Preparation method and application of sulfurized nano-iron modified composite material based on heavy metal polluted wastewater remediation

A composite material and nano-iron technology, which is applied in the field of preparation of sulfided nano-iron modified composite materials to achieve the effects of large removal, improved reactivity and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of biochar (BC): Wash and dry the cattails, grind and sieve, weigh 10g cattails in a crucible, add 50% H 3 PO 4 The solution was stirred evenly and left to stand for 24 hours, then placed in a muffle furnace for anaerobic calcination at 469.5°C for 90 minutes, then immersed in a 10% HCl solution for 30 minutes, vacuum filtered, dried, ground and sieved, and stored for later use.

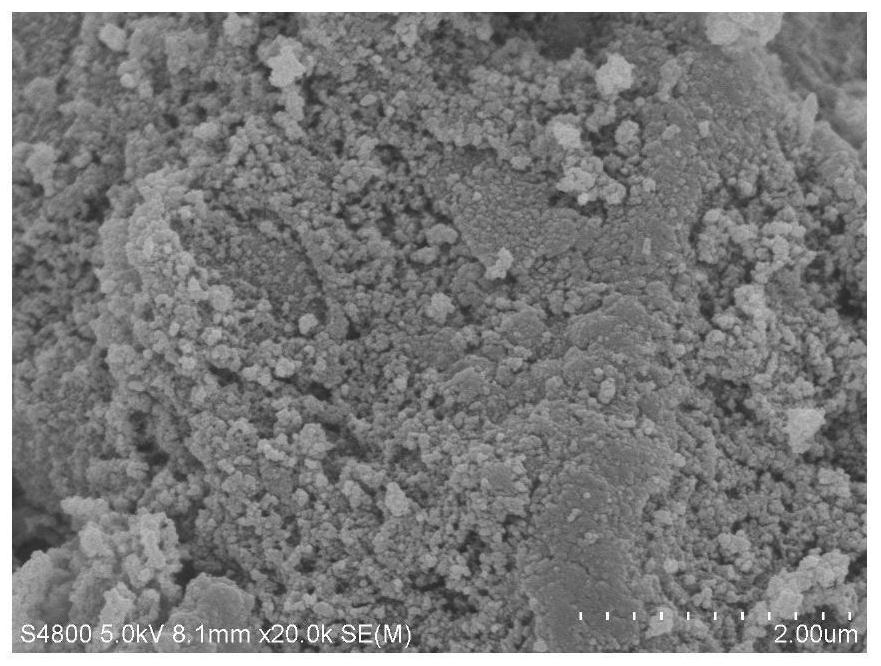

[0018] The scanning electron microscope figure of BC in the present embodiment 1 is as figure 1 As shown, the surface is rough and uneven.

Embodiment 2

[0020] Preparation of sulfide nano-iron (S-nZVI): add 0.075M FeSO to the three-necked flask after passing through nitrogen to remove oxygen 4 solution, and then add 200mL of 0.20M NaBH dropwise with a peristaltic pump 4 and an appropriate amount of Na 2 After the S (S / Fe molar ratio is 0.56) mixed solution was added dropwise, it was fully stirred for 30 minutes, and the obtained black particles were collected by a magnet, washed with ultrapure water and absolute ethanol several times, centrifuged, and vacuum-dried for storage.

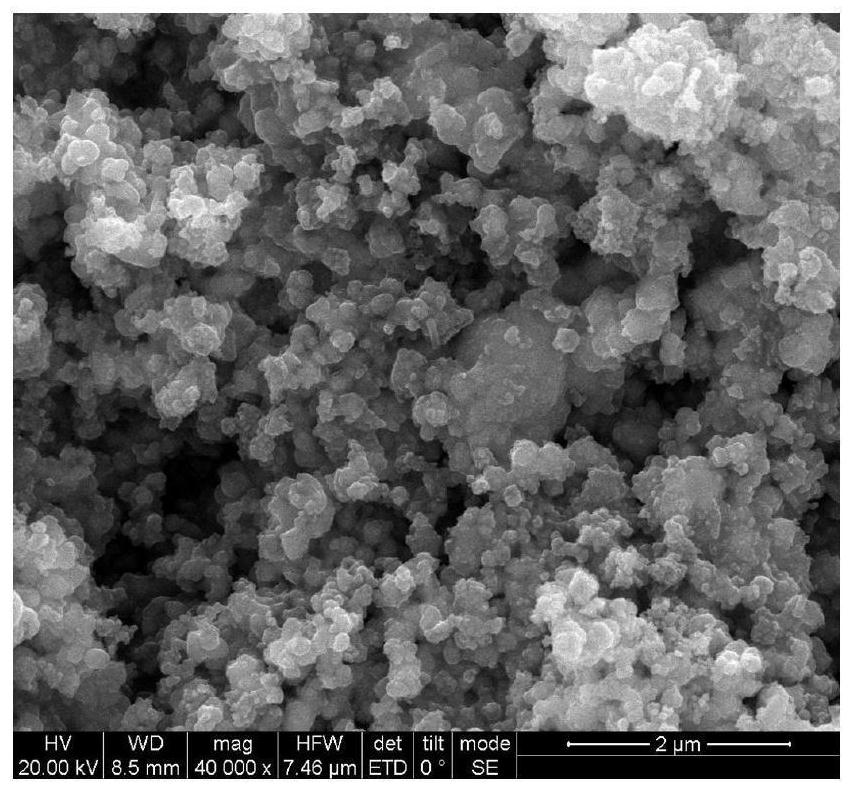

[0021] The scanning electron microscope figure of S-nZVI in the present embodiment 2 is as figure 2 As shown, the S-nZVI particles aggregated together in a spherical shape.

Embodiment 3

[0023] Preparation of biochar-supported sulfide nano-iron (S-nZVI / BC): add 0.075M FeSO 4 solution and 1g of BC, stir evenly, then add 200mL of 0.20M NaBH dropwise with a peristaltic pump 4 and an appropriate amount of Na 2 After the S (S / Fe molar ratio is 0.56) mixed solution was added dropwise, it was fully stirred for 30 minutes, and the obtained black particles were collected by a magnet, washed with ultrapure water and absolute ethanol several times, centrifuged, and vacuum-dried for storage.

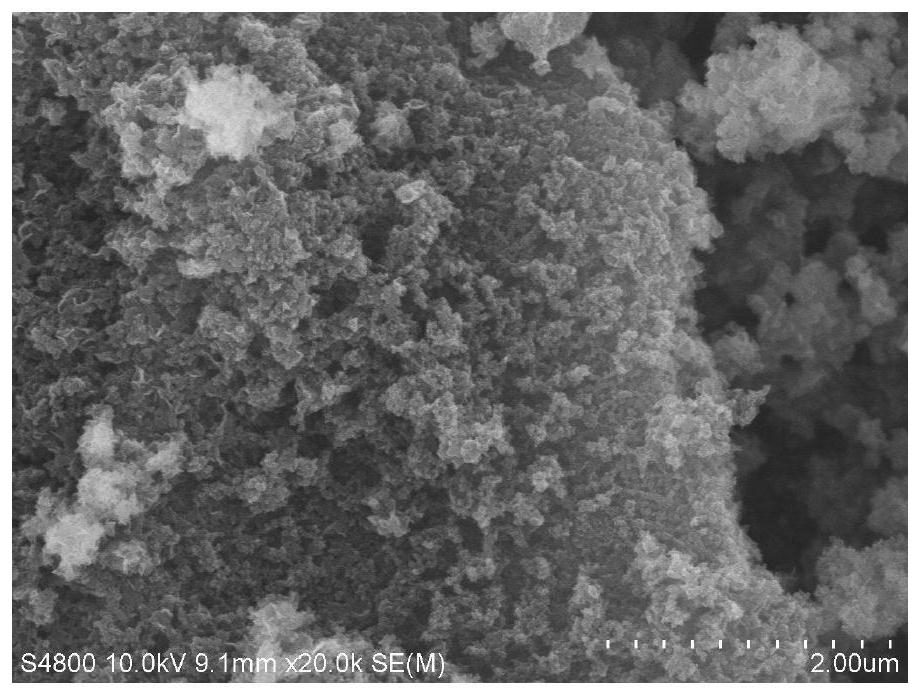

[0024] The scanning electron microscope picture of S-nZVI / BC in the present embodiment 3 is as follows image 3 As shown, the S-nZVI particles were dispersed on the surface of BC as small particles, but the distribution was not uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com