Photo-thermal enhanced supercapacitor electrode material and preparation method thereof

A supercapacitor and electrode material technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, copper sulfide, etc., can solve the problems of poor flexibility and stability of electrodes, capacity decay of supercapacitors, and easy falling off of active materials. Accelerate the kinetic process, improve the electrochemical performance, and increase the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

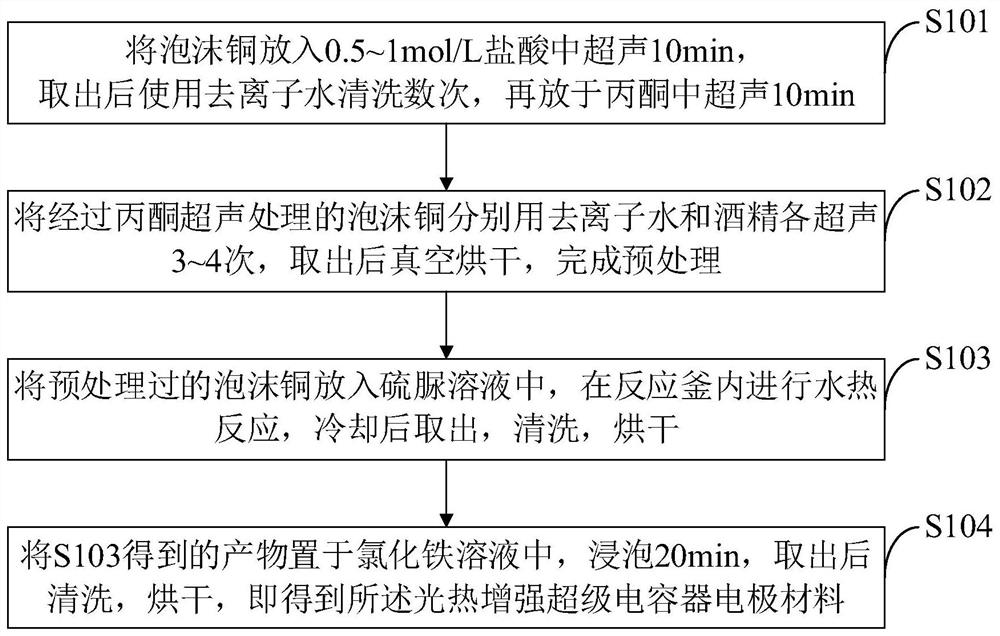

[0034] Such as figure 1 As shown, the preparation method of the photothermally enhanced supercapacitor electrode material provided by the embodiment of the present invention includes the following steps:

[0035] S101, put copper foam into 0.5-1mol / L hydrochloric acid and sonicate for 10 minutes, take it out and wash it several times with deionized water, then put it in acetone and sonicate for 10 minutes;

[0036] S102, ultrasonically ultrasonicate the copper foam treated with acetone for 3 to 4 times with deionized water and alcohol respectively, take it out, and vacuum dry it to complete the pretreatment;

[0037] S103, putting the pretreated foamed copper into the thiourea solution, performing hydrothermal reaction in the reactor, taking it out after cooling, cleaning and drying;

[0038] S104, placing the product obtained in S103 in a ferric chloride solution, soaking it for 20 minutes, taking it out, washing it, and drying it to obtain the photothermally enhanced superc...

Embodiment 2

[0055] The preparation method of the supercapacitor electrode material with photothermal enhancement effect provided by the embodiment of the present invention comprises the following steps:

[0056] Step 1: Cut the foamed copper into 1cm*3cm, put it into 1mol / L hydrochloric acid and sonicate it for 10 minutes, take it out, wash it with deionized water for 3 times, then put it in acetone and sonicate it for 10 minutes; Sonicate 3 times with deionized water and alcohol respectively, take it out and dry it in a vacuum oven at 50°C to complete the pretreatment;

[0057] Step 2: Weigh 90 mg of thiourea and add it to a mixed solution of 15 mL of absolute ethanol and 5 mL of deionized water, stir evenly to obtain a thiourea solution; put the pretreated foamed copper into the thiourea solution, and transfer it to polytetrafluoroethylene In the vinyl fluoride stainless steel reaction kettle, hydrothermal reaction was carried out at 150°C for 6 hours. After the reaction, the reaction l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com