Preparation method of high-brightness infrared light emitting diode core and diode core

A technology of light-emitting diodes and infrared light, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of cumbersome finger pattern production, high cost, and numerous steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

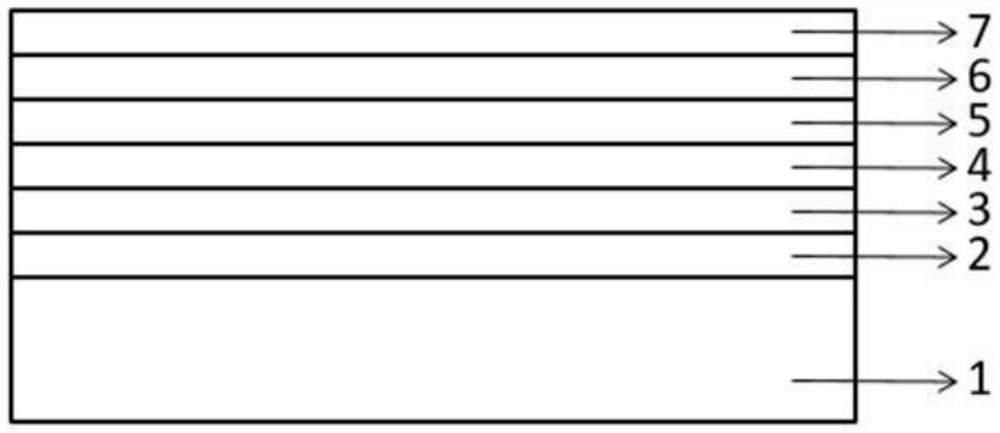

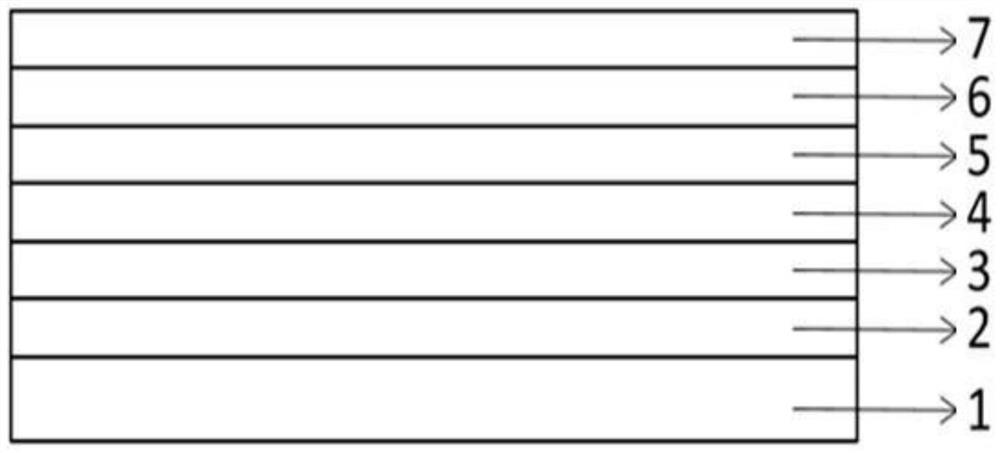

[0041] A method for preparing a high-brightness infrared light-emitting diode tube core, such as Figure 1-3 As shown, the specific steps are as follows:

[0042] (1) Wafer thinning: use photoresist to protect the front of the wafer with the epitaxial layer, and chemically polish the back with an etching solution. GaAs substrate, N-type GaAs, N-type confinement layer, MQW quantum well layer, P-type confinement layer, P-type GaAs, P-type GaP contact layer, where the back of the wafer is a GaAs substrate, and the front of the wafer is a P-type GaP contact layer ; The epitaxial layer includes N-type GaAs, N-type confinement layer, MQW quantum well layer, P-type confinement layer, P-type GaAs, and P-type GaP contact layer from bottom to top.

[0043] The corrosion solution is a mixed solution of sulfuric acid, hydrogen peroxide and water, the ratio of the corrosion solution is sulfuric acid: hydrogen peroxide: water = 5:1:1, wherein the density of sulfuric acid is 1.84g / ml, the c...

Embodiment 2

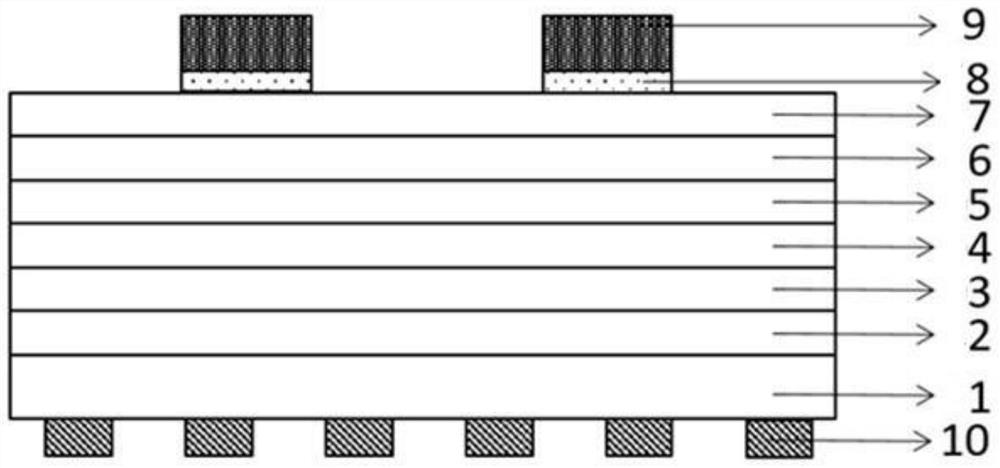

[0053] A high-brightness infrared light-emitting diode tube core is made by the preparation method of Example 1, and its structure is as follows: Figure 4 As shown, from bottom to top are adhesive film, N-side electrode, GaAs substrate, epitaxial layer, ohmic contact layer, and P-side electrode; the epitaxial layer includes N-type GaAs, N-type confinement layer, and MQW quantum well layer from bottom to top , P-type confinement layer, P-type GaAs, P-type GaP contact layer.

Embodiment 3

[0055] A method for preparing a high-brightness infrared light-emitting diode die. The difference from Embodiment 1 is that AuBe is manufactured in step (2), and the thickness is 1000 angstroms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com