Method for stabilizing interface between perovskite thin film and hole transport layer

A hole transport layer and perovskite technology, applied in the field of solar cells, can solve the problems of poor stability of perovskite solar cells, instability of perovskite film and hole transport layer film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

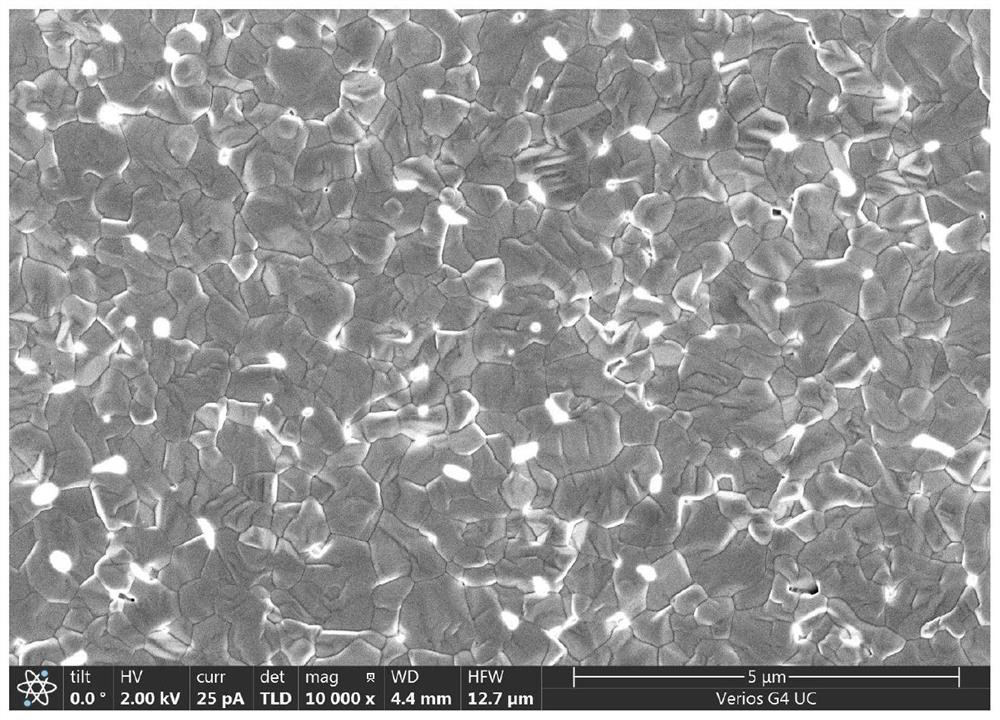

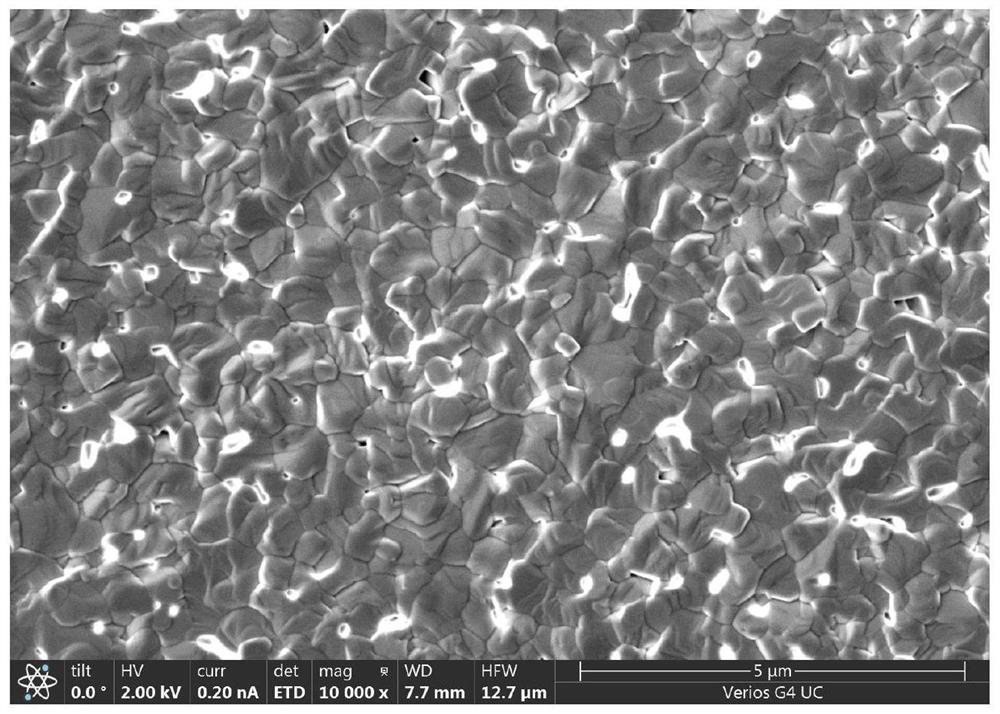

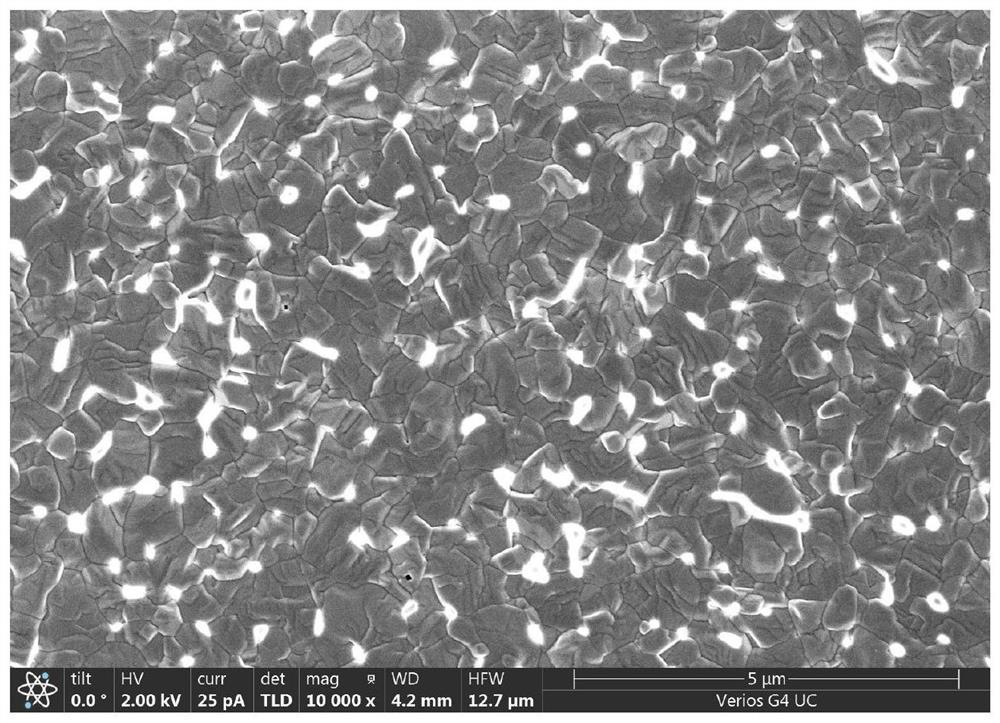

Image

Examples

preparation example Construction

[0040] A method for stabilizing the interface between a perovskite film and a hole transport layer, characterized in that: the preparation method comprises the following steps:

[0041] Step S1: ultrasonically clean the fluorine-doped tin oxide substrate with deionized water, acetone and ethanol for 30 min, and dissolve tetraisopropyl titanate in ethanol, acetylacetone and weakly acidic water solvent to prepare TiO 2 Precursor solution, place and age for 48h before use, spin-coat TiO on the cleaned fluorine-doped tin oxide substrate at 3000rpm 2 Precursor solution for 20s, after spin coating, sintering in a muffle furnace at 510°C for 30min.

[0042] Step S2: Step S2 includes the following steps,

[0043] S21: Prepare 1,4-dibromobenzene precursor solution, the solute of 1,4-dibromobenzene precursor solution is 1,4-dibromobenzene powder, the solvent is isopropanol, and the concentration of the prepared solution is 0.2-2mg / ml.

[0044] S22: configure CH 3 NH 3 PB 3 Precur...

Embodiment 1

[0051] A method for stabilizing the interface between a perovskite film and a hole transport layer, the preparation method comprising the following steps:

[0052] Step S1: ultrasonically clean the fluorine-doped tin oxide substrate with deionized water, acetone and ethanol for 30 min, and dissolve tetraisopropyl titanate in ethanol, acetylacetone and weakly acidic water solvent to prepare TiO 2 Precursor solution, place and age for 48h before use, spin-coat TiO on the cleaned fluorine-doped tin oxide substrate at 3000rpm 2 Precursor solution for 20s, after spin coating, sintering in a muffle furnace at 510°C for 30min.

[0053] Step S2: Step S2 includes the following steps,

[0054] S21: Prepare 1,4-dibromobenzene precursor solution, the solute of 1,4-dibromobenzene precursor solution is 1,4-dibromobenzene powder, the solvent is isopropanol, and the concentration of the prepared solution is 0.2mg / ml.

[0055] S22: configure CH 3 NH 3 PB 3 Precursor solution, CH 3 NH ...

Embodiment 2

[0064] A method for stabilizing the interface between a perovskite film and a hole transport layer, the preparation method comprising the following steps:

[0065] Step S1: ultrasonically clean the fluorine-doped tin oxide substrate with deionized water, acetone and ethanol for 30 min, and dissolve tetraisopropyl titanate in ethanol, acetylacetone and weakly acidic water solvent to prepare TiO 2 Precursor solution, place and age for 48h before use, spin-coat TiO on the cleaned fluorine-doped tin oxide substrate at 3000rpm 2 Precursor solution for 20s, after spin coating, sintering in a muffle furnace at 510°C for 30min.

[0066] Step S2: Step S2 includes the following steps,

[0067] S21: Prepare 1,4-dibromobenzene precursor solution, the solute of 1,4-dibromobenzene precursor solution is 1,4-dibromobenzene powder, the solvent is isopropanol, and the concentration of the prepared solution is 0.6mg / ml.

[0068] S22: configure CH 3 NH 3 PB 3 Precursor solution, CH 3 NH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com