Preparation method for preparing cobalt-carbon catalyst through polymerization reaction and application of cobalt-carbon catalyst

A carbon catalyst, polymerization technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited industrial application, easy deactivation, high cost, and achieve high selectivity, High hydrogenation activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

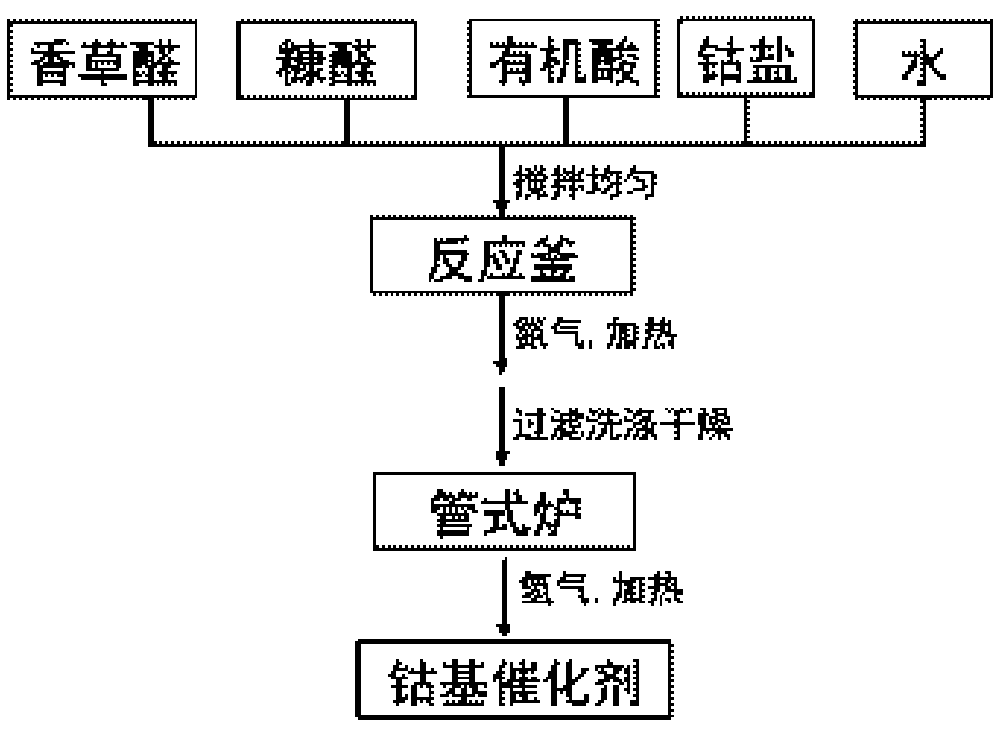

Image

Examples

Embodiment 1

[0023] Mix 5.0g vanillin, 3.2g furfural, 3g cobalt oxalate and 70g water evenly and stir for 2 hours, then put it into a high-pressure reaction kettle, pour in 3Mpa nitrogen, heat for 8 hours, and the reacted suspension is centrifuged and washed for 100 Dry at ℃ for 10 hours to obtain the precursor of the cobalt-carbon catalyst. Grind the precursor into powder and put it into a tube furnace. Calcinate at 600℃ for 4 hours in a hydrogen atmosphere. After cooling down to room temperature, blow nitrogen for 30 minutes to take out the black solid, which is the cobalt-carbon catalyst;

[0024] Add 5g furfuryl alcohol, 50mL isopropanol, 0.5g cobalt carbon catalyst into the reaction kettle, hydrogen pressure 8MPa, react at 180°C for 10h, take out the suspension and centrifuge, take the supernatant, add acetone to dilute 10 times and test it with GC-MS , the conversion of furfuryl alcohol was 100%, and the yield of 1,4-pentanediol was 78.0%.

Embodiment 2

[0026] Mix 5.0g of vanillin, 1.6g of furfural, 0.5g of organic acid, 3g of cobalt oxalate and 70g of water and stir for 2 hours, then put it into a high-pressure reactor, pour in 3Mpa nitrogen, heat for 8 hours, and the reacted suspension is passed through After centrifugal washing, dry at 100°C for 6 hours to obtain the precursor of the cobalt-carbon catalyst. Grind the precursor into powder and put it into a tube furnace. Calcinate at 700°C for 3 hours in a hydrogen atmosphere. After cooling down to room temperature, blow nitrogen gas for 30 minutes to take out the black solid. is a cobalt carbon catalyst;

[0027] Add 10g of furfuryl alcohol, 50mL of isopropanol, and 1.0g of cobalt-carbon catalyst into the reaction kettle. The hydrogen pressure is 6MPa. After reacting for 20h at 190°C, take out the suspension and centrifuge it. Take the supernatant, add acetone and dilute it 10 times, and test it with GC-MS. , the conversion of furfuryl alcohol was 100%, and the yield of 1,...

Embodiment 3

[0029] Mix 2.5g of vanillin, 3.2g of furfural, 0.5g of organic acid, 3g of cobalt oxalate and 70g of water and stir for 2 hours, then put it into a high-pressure reactor, pour in 2Mpa nitrogen, heat for 3 hours, and the reacted suspension passes through After centrifugal washing, dry at 100°C for 8 hours to obtain the precursor of the cobalt-carbon catalyst. Grind the precursor into powder and put it into a tube furnace, and calcinate it at 500°C for 2 hours in a hydrogen atmosphere. is a cobalt carbon catalyst;

[0030] Add 5g of furfuryl alcohol, 50mL of isopropanol, and 0.5g of cobalt-carbon catalyst into the reaction kettle, hydrogen pressure is 6MPa, react at 210°C for 10h, take out the suspension and centrifuge, take the supernatant, add acetone to dilute it 10 times, and test it with GC-MS , the conversion of furfuryl alcohol was 100%, and the yield of 1,4-pentanediol was 50.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com