A kind of KOH intercalation mxene/cnfs composite electrode material and preparation method thereof

A composite electrode and electrospinning technology is applied in the field of preparation of KOH intercalated MXene/CNFs composite electrode materials, which can solve the problems of large MXene sheets, complex synthesis methods, toxic precursors, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of KOH intercalated MXene / CNFs composite electrode material, specifically comprising the following steps:

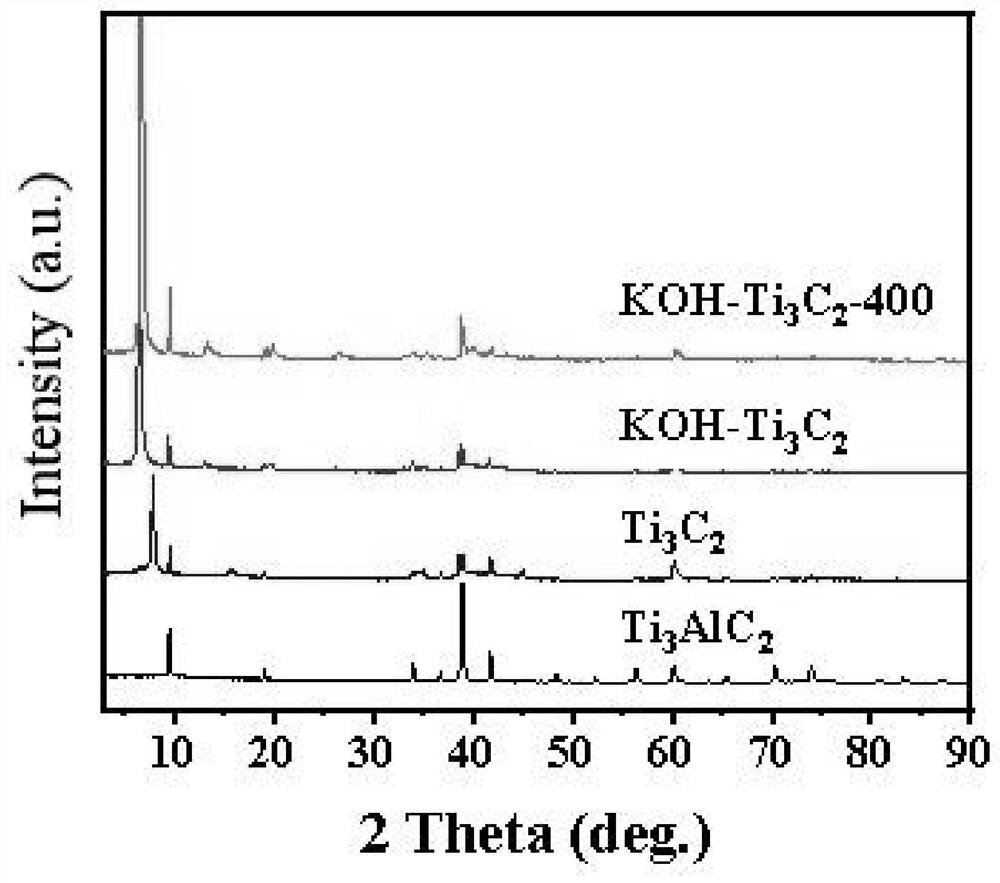

[0042] S1: The MAX phase Ti 3 AlC 2 Use LiF and concentrated HCl to etch in a water bath at 35 °C for 24 h, wash with deionized water at 10000-14000 rpm by high-speed centrifugation until the pH is neutral, and sonicate in an ice bath for 1 h in a nitrogen atmosphere to disperse into uniformly mixed Ti 3 C 2 Aqueous solution, then centrifuged at low speed at 3500-4000rpm to obtain Ti 3 C 2 Precipitation, freeze-drying for more than 10h to prepare MXene phase Ti 3 C 2 ;

[0043] S2: take the MXene phase Ti prepared in step S1 3 C 2 Soak in 1.8M KOH solution, stir under nitrogen atmosphere for about 4h, then centrifuge with deionized water for 3-5min at 10000rpm, repeat 3-4 times, the obtained precipitate is freeze-dried for more than 10h, and KOH-Ti is prepared 3 C 2 powder;

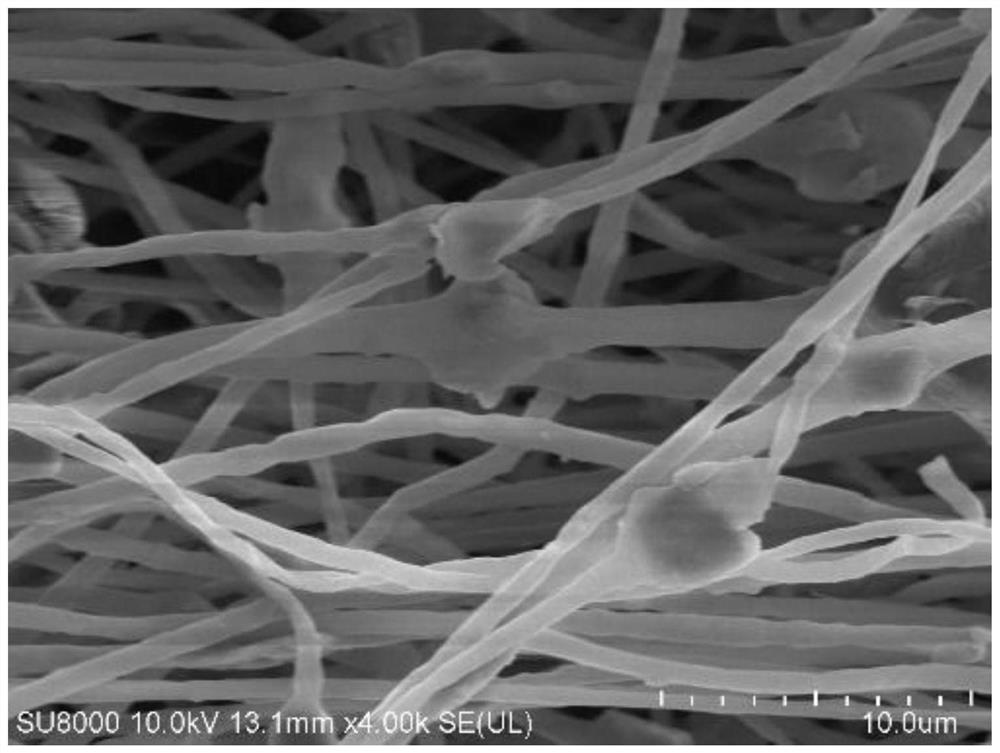

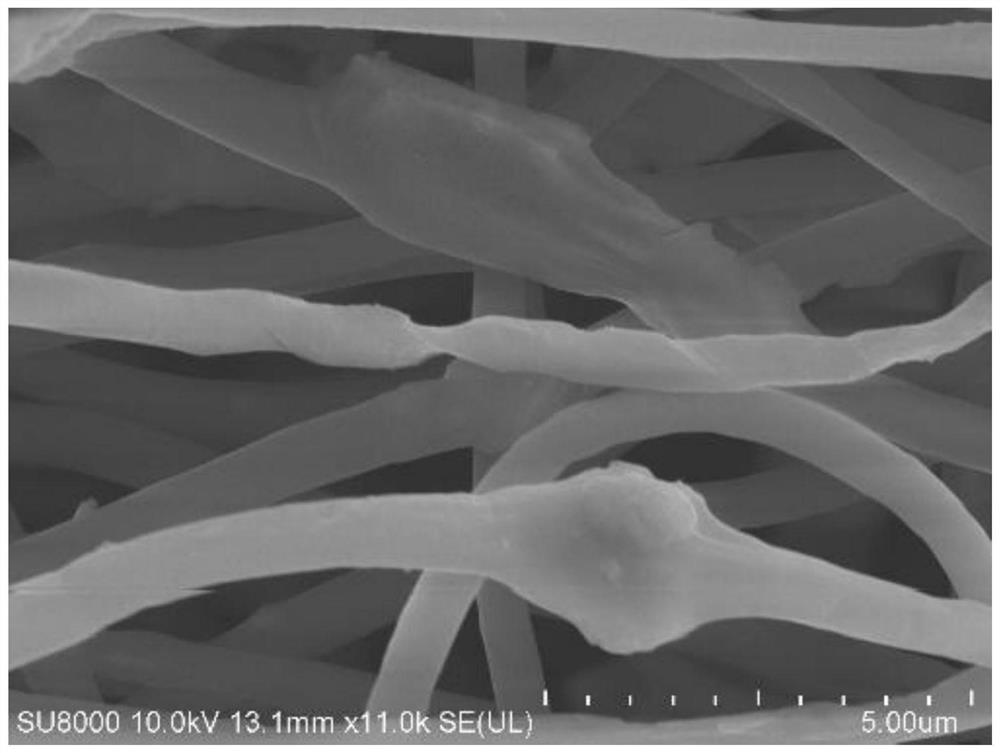

[0044] S3: the KOH-Ti prepared in step S2 3 C 2 The pow...

Embodiment 2

[0052] A preparation method of KOH intercalated MXene / CNFs composite electrode material, specifically comprising the following steps:

[0053] S1: The MAX phase Ti 3 AlC 2 Use LiF and concentrated HCl to etch in a water bath at 35 °C for 24 h, wash with deionized water at 10000-14000 rpm by high-speed centrifugation until the pH is neutral, and sonicate in an ice bath for 1 h in a nitrogen atmosphere to disperse into uniformly mixed Ti 3 C 2 Aqueous solution, then centrifuged at low speed at 3500-4000rpm to obtain Ti 3 C 2 Precipitation, freeze-drying for more than 10h to prepare MXene phase Ti 3 C 2 ;

[0054] S2: take the MXene phase Ti prepared in step S1 3 C 2 Soak in 1.8M KOH solution, stir under nitrogen atmosphere for about 4h, then centrifuge with deionized water for 3-5min at 10000rpm, repeat 3-4 times, the obtained precipitate is freeze-dried for more than 10h, and KOH-Ti is prepared 3 C 2 powder;

[0055] S3: the KOH-Ti prepared in step S2 3 C 2 The pow...

Embodiment 3

[0063] A preparation method of KOH intercalated MXene / CNFs composite electrode material, specifically comprising the following steps:

[0064] S1: The MAX phase Ti 3 AlC 2 Use LiF and concentrated HCl to etch in a water bath at 35 °C for 24 h, wash with deionized water at 10000-14000 rpm by high-speed centrifugation until the pH is neutral, and sonicate in an ice bath for 1 h in a nitrogen atmosphere to disperse into uniformly mixed Ti 3 C 2 Aqueous solution, then centrifuged at low speed at 3500-4000rpm to obtain Ti 3 C 2 Precipitation, freeze-drying for more than 10h to prepare MXene phase Ti 3 C 2 ;

[0065] S2: take the MXene phase Ti prepared in step S1 3 C 2 Soak in 1.8M KOH solution, stir under nitrogen atmosphere for about 4h, then centrifuge with deionized water for 3-5min at 10000rpm, repeat 3-4 times, the obtained precipitate is freeze-dried for more than 10h, and KOH-Ti is prepared 3 C 2 powder;

[0066] S3: the KOH-Ti prepared in step S2 3 C 2 The pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com