carbon tube film is used as the carbon source, and absolute ethanol is used for the alcoholysis.

[0056] A method for preparing titanium dioxide-carbon nanotube flexible composite film, comprising the following steps:

[0057] (1) Add GR high-purity absolute ethanol to a dry beaker, add carbon tube film, and start magnetic stirring; add titanium tetrachloride solution drop by drop, and continue stirring for 15 minutes after the drop;

[0058] (2) After the solution is transparent, first use clean tweezers to transfer the carbon tube film to a beaker filled with deionized water, turn on magnetic stirring, and transfer the solution to a beaker filled with deionized water, the transfer method is drop by drop Add, dropwise time is 40min; After the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com