Electrode material preparation method, electrode material and capacitor

An electrode material, cobalt-nickel technology, applied in hybrid capacitor electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult to achieve complete exchange of ligand ions, difficult to achieve large-scale application, and strict processing requirements. Excellent electrochemical performance, convenient shape control, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Provide a kind of preparation method of electrode material, the steps are as follows:

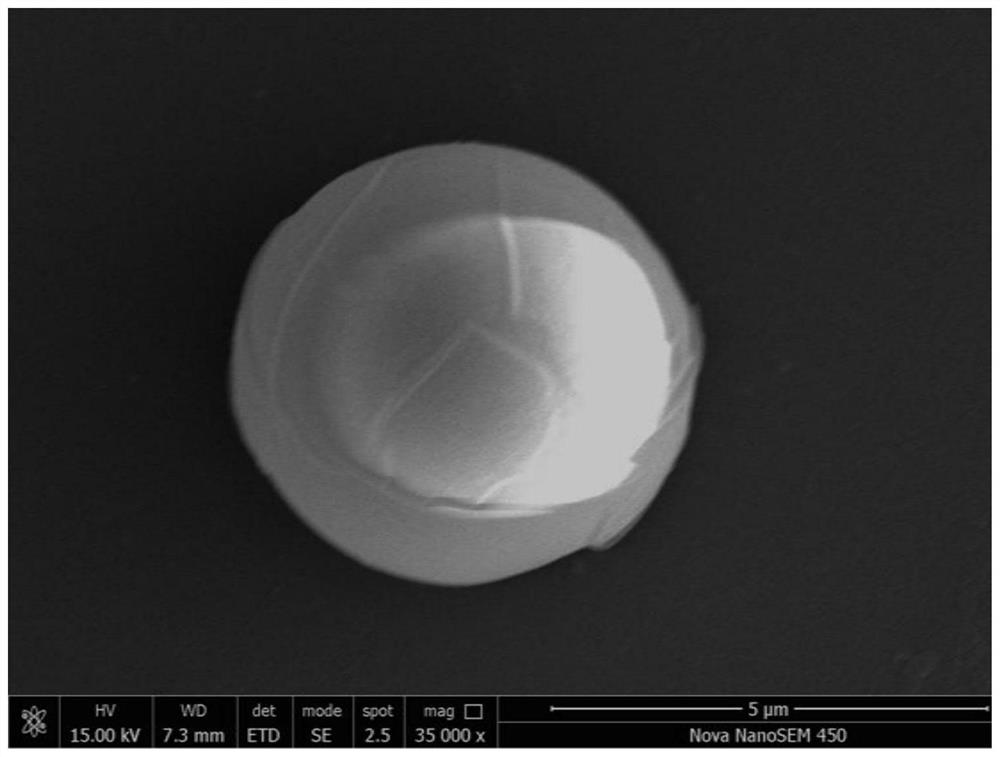

[0052] (1) Preparation of spherical cobalt-nickel complexes: 17.5ml of nickel nitrate solution with a concentration of 0.02mol / L (solvent is N, N-dimethylformamide) and 15ml of cobalt nitrate solution with a concentration of 0.01mol / L (solvent is N,N-dimethylformamide), then add 3mmol terephthalic acid and 3mmol isonicotinic acid, and finally add 32.5ml ethylene glycol solution, ultrasonic 5min to make it evenly dispersed. Transfer the mixed solution to a polytetrafluoroethylene reaction kettle, place the reaction kettle in a blast drying oven at 140°C for 72 hours, after natural cooling, wash the obtained product three times with deionized water and absolute ethanol successively, and dry overnight at 60°C After obtaining the spherical cobalt-nickel complex.

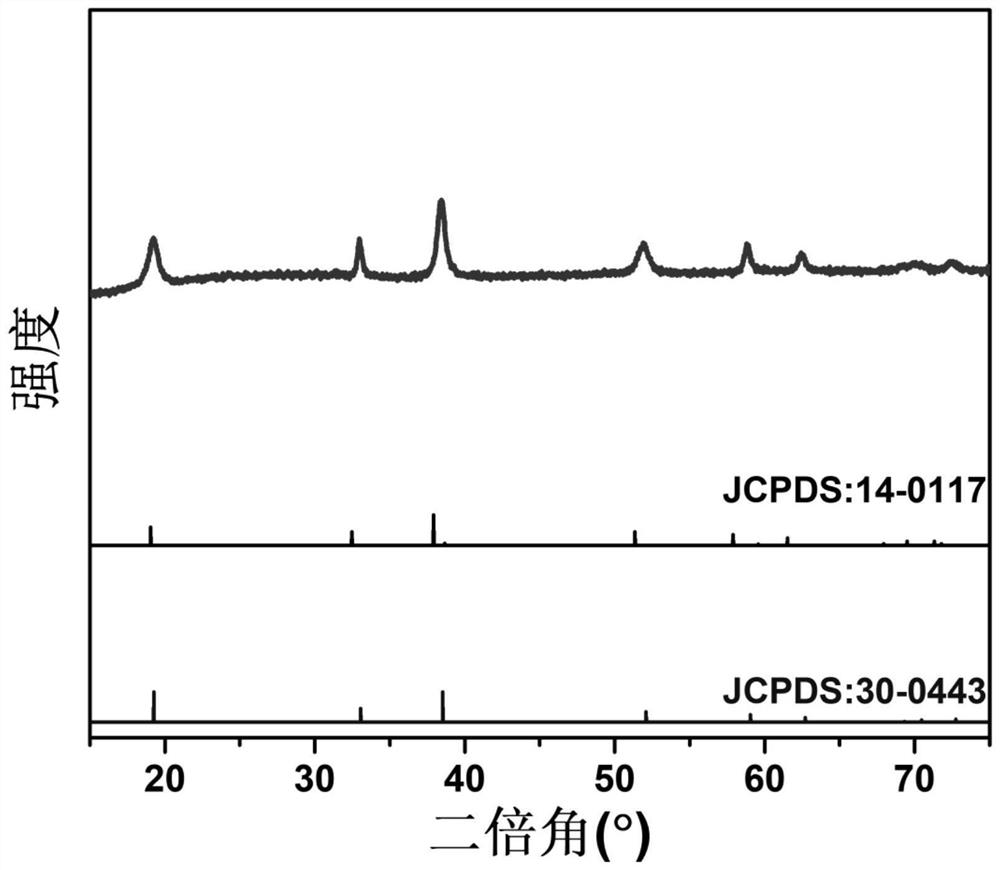

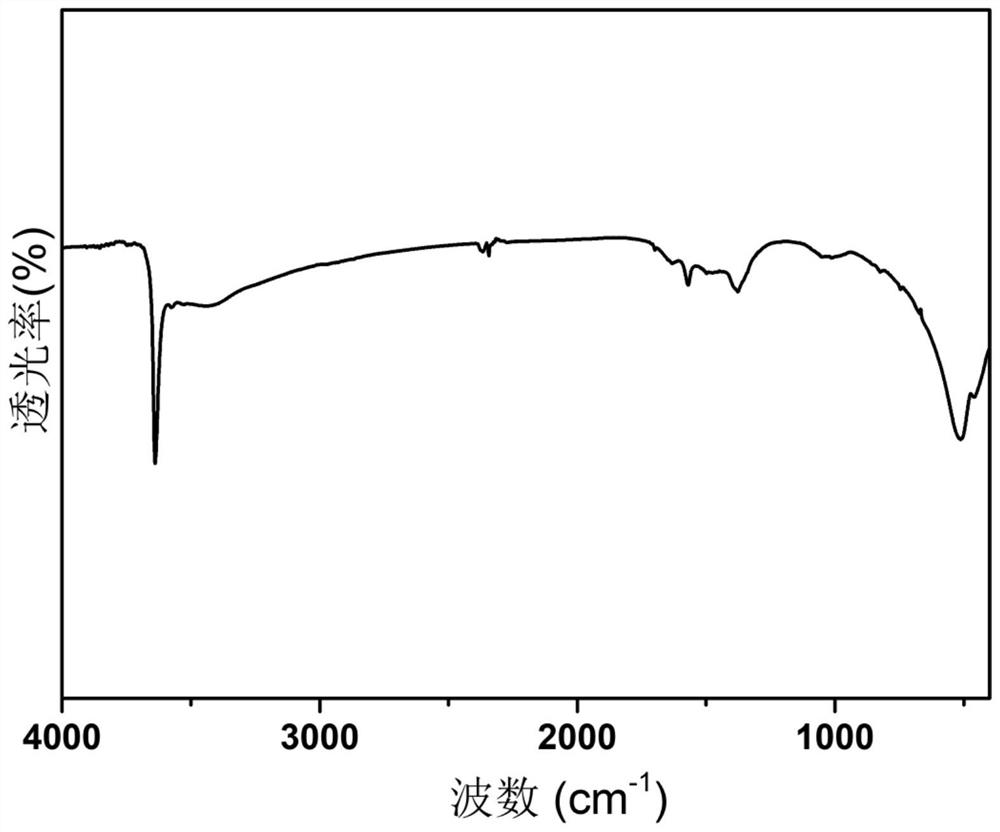

[0053] (2) Preparation of porous cobalt-nickel hydroxide electrode material: Weigh 100mg of cobalt-nickel-based complex prec...

Embodiment 2

[0055] Provide a kind of preparation method of electrode material, the steps are as follows:

[0056] (1) Preparation of spherical cobalt-nickel complexes: add 100ml of DMF / ethylene glycol (N , N-dimethylformamide) solution, ultrasonic 15min to make it evenly dispersed. Transfer the mixed solution to a polytetrafluoroethylene reaction kettle, place the reaction kettle in a blast drying oven at 150°C for 72 hours, after natural cooling, wash the obtained product three times with deionized water and absolute ethanol successively, and dry overnight at 90°C After obtaining the spherical cobalt-nickel complex.

[0057] (2) Preparation of porous cobalt-nickel hydroxide electrode material: Weigh 100mg of cobalt-nickel-based complex precursor in a 5ml glass dish, and make it float in a polytetrafluoroethylene reactor with a concentration of 0.5mol / L KOH solution, Heating for 30 minutes to keep the temperature of the reaction system at 150°C, turning the reaction kettle up and down t...

Embodiment 3

[0059] Provide a kind of preparation method of electrode material, the steps are as follows:

[0060] (1) Preparation of spherical cobalt-nickel complexes: 3mmol of nickel nitrate hexahydrate, 1.5mmol of cobalt nitrate hexahydrate, 3mmol of terephthalic acid and 3mmol of isonicotinic acid were dissolved in 30ml of DMF (N,N-dimethylformaldehyde Amide) solution, finally add an equal volume of ethylene glycol solution, ultrasonic 10min to make it evenly dispersed. Transfer the mixed solution to a polytetrafluoroethylene reaction kettle, place the reaction kettle in a forced air drying oven at 120°C for 64 hours, after natural cooling, wash the obtained product three times with deionized water and absolute ethanol successively, and dry overnight at 60°C Finally, a cobalt-nickel complex with spherical morphology was obtained.

[0061] (2) Preparation of porous cobalt-nickel hydroxide electrode material: Weigh 50mg of cobalt-nickel-based complex precursor in a 5ml glass dish, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com