Dual-modified waterborne epoxy resin anticorrosive paint and preparation method thereof

A water-based epoxy resin, double modification technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problem of low anti-corrosion performance of water-based epoxy resin, enhance adhesion and mechanical properties, reduce micro Pore structure, effect of delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

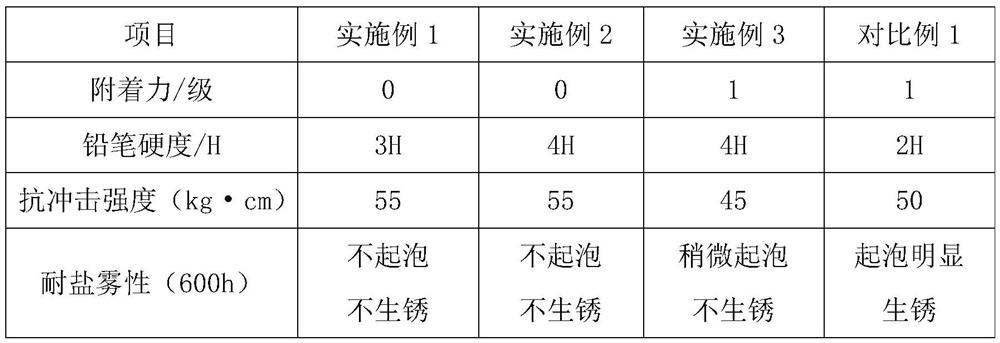

Examples

preparation example Construction

[0020] Modified SiO 2 The preparation method of supported hexagonal boron nitride comprises the following steps:

[0021] (1) Add ammonia solution, deionized water, and absolute ethanol to the reaction bottle, the volume ratio of the three is 1:2-3:5-7, put it in a water bath device, heat up to 55-65°C, and stir well Add tetraethyl orthosilicate and silane coupling agent KH550 respectively, the mass ratio of the two is 1:0.2-0.4, and continue to stir for 18-24h. After the reaction is completed, the precipitate obtained is washed by centrifugation with water and absolute ethanol to remove residual reagents, and finally the product is vacuum-dried at 60-70°C to obtain aminated nano-SiO 2 .

[0022] (2) Add deionized water and hexagonal boron nitride to the reaction bottle, and the solution is ultrasonically treated for 30-60min, and the pH value is adjusted to 8.5 with Tris-HCl buffer solution, adding dopamine, hexagonal boron nitride and dopamine The mass ratio is 1:0.2-0.3,...

Embodiment 1

[0028] (1) Preparation of aminated nano-SiO 2 Component 1: Add 9mL of ammonia solution, deionized water, and absolute ethanol to the reaction bottle, the volume ratio of the three is 1:2:5, put it in a water bath, raise the temperature to 60°C, stir well, and then add 4.5 g tetraethyl orthosilicate and silane coupling agent KH550, the mass ratio of the two is 1:0.2, continue to stir for 24h. After the reaction was completed, the obtained precipitate was centrifuged and washed with water and absolute ethanol to remove residual reagents, and finally the product was vacuum-dried at 60 °C to prepare aminated nano-SiO 2 Component 1.

[0029] (2) Preparation of polydopamine-modified hexagonal boron nitride component 1: Add 200 mL of deionized water and 2.0 g of hexagonal boron nitride into the reaction flask, ultrasonicate the solution for 60 minutes, and adjust the pH in the system with Tris-HCl buffer The value is 8.5, adding dopamine, the mass ratio of hexagonal boron nitride a...

Embodiment 2

[0033] (1) Preparation of aminated nano-SiO 2 Component 2: Add 12mL of ammonia solution, deionized water, and absolute ethanol to the reaction bottle. The volume ratio of the three is 1:2.5:6. g tetraethyl orthosilicate and silane coupling agent KH550, the mass ratio of the two is 1:0.3, continue to stir for 24h. After the reaction was completed, the obtained precipitate was centrifuged and washed with water and absolute ethanol to remove residual reagents, and finally the product was vacuum-dried at 60 °C to prepare aminated nano-SiO 2 Component 2.

[0034] (2) Preparation of polydopamine-modified hexagonal boron nitride component 2: Add 200 mL of deionized water and 2.0 g of hexagonal boron nitride to the reaction flask, ultrasonicate the solution for 60 minutes, and adjust the pH in the system with Tris-HCl buffer The value is 8.5, adding dopamine, the mass ratio of hexagonal boron nitride and dopamine is 1:0.25, stirring continuously at room temperature for 24h, centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com