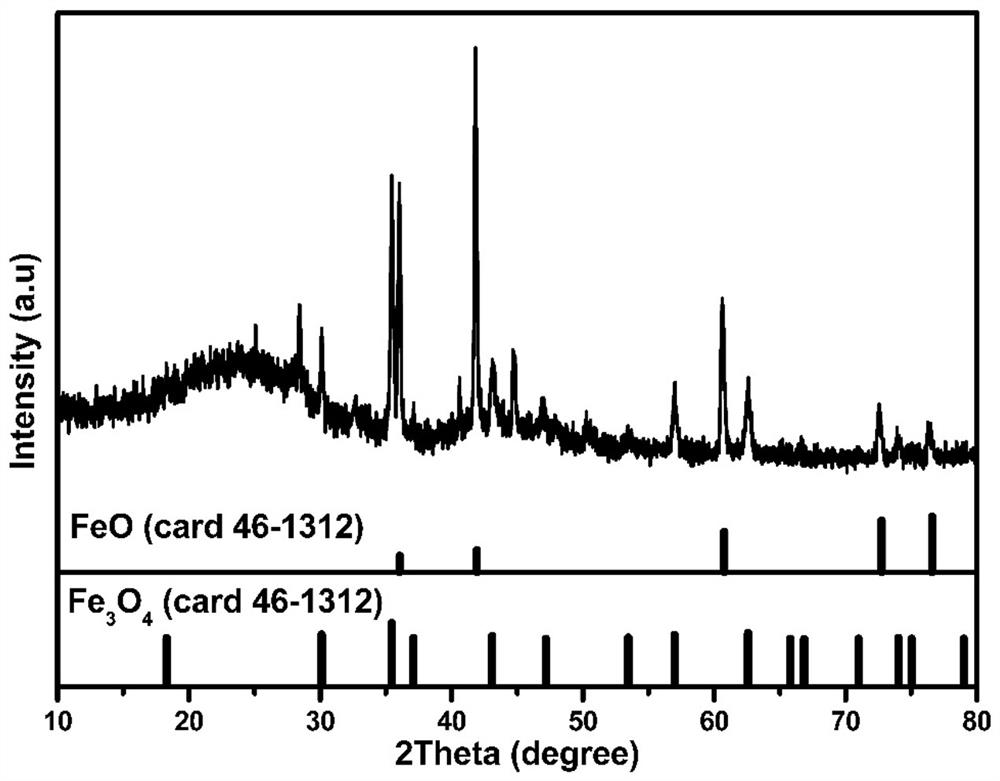

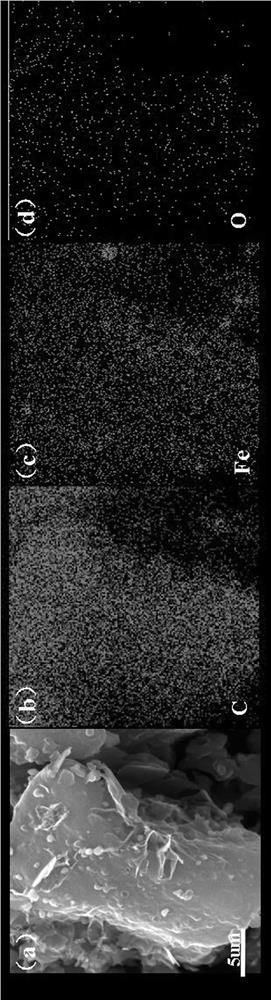

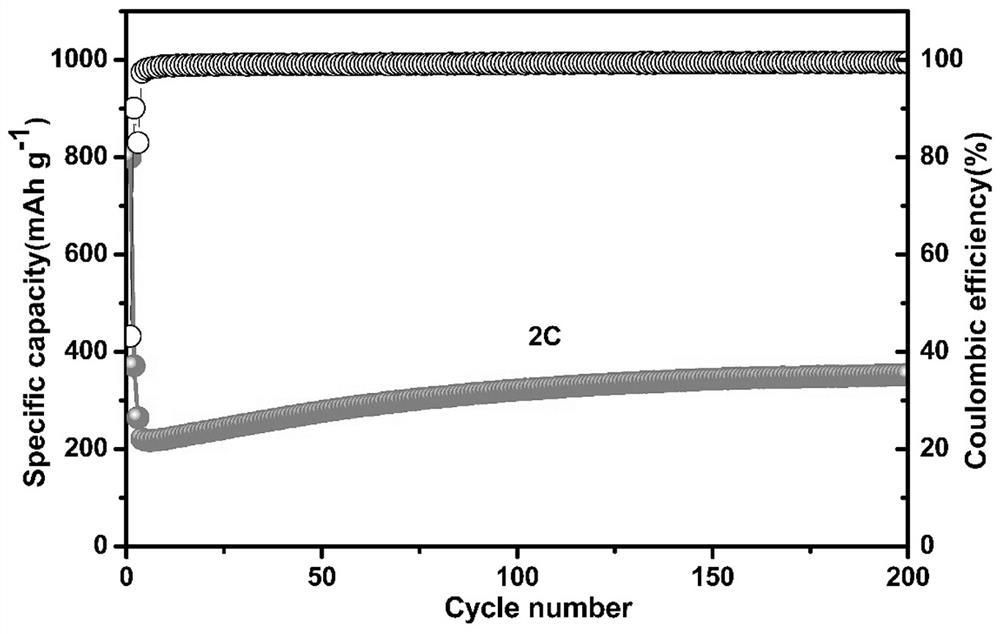

Fe3O4/FeO/C composite material, and preparation method and application thereof

A technology for composite materials and positive electrode materials, which is applied in Fe3O4/FeO/C composite materials and its preparation and application fields, can solve the problems of increased synthesis cost and complicated process, and achieve the effects of reduced preparation cost, abundant sources, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a kind of Fe 3 o 4 The preparation method of / FeO / C composite material, comprises the following steps:

[0036] (1) Disassemble the waste lithium iron phosphate battery, take out the positive electrode sheet, separate the aluminum foil and the positive electrode material in the positive electrode sheet, and add the collected positive electrode material to a solution of 3mol / L hydrochloric acid and 30%H 2 o 2 solution (the volume ratio of the two is 2:1), leaching in an open container at 50°C for 1 hour, and placing it at room temperature for 4 hours to obtain a hydrochloric acid leach solution containing lithium and iron; The concentration of lithium is 15g / L and 3g / L respectively;

[0037] (2) Pretreat the 717 type anion exchange resin with 30% sodium chloride solution to convert it into Cl - type resin, and then filled into the resin column;

[0038] (3) Send the hydrochloric acid leaching solution containing lithium and iron obtained in step (1) from the top of ...

Embodiment 2

[0048] a kind of Fe 3 o 4 The preparation method of / FeO / C composite material, comprises the following steps:

[0049] (1) Disassemble the waste lithium iron phosphate battery, take out the positive electrode sheet, separate the aluminum foil and the positive electrode material in the positive electrode sheet, and add the collected positive electrode material to a solution of 1mol / L hydrochloric acid and 30% H 2 o 2 solution (the volume ratio of the two is 2:1), leaching in an open container at 80°C for 0.5h, and standing at room temperature for 4h, to obtain a hydrochloric acid leachate containing lithium and iron; after determination, the iron in the effluent , The concentration of lithium is 20g / L and 5g / L;

[0050] (2) Pretreat the D390 anion exchange resin with 40% sodium chloride solution to convert it into Cl - type resin, and then filled into the resin column;

[0051] (3) Send the hydrochloric acid leaching solution obtained in step (1) from the top of the resin ...

Embodiment 3

[0059] a kind of Fe 3 o 4 The preparation method of / FeO / C composite material, comprises the following steps:

[0060] (1) Disassemble the waste lithium iron phosphate battery, take out the positive electrode sheet, separate the aluminum foil and the positive electrode material in the positive electrode sheet, and add the collected positive electrode material to a solution of 4mol / L hydrochloric acid and 30%H 2 o 2 solution (the volume ratio of the two is 2:1), leaching in an open container at 40°C for 3h, and standing at room temperature for 4h, to obtain a hydrochloric acid leachate containing lithium and iron; The concentration of lithium is 12g / L and 2g / L;

[0061] (2) Pretreat the 717 type anion exchange resin with 10% sodium chloride solution to convert it into Cl - type resin, and then filled into the resin column;

[0062] (3) Send the hydrochloric acid leaching solution obtained in step (1) from the top of the resin column at a flow rate of 2.5L / h, collect the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com