Production method for magnesium oxide board and production method for multi-layer composite magnesium oxide board material

A production method, glass magnesium board technology, applied in chemical instruments and methods, laminated, layered products, etc., can solve the problems of high production cost, many process steps, large processing loss, etc., and achieve small thickness error, The effect of high structural strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

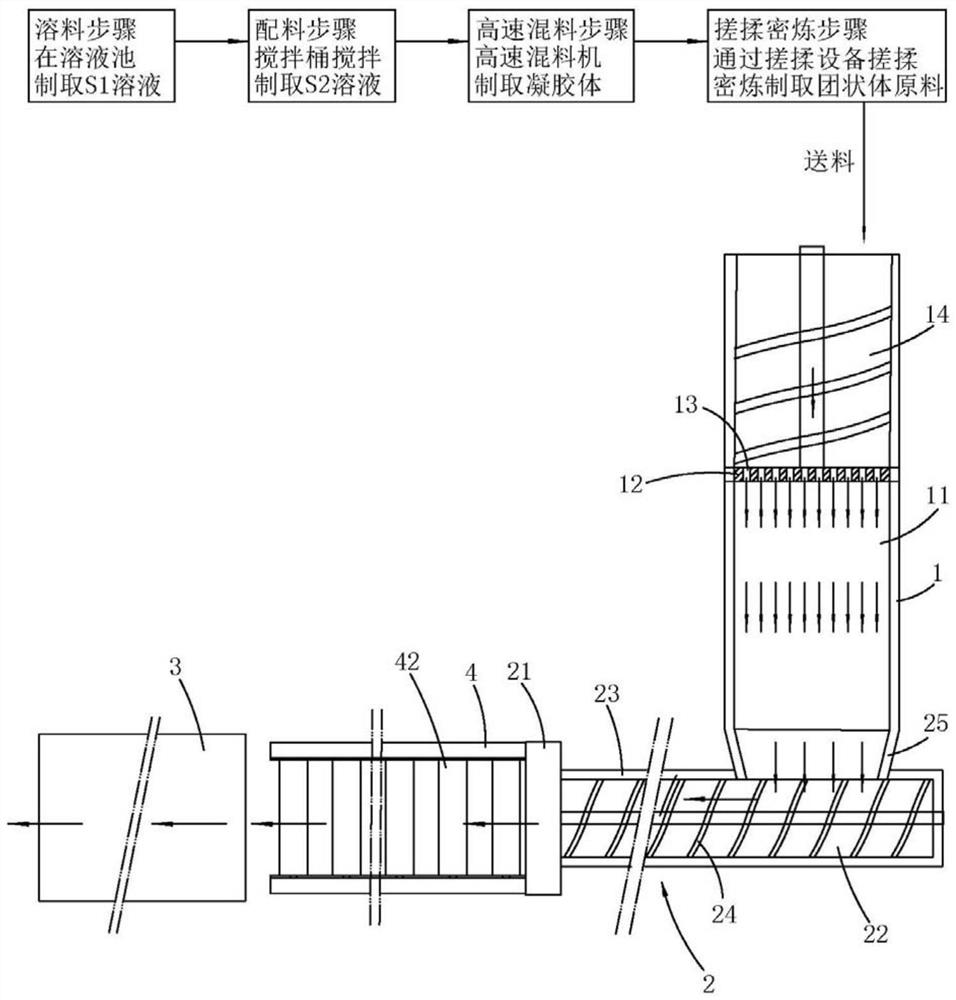

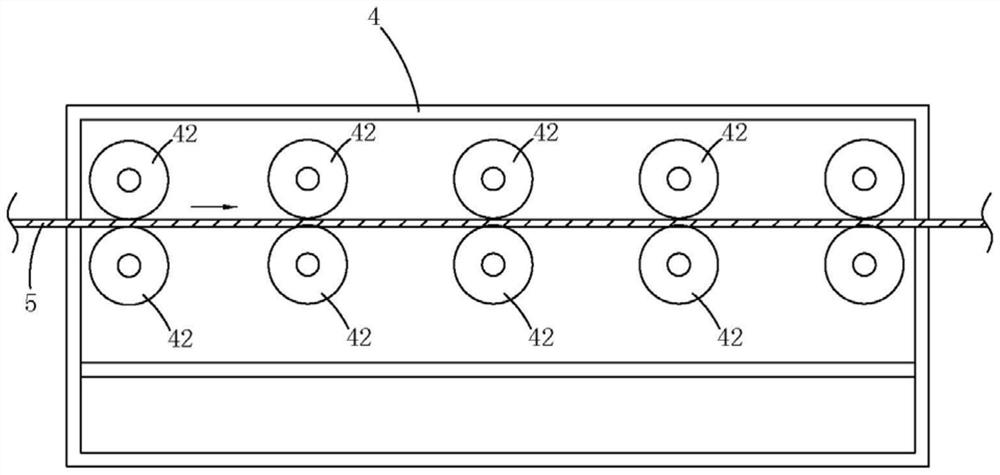

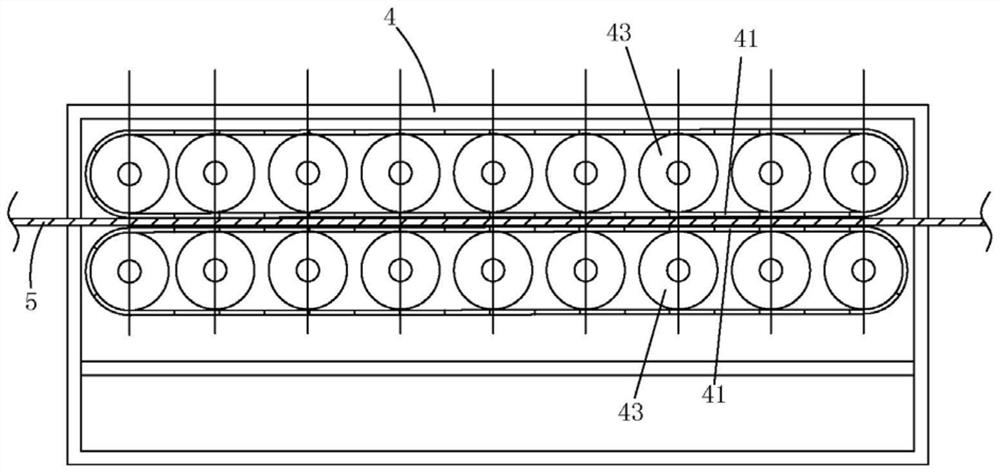

[0094] The production method of glass magnesium board, Figures 1 to 4 shown, including the following steps,

[0095] In the step of dissolving the material, the magnesium sulfate heptahydrate whose physical state is crystalline powder is poured into the solution pool filled with water, and the magnesium sulfate solution is obtained after stirring and dissolving, which is used as the S1 solution for standby, and the glassy magnesium mass concentration of the S1 solution is 26-30g / 100ml; Preferably, the water temperature of the solution pool is controlled at 20-30°C, and the weight ratio of magnesium sulfate heptahydrate to water is controlled at 1:3-4.

[0096] In the batching step, the S1 solution is poured into the mixing tank, and then the lignin fiber, magnesium sulfate modifier and polyacrylamide are put in, and the weight ratio of the S1 solution, lignin fiber, magnesium sulfate modifier and polyacrylamide is 1 : 3%: 0.2-2%: 0.2-1%, after stirring for 1-20 minutes, the...

Embodiment 2

[0138] The production method of multi-layer composite glass magnesium plate comprises the following steps,

[0139] The production steps of the finished glass magnesium board include the production method of the glass magnesium board in Embodiment 1, and the finished glass magnesium board is produced. If the length and width of the multi-layer composite glass magnesium board to be produced are smaller than the length and width of the finished glass magnesium board, cut the finished glass magnesium board according to the length and width specifications of the board to be produced, for example, cut it into a length of 60cm, width 60cm small plate, and then carry out subsequent compounding steps or other processing steps.

[0140] In the compounding step, at least one surface wear-resistant layer and a decorative layer are compounded on the finished glass magnesium plate, the surface wear-resistant layer is located on the top layer of the multi-layer composite glass magnesium pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com