Deep denitrification and decolorization system for chemical wastewater

A technology for deep denitrification and chemical wastewater, applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow decolorization effect and difficulty in reaching the standard of effluent, and achieve low removal rate and avoid clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

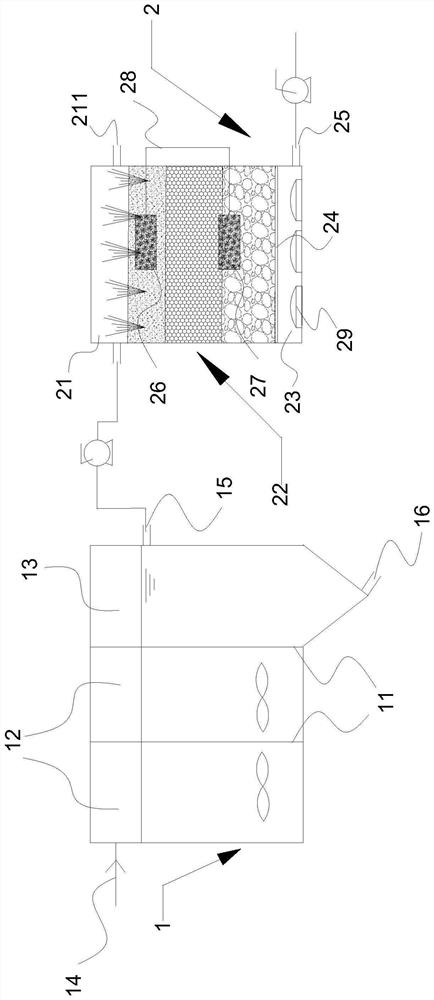

[0032] Such as figure 1 As shown, a chemical wastewater deep denitrification and decolorization system includes a pretreatment pool 1 and a bioelectrochemical treatment pool 2, and a partition 11 is arranged in the pretreatment pool, and the partition 11 divides the pool body of the pretreatment pool 1 It is divided into two flocculation tanks 12 and sedimentation tanks 13 with the upper part connected and the lower part separated. The lower part of the adjacent flocculation tanks 12 is connected. Connected, the upper end of the sedimentation tank 13 is provided with a water outlet 15, and the lower end is provided with a mud discharge port 16, and an inverted cone is formed between the body of the sedimentation tank 13 and the mud discharge port 16 at the bottom;

[0033] The pool body of the bioelectrochemical treatment pool 2 is sequentially divided into a water inlet area 21, a supporting area 22, and a water outlet area 23 from top to bottom, and a through-hole partition ...

Embodiment 2

[0036] Attached below figure 1 Describe the motion process of the system:

[0037]The wastewater to be treated enters the flocculation tank 12 through the wastewater inlet pipe 14, and a flocculant is added to the flocculation tank 12. Under the action of the agitator at the bottom of the flocculation tank, the flocculant reacts quickly with the SS in the water body. The first flocculation tank The flocculant added in 12 is iron salt, and the flocculant added in the second flocculation tank 12 is PAM. Quickly form flocs, and the flocs quickly settle at the bottom of the sedimentation tank 13 without power to form sludge, and the sludge can be discharged through the sludge discharge port 16;

[0038] The upper part of the sedimentation tank 13 is provided with a water outlet 15, and the sewage treated by the pretreatment tank 1 enters the bioelectrochemical treatment tank 2 through the water outlet 15, and the organic matter in the sewage is decomposed by the microorganisms on...

Embodiment 3

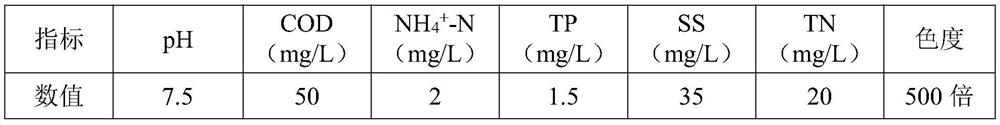

[0041] use figure 1 The wastewater treatment system shown is used as the treatment group; other systems are the same as those of the treatment group, and a control group is set at the same time. The wastewater treatment system in the control group is basically the same as the treatment group, except that the anode electrode, cathode electrode and conductive wire are not set. The water quality standards of the wastewater to be treated are as follows in Table 1:

[0042] Table 1 Water quality standards of wastewater to be treated

[0043]

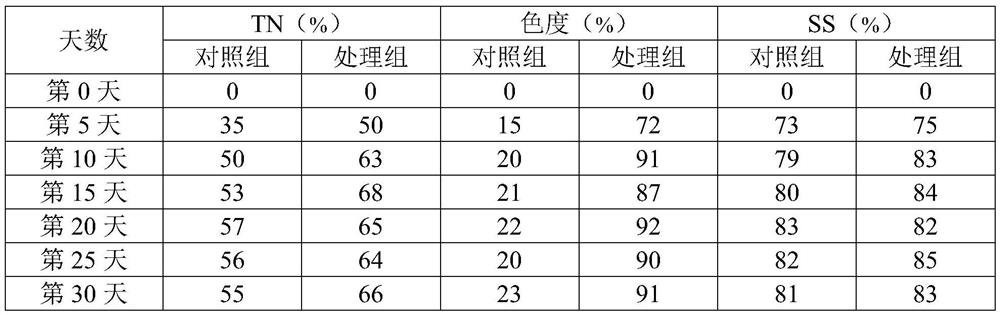

[0044] The reactors of the treatment group and the control group were all operated continuously for 30 days, and the removal rate of relevant indicators was shown in the following table 2 with the change of the number of days of reactor operation:

[0045] Table 2 The removal rate of each water quality in the control group and the experimental group

[0046]

[0047] In order to verify the denitrification and decolorization effect of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com