Polyolefin pipe easy to repair quickly, and repair process method thereof

A process method and polyolefin technology, applied in the field of quick and easy repair polyolefin pipes and their repair technology, can solve the problems of shortened pipe life, difficulty in fitting the lining material of the main pipe, etc., to facilitate transportation and installation, improve the effect of surface interface, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

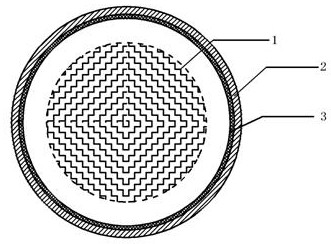

[0029]The repairing process method of easy-to-repair, quick and easy-to-repair polypropylene pipes includes the following steps: S1. Preparatory work: use a pipeline stop valve to cut off the fluid transported by the fast and easy-to-repair polypropylene pipes that need to be repaired, and clean them up; S2. Detection and positioning: Acoustic emission detection is used to quickly and easily repair the damaged part of the polypropylene pipe and locate it; S3. Wrap the glass fiber fabric impregnated with resin on the transparent inflatable airbag to obtain the wrapped fabric airbag, which is transported by the transport robot to the In the damaged part, the glass fiber fabric impregnated with resin is multi-layer wound and hollow, and there is an ultraviolet lamp irradiation robot inside the transparent air bag for repairing, and the transport robot inflates the inner cavity of the transparent repair air bag to make the glass fiber fabric expand, thereby making the The outer wal...

Embodiment 2

[0033] The inorganic filler is Jiangsu Guangyuan ultrafine talcum powder GY950, polyethylene TR480 and the wall thickness is 38.2mm; the glass fiber fabric is alkali-free glass fiber cloth, and the mass per unit area of the three layers is 1200g / m 2 , The width of the fabric is 420mm at an arrangement angle of 0°, and the multi-axial stitching fabric EUL1200 (0) EP-420E6 Taishan glass fiber with a stitch density of 6 needles / inch.

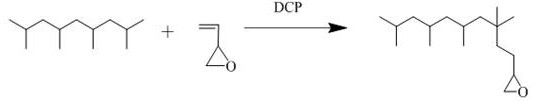

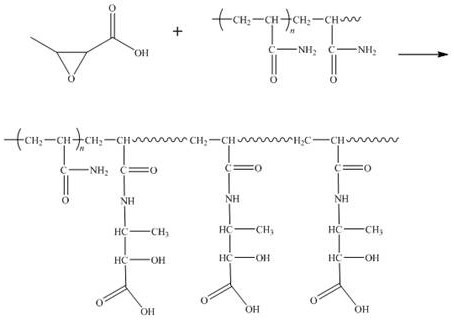

[0034] Select polyethylene resin, add 0.5% dicumyl peroxide and 10% vinyl oxirane by polyethylene mass, mix evenly, use twin-screw extruder at 180°C, extrude and granulate to obtain epoxy resin After the modified polyethylene resin, use the extrusion molding method to manufacture fast and easy-to-repair polyolefin pipes, mold forming pipe blanks, vacuum sizing sleeves for cooling and sizing, vacuum spray cooling, pipe cooling, traction, and cutting. The SJB-120 single-screw extruder is used for production and molding, and the extrusion molding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com