Magnesium-based metal polymer composite bone-guided regeneration membrane and preparation method thereof

A magnesium-based metal, guided regeneration technology, applied in the field of medical materials, dental implant filling materials and antibacterial implant materials, can solve the problems of insufficient activity of osteoconductive membrane, no antibacterial, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

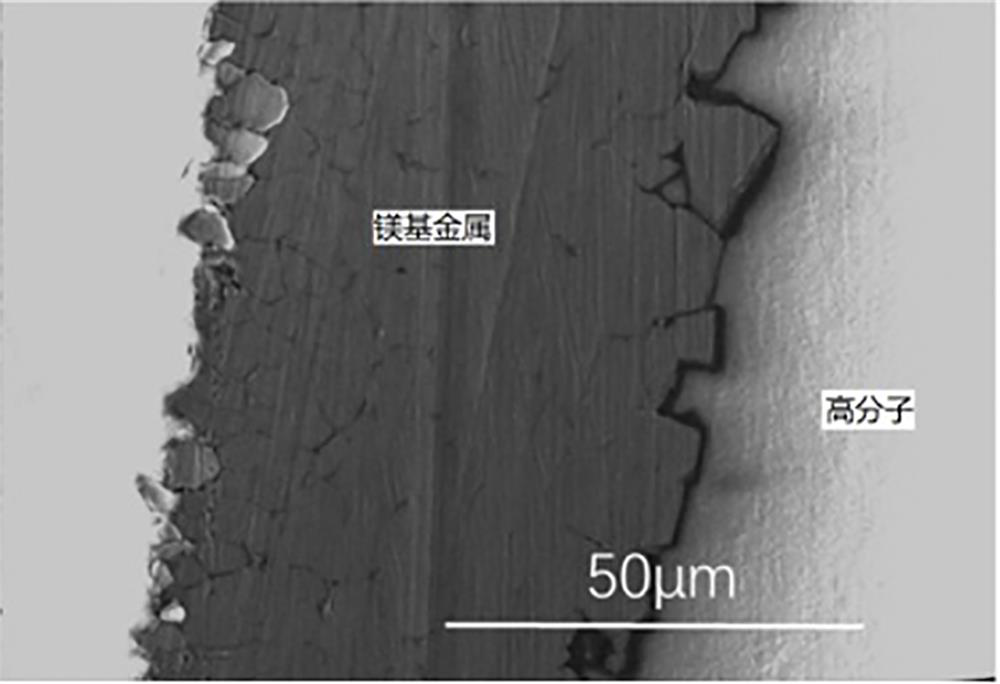

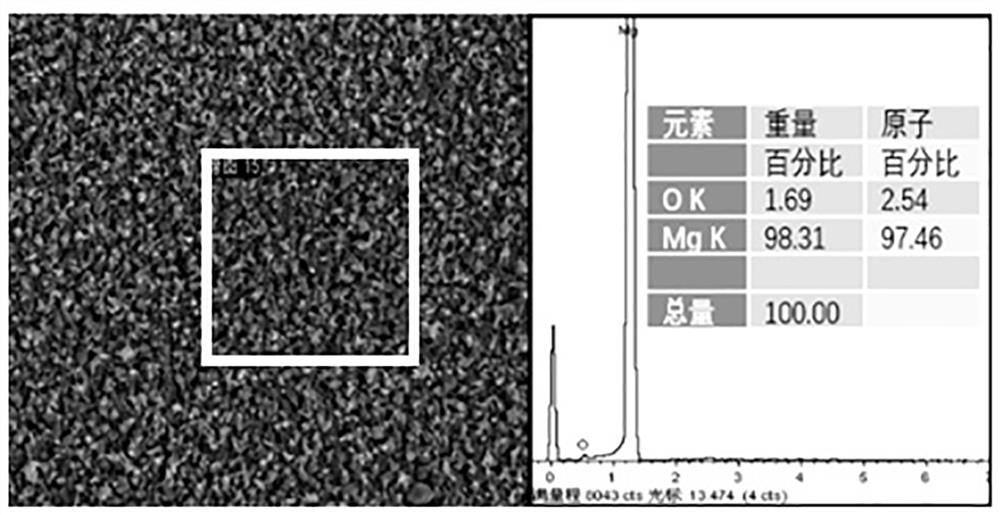

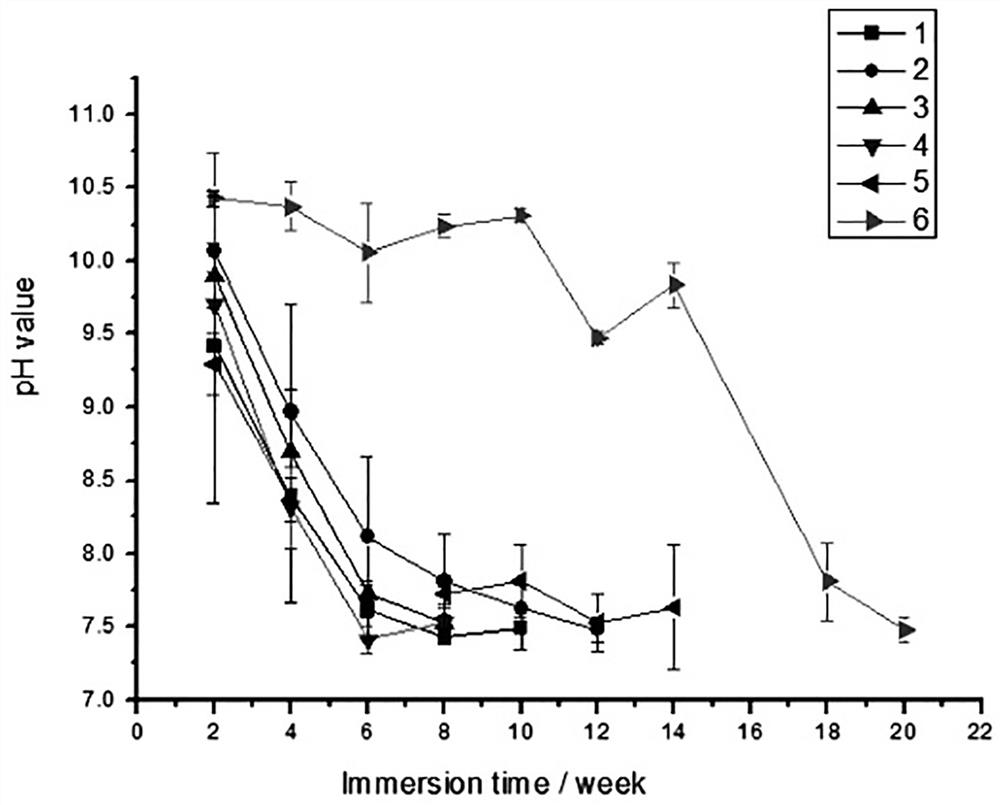

[0026] The polyvinyl alcohol sheet is placed in the furnace body of the deposition chamber, with a thickness of 0.5 mm, a length of 2 cm, and a width of 1 cm. Place the magnesium raw material in the evaporation chamber. The content of Cu is 0.2%, the content of Zn is 1%, the balance is Mg, and the ultimate vacuum (10 -4 Pa). Set the sublimation temperature of the magnesium-based metal to 400°C and the working pressure to 1×10 -3 Pa, the deposition temperature is 150°C, and the deposition time is 30 min. The sample is taken out after cooling with the furnace. The thickness of the magnesium-based metal coating is 100 µm. The degradation rate of the magnesium-based metal coating is higher than that of the polymer material layer, and the degradation time is about 25 days, and the polymer material layer is completely degraded for ≥10 weeks.

Embodiment 2

[0028] Place the polylactic acid sheet in the furnace body of the deposition chamber, with a thickness of 0.2 mm, a length of 4 cm, and a width of 2 cm. Put the pure magnesium raw material in the evaporation chamber. Ultimate vacuum (10 -4 Pa). Set the sublimation temperature of the magnesium-based metal to 450°C and the working pressure to 1×10 -2 Pa, the deposition temperature is 200°C, the deposition time is 60min, the sample is taken out after cooling in the furnace, the thickness of the magnesium-based metal coating is 200µm, the degradation time of the magnesium-based metal coating is about 30 days, and the complete degradation time of the polymer material layer is ≥10 week.

Embodiment 3

[0030] The polyacrylic acid sheet is placed in the furnace body of the deposition chamber, with a thickness of 0.8 mm, a length of 3 cm, and a width of 1 cm. The magnesium raw material is placed in the evaporation chamber. The content of Cu is 0.5%, the content of Zn is 3%, the content of Sr is 2%, the balance is Mg, and the limit vacuum (10 -4 Pa). Set the sublimation temperature of the magnesium-based metal to 450°C and the working pressure to 1×10 -2 Pa, the deposition temperature is 100°C, the deposition time is 60min, the sample is taken out after cooling with the furnace, the thickness of the magnesium-based metal coating is 200µm, the degradation time of the magnesium-based metal coating is about 20 days, and the polymer material layer is completely degraded in ≥8 week. Magnesium is degraded to be alkaline and polyacrylic acid is degraded to be acidic, so the degradation of both materials will be accelerated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com