Special waterproof anti-corrosion high polymer spraying material for concrete and preparation method of special waterproof anti-corrosion high polymer spraying material

A polymer and concrete technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of weak aging resistance, coating damage, poor water resistance, etc., achieve good protection effect, improve compactness and strength, comprehensive effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

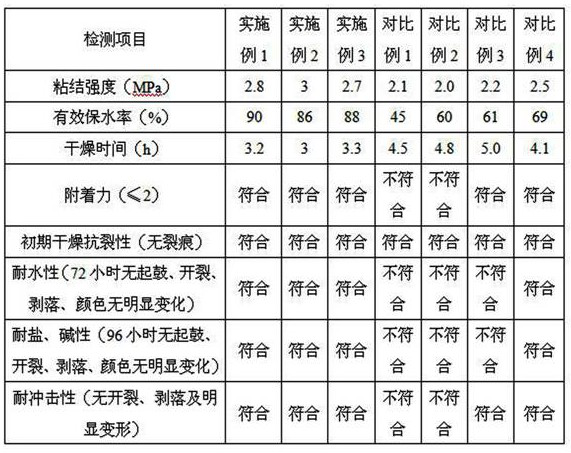

Embodiment 1

[0031] Add 5.1 parts of polyacrylamide, 23.2 parts of tris(hydroxymethyl)nitromethane, 18 parts of sodium nitrite, 5 parts of ammonium dihydrogen phosphate, 7 parts of magnesium oxide powder, and 2 parts of borax into the mixing drum of the mixer, Stir at a constant speed for 5-10 minutes until the three base materials are evenly stirred. Add 11.0 parts of ionic water into the mixing drum, slowly, and keep stirring for 5-10 minutes after all the water is added. Add 5.2 parts of defoamer and 9.7 parts of natural cotton fiber into the mixing drum in turn, and continue stirring at a constant speed for 5 to 10 minutes. Continuously stir 42.5 parts of stone powder, 19.4 parts of silicone acrylic, 7.4 parts of acrylic acid, and 8.8 parts of BA-510TS flexible emulsion at a constant speed for 5 to 10 minutes. Finally, add 2.5 parts of waterproofing agent. The bonding strength is 2.8MPa, the effective water retention rate is 90%, and the drying time is 3.2h.

Embodiment 2

[0033] Add 7.2 parts of polyacrylamide, 23.2 parts of tris(hydroxymethyl)nitromethane, 18 parts of sodium nitrite, 5 parts of ammonium dihydrogen phosphate, 7 parts of magnesium oxide powder, and 2 parts of borax into the mixing drum of the mixer, Stir at a constant speed for 5-10 minutes until the three base materials are evenly stirred. Add 11.0 parts of ionic water into the mixing drum, slowly, and keep stirring for 5-10 minutes after all the water is added. Add 5.2 parts of defoamer and 11.1 parts of natural cotton fiber into the mixing drum in turn, and continue stirring at a constant speed for 5 to 10 minutes. Continue to stir 37.3 parts of stone powder, 19.4 parts of silicone acrylic, 7.4 parts of acrylic acid, and 8.8 parts of BA-510TS flexible emulsion at a constant speed for 5 to 10 minutes. Finally, add 2.5 parts of waterproofing agent. The bonding strength is 3MPa, the effective water retention rate is 86%, and the drying time is 3h.

Embodiment 3

[0035] Add 8.6 parts of polyacrylamide, 23.2 parts of tris(hydroxymethyl)nitromethane, 18 parts of sodium nitrite, 5 parts of ammonium dihydrogen phosphate, 7 parts of magnesium oxide powder, and 2 parts of borax into the mixing drum of the mixer. Stir at a constant speed for 5-10 minutes until the three base materials are evenly stirred. Add 11.0 parts of ionic water into the mixing drum, slowly, and keep stirring for 5-10 minutes after all the water is added. Add 5.2 parts of defoamer and 12.6 parts of natural cotton fiber into the mixing drum in turn, and continue stirring at a constant speed for 5 to 10 minutes. Continue to stir 33.8 parts of stone powder, 19.4 parts of silicon acrylic, 7.4 parts of acrylic acid, and 8.8 parts of BA-510TS flexible emulsion at a constant speed for 5 to 10 minutes. Finally, add 2.5 parts of waterproofing agent. The bonding strength is 2.7MPa, the effective water retention rate is 88%, and the drying time is 3.3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com