Self-reinforced and toughened polyamide material and preparation method thereof

A technology for toughening polyamide and polyamide, which is applied in the field of self-reinforcing and toughening polyamide materials and their preparation, and can solve the problems of difficult implementation and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this example, the self-reinforced toughened polyamide material was prepared by the following method:

[0052] (1) Dry the PA1012 pellets in a vacuum oven at a temperature of 105°C for 10 hours to obtain anhydrous PA1012 raw materials, and the melting point of PA1012 is 190°C;

[0053] (2) Put the anhydrous PA1012 obtained in step (1) into a heat treatment environment, repeatedly discharge the remaining air in the heat treatment environment before heating up, and heat up to 210°C for 3 hours under the condition of continuous high-purity helium gas , to obtain the product.

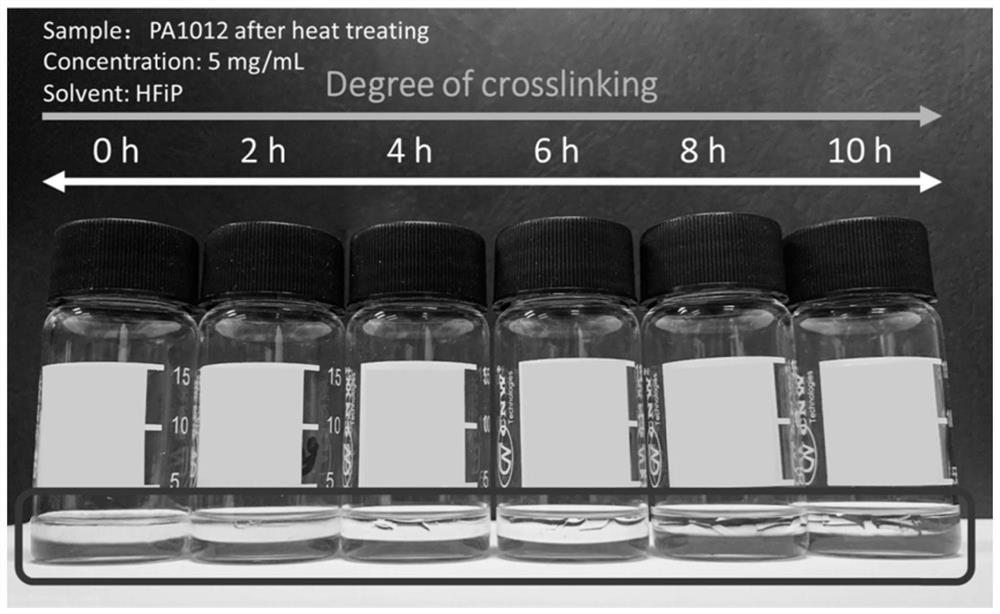

[0054] The heat-treated product was dissolved in hexafluoroisopropanol, and the solvent was added at a concentration of 10 mg / ml. It was found that part of the material was insoluble and formed a gel.

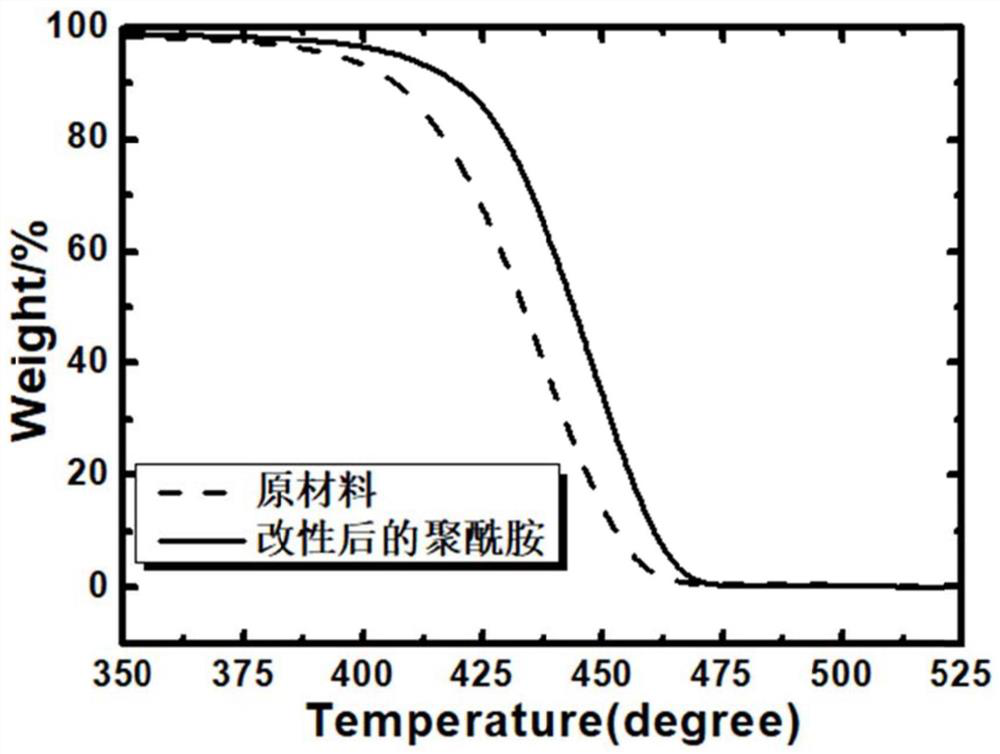

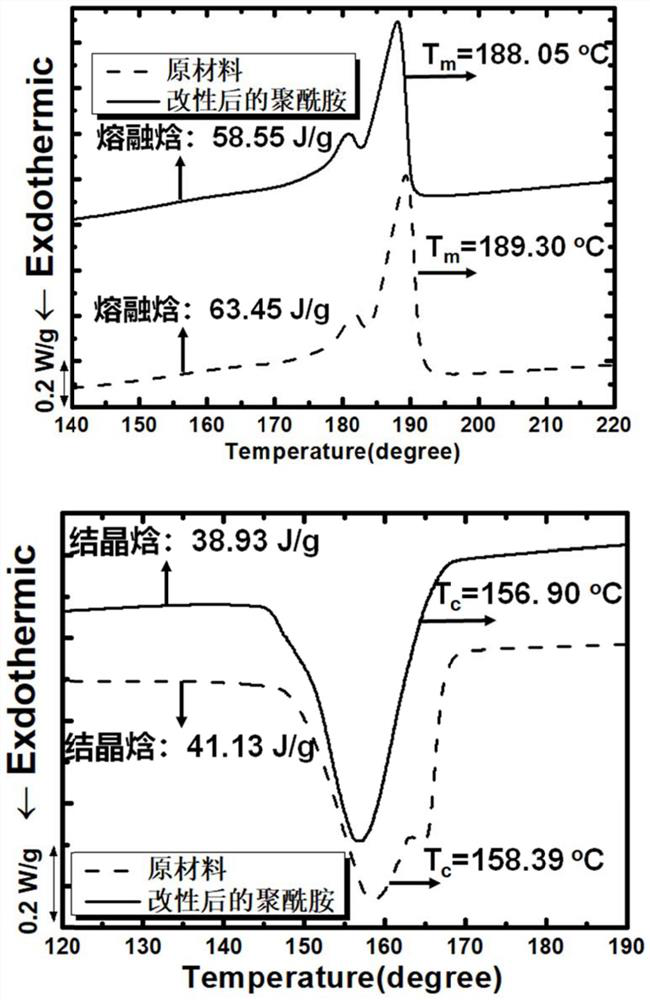

[0055] The PA1012 product that present embodiment obtains after heat treatment is carried out heat stability test, and its thermal decomposition temperature (T 95 ) is 398 ° C, compared with PA101...

Embodiment 2

[0057] In this example, the self-reinforced toughened polyamide material was prepared by the following method:

[0058] (1) Dry the PA1212 pellets in a vacuum oven at a temperature of 70°C for 12 hours to obtain anhydrous PA1212 raw materials, and the melting point of PA1212 is 180°C;

[0059] (2) Put the anhydrous PA1212 obtained in step (1) into a heat treatment environment, repeatedly discharge the remaining air in the heat treatment environment before heating up, and heat up to 200°C for 6 hours under the condition of high-purity nitrogen, get the product.

[0060] The heat-treated product was dissolved with concentrated sulfuric acid, and the solvent was added at a concentration of 5 mg / ml. It was found that some materials were insoluble and formed a gel. The dissolved photos and DSC data can help explain.

[0061] The PA1212 product that present embodiment obtains after heat treatment is carried out heat stability test, and its thermal decomposition temperature (T 95 )...

Embodiment 3

[0063] In this example, the self-reinforced toughened polyamide material was prepared by the following method:

[0064] (1) Dry the PA66 pellets in a vacuum oven at a temperature of 100°C for 5 hours to obtain anhydrous PA66 raw materials, and the melting point of PA66 is 260°C;

[0065] (2) Put the anhydrous PA66 obtained in step (1) into a heat treatment environment, repeatedly discharge the remaining air in the heat treatment environment before heating up, and heat up to 265°C for 10 hours under constant vacuum conditions to obtain the product .

[0066] The heat-treated product was dissolved with trifluoroacetic acid, and the solvent was added at a concentration of 0.5 mg / ml. It was found that some materials were insoluble and formed a gel.

[0067] The PA66 product that present embodiment obtains after heat treatment is carried out thermal stability test, and its thermal decomposition temperature (T 95 ) is 414 ° C, compared with PA66 without heat treatment, it has incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com