High-strength corrosion-resistant stainless steel pipe fitting and machining process thereof

A processing technology, stainless steel technology, applied in the field of high-strength corrosion-resistant stainless steel pipe fittings and its processing technology, can solve the problems of not being able to meet our expectations, not durable corrosion resistance, poor service life, etc., to achieve excellent tensile strength and mechanics Effects of performance, high usability, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

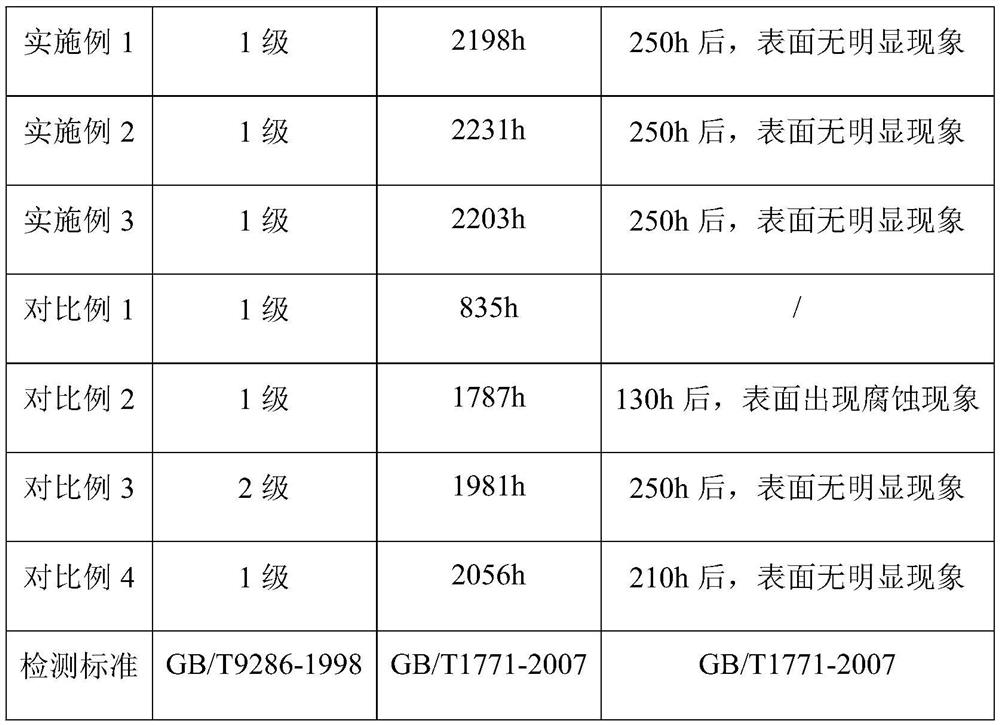

Embodiment 1

[0038] A process for processing high-strength corrosion-resistant stainless steel pipe fittings, comprising the following steps:

[0039] (1) Take stainless steel pipe fittings, polish the outer surface, place them in acetone solution for ultrasonic cleaning for 10 minutes, then place them in absolute ethanol for ultrasonic cleaning for 20 minutes, deionized water for ultrasonic cleaning for 20 minutes, and vacuum dry to obtain pretreated pipe fittings;

[0040] (2) Take the pretreatment pipe, place it in the electrolyte, use the pretreatment pipe as the anode, and use the bidirectional pulse power supply for micro-arc oxidation, the oxidation time is 60min, and the current density is 10A / dm 2 , the temperature is 25°C, the duty cycle is 20%, take out the pretreatment tube and dry it at room temperature;

[0041] (3) Take the pretreated pipe fittings, and carry out ultrasonic rolling on the outer surface, the ultrasonic amplitude is 15um, the ultrasonic frequency is 15KHz, the...

Embodiment 2

[0048] A process for processing high-strength corrosion-resistant stainless steel pipe fittings, comprising the following steps:

[0049] (1) Take stainless steel pipe fittings, polish the outer surface, place them in acetone solution for ultrasonic cleaning for 15 minutes, then place them in absolute ethanol for ultrasonic cleaning for 23 minutes, deionized water ultrasonic cleaning for 25 minutes, and vacuum dry to obtain pretreated pipe fittings;

[0050] (2) Take the pretreatment pipe, put it in the electrolyte, use the pretreatment pipe as the anode, and use the bidirectional pulse power supply for micro-arc oxidation, the oxidation time is 65min, and the current density is 15A / dm 2 , the temperature is 30°C, the duty ratio is 30%, take out the pretreatment tube and dry it at room temperature;

[0051] (3) Take the pretreated pipe fittings and perform ultrasonic rolling on the outer surface. The ultrasonic amplitude is 18um, the ultrasonic frequency is 18KHz, the spindle ...

Embodiment 3

[0058] A process for processing high-strength corrosion-resistant stainless steel pipe fittings, comprising the following steps:

[0059] (1) Take a stainless steel pipe fitting, polish the outer surface, place it in an acetone solution for ultrasonic cleaning for 20 minutes, then place it in absolute ethanol for ultrasonic cleaning for 25 minutes, ultrasonically clean it with deionized water for 30 minutes, and dry it in vacuum to obtain a pretreated pipe fitting;

[0060] (2) Take the pretreated pipe, put it in the electrolyte, use the pretreated pipe as the anode, and use the bidirectional pulse power supply for micro-arc oxidation, the oxidation time is 70min, and the current density is 20A / dm 2 , the temperature is 35°C, the duty ratio is 40%, take out the pretreatment tube and dry it at room temperature;

[0061] (3) Take the pretreated pipe fittings and perform ultrasonic rolling on the outer surface. The ultrasonic amplitude is 20um, the ultrasonic frequency is 20KHz, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com