Preparation method of FeCoNiCu series high-entropy magnetic nanopowder capable of being used for magnetic hyperthermia

A magnetic nano and magnetic hyperthermia technology, which is applied in the field of biomedical application of nanomaterials, can solve the problem that the heat production performance of the magnetic thermotherapy agent has not been well improved, and achieve a large market application potential, enhanced heat production capacity, The effect of easy operation of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The concrete of described preparation method comprises the following steps:

[0034] S1) The chloride salt raw material of Fe, Co, Ni, Cu is changed from the nominal composition Fe of alloy powder a co b Ni c Cu d Weighed after conversion into mass according to atomic percentage,

[0035] S2) The polyol solution is divided into polyol solution I and polyol solution II, and the alkaline solid particles and polyol solution I are placed in container A according to a certain ratio to obtain alkaline solid particles-polyol solution;

[0036] Put polyol solution II in container B, mix the raw materials weighed in S1) and add them to container B, put them into a magnetic rotor, stir evenly, and obtain a mixed solution,

[0037] S3) heating the mixed solution obtained, and magnetic stirring at the same time, when heated to a certain temperature, adding the alkaline solid particle-polyol solution into the mixed solution for reaction, turning off the heater after the mixed so...

Embodiment 1

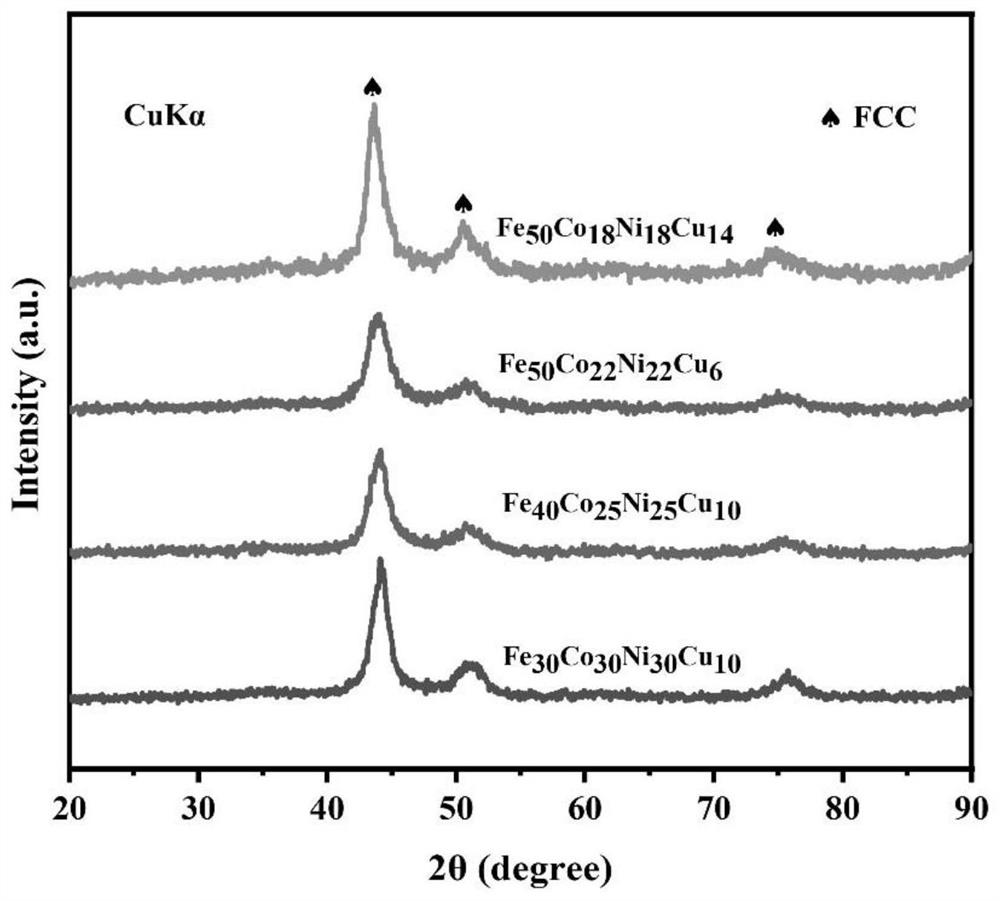

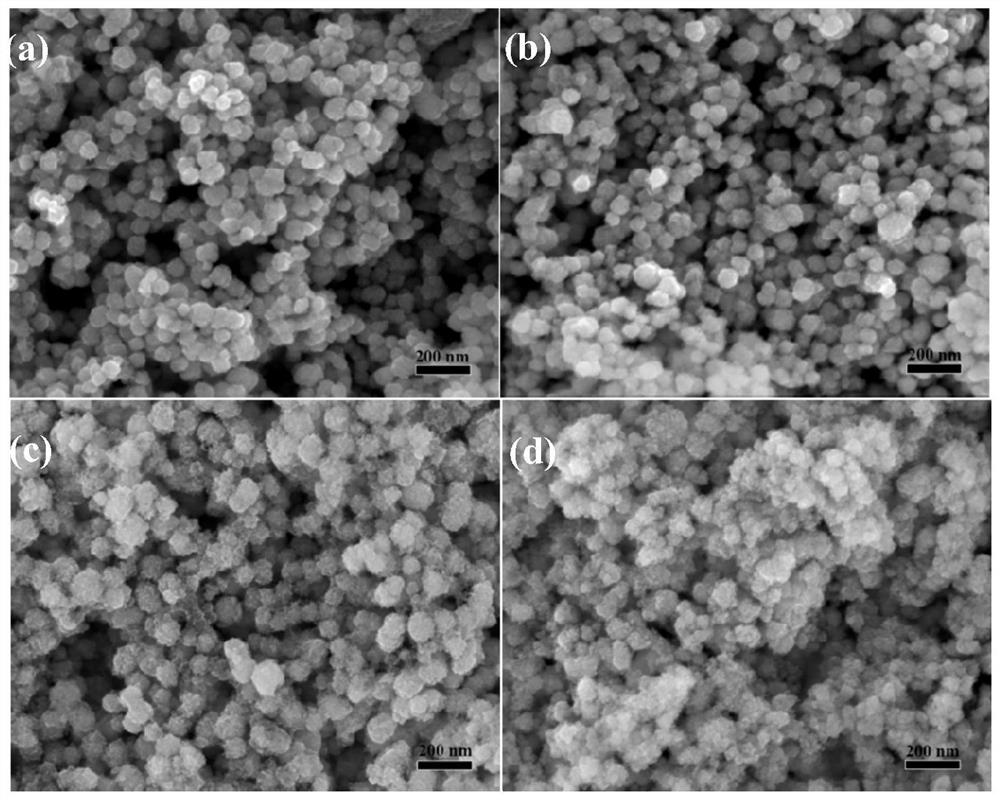

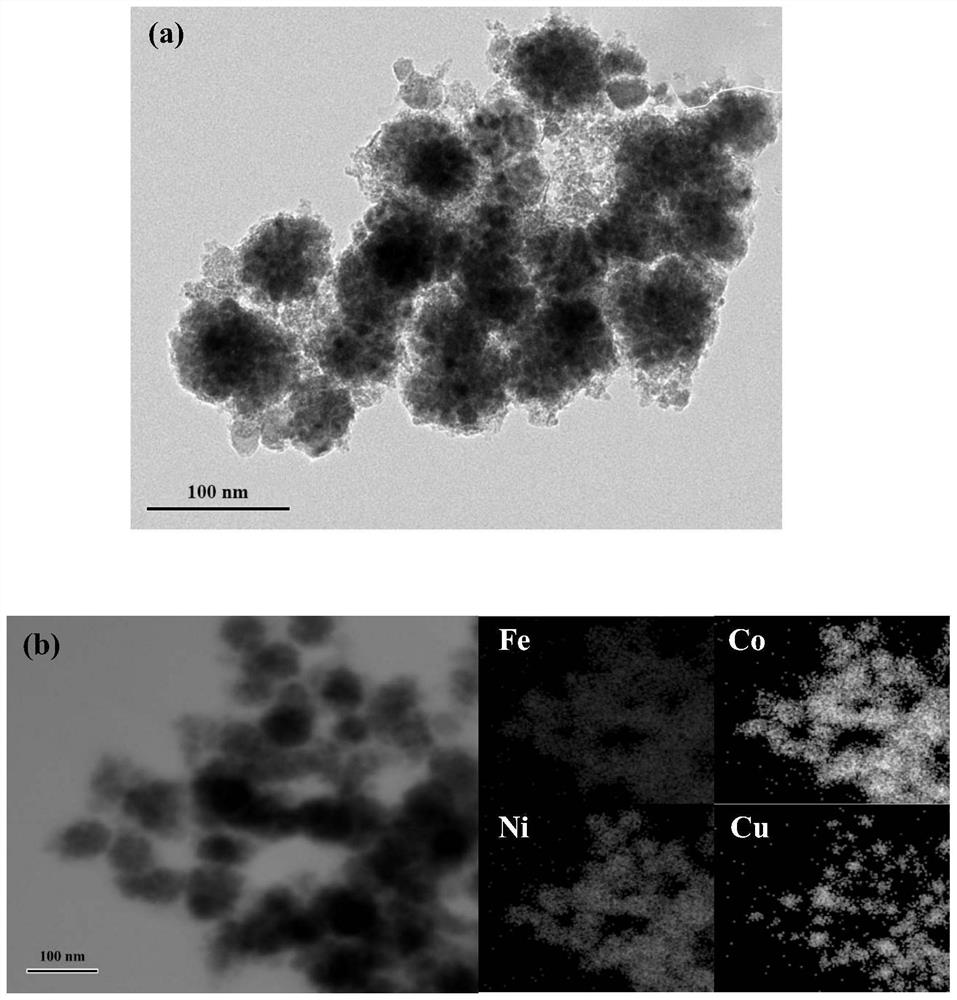

[0048] Embodiment 1: with Fe 30 co 30 Ni 30 Cu 10 As a nominal component of the high-entropy magnetic nanopowder, the metal salt (FeCl 2 4H 2 O, CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 O, CuCl 2 2H 2 O) according to the atomic percentage conversion into mass weighing, take 4g granular KOH and measure 20mL of 99.8% propylene glycol solution in a beaker, then measure a portion of 99.8% propylene glycol solution 30mL in another beaker , and add the metal salt, put into the magnetic stirring rotor. Then the propylene glycol solution and the KOH-propylene glycol solution that are dissolved with the metal salt are all placed in a magnetic stirring heater for heating, and when the temperature rises to 170° C., the propylene glycol solution that is dissolved with the metal salt is mixed with the KOH-propylene glycol solution that is filled, After 3 minutes of reaction, the heating was stopped, and the mixture was cooled to obtain a gel-like mixture. The colloidal mixture was washed t...

Embodiment 2

[0050] Embodiment 2: with Fe 40 co 25 Ni 25 Cu 10 As a nominal component of the high-entropy magnetic nanopowder, the metal salt (FeCl 2 4H 2 O, CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 O, CuCl 2 2H 2 O) according to the atomic percentage conversion into mass weighing, take 4g granular KOH and measure 20mL of 99.8% propylene glycol solution in a beaker, then measure a portion of 99.8% propylene glycol solution 30mL in another beaker , and add the metal salt, put into the magnetic stirring rotor. Then both the ethylene glycol solution in which the metal salt is dissolved and the KOH-ethylene glycol solution are placed in a magnetic stirring heater for heating. The diol solutions were mixed with each other, and the heating was stopped after reacting for 3 minutes, and cooled to obtain a gel-like mixture. The colloidal mixture was washed three times with deionized water and absolute ethanol respectively, and a black precipitate was obtained after centrifugation at 10000 rpm for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com