Fe-ECR-1 zeolite as well as preparation method and application thereof

A fe-ecr-1, zeolite technology, applied in chemical instruments and methods, catalyst activation/preparation, crystalline aluminosilicate zeolite, etc., can solve the problems of long synthesis process cycle, large pollution and high cost, and achieve improved synthesis Efficiency, less waste liquid pollution, and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for Fe-ECR-1 zeolite, comprising the steps of:

[0033] Put 2.7g of silicic acid and 0.073g of anhydrous ferric chloride in 1.0g of water, adjust the pH of the solution to 1 to become an acidic aqueous solution, hydrolyze it at room temperature for 20 hours to form an iron-silicon treatment solution, and add 0.082g of NaAlO to the iron-silicon treatment solution 2 and 3mL of 20M sodium hydroxide concentrated solution to make the mixed solution alkaline, after aging for 24 hours under alkaline conditions, put the above materials in the reaction kettle, crystallize at 150°C for 5 days, cool to room temperature, and extract the product Filter and dry at 80°C to obtain Fe-ECR-1 zeolite.

[0034] The reaction raw material molar ratio of present embodiment is 1Si:0.025Al:0.01Fe:4H 2 O.

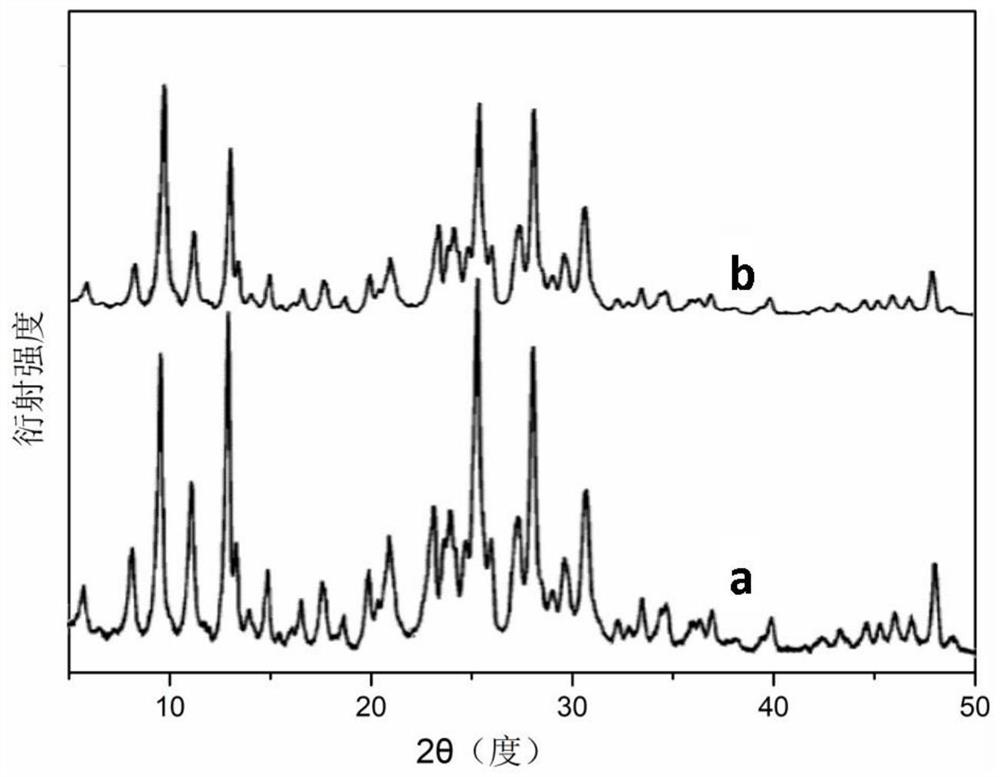

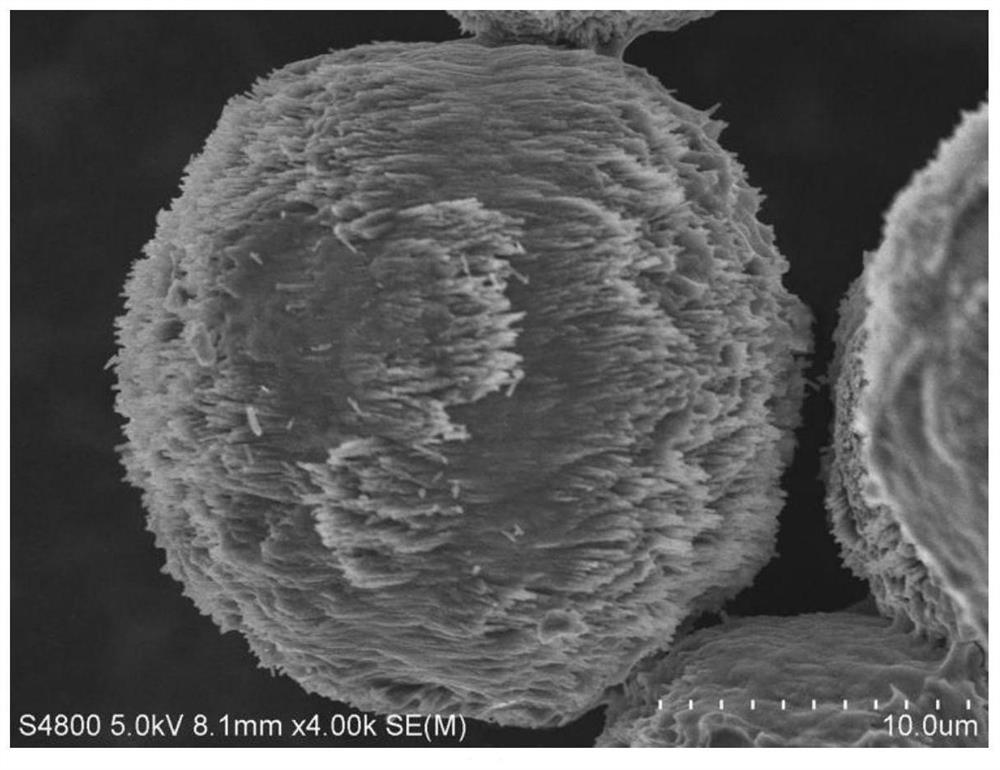

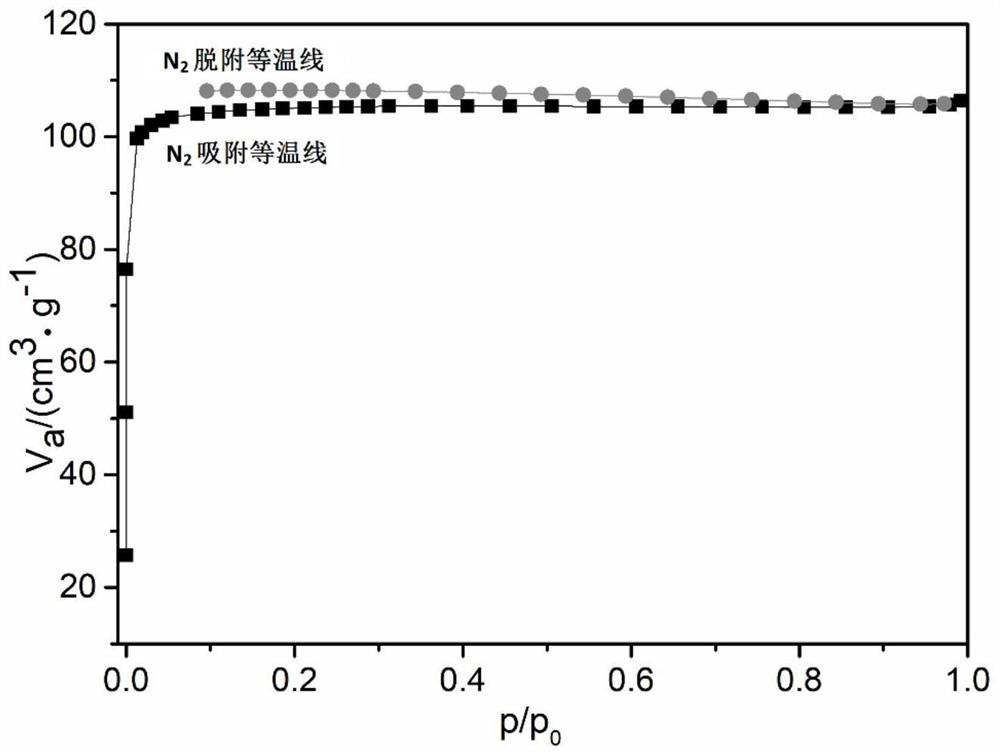

[0035] The obtained Fe-ECR-1 zeolite product is carried out X-ray diffraction, and the XRD figure is as follows figure 1 As shown in a, by figure 1 It can be seen tha...

Embodiment 2

[0039] A preparation method for Fe-ECR-1 zeolite, comprising the steps of:

[0040] Put 2.7g of silicic acid and 0.073g of anhydrous ferric chloride in 1.0g of water, adjust the pH of the solution to 1 to become an acidic aqueous solution, hydrolyze it at room temperature for 20 hours to form an iron-silicon treatment solution, and add 0.111g of NaAlO to the iron-silicon treatment solution 2 and 3.5mL of 20M sodium hydroxide concentrated solution to make the mixed solution alkaline, after aging for 24 hours under alkaline conditions, put the above materials in the reaction kettle, crystallize at 150°C for 5 days, cool to room temperature, and extract the product Filter and dry at 80°C to obtain Fe-ECR-1 zeolite.

[0041] The reaction raw material molar ratio of present embodiment is 1Si:0.034Al:0.01Fe:4.4H 2 O.

Embodiment 3

[0043] A preparation method for Fe-ECR-1 zeolite, comprising the steps of:

[0044] Put 2.7g of silicic acid and 0.073g of anhydrous ferric chloride in 1.0g of water, adjust the pH of the solution to 1 to become an acidic aqueous solution, hydrolyze it at room temperature for 20 hours to form an iron-silicon treatment solution, and add 0.164g of NaAlO to the iron-silicon treatment solution 2 and 4mL of 20M sodium hydroxide concentrated solution to make the mixture alkaline, after aging for 24 hours under alkaline conditions, put the above material in the reaction kettle, crystallize at 150°C for 5 days, and after cooling to room temperature, filter the product with suction , and dried at 80°C to obtain Fe-ECR-1 zeolite.

[0045] The reaction raw material molar ratio of present embodiment is 1Si:0.05Al:0.01Fe:4.8H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com