Fluorine adsorbing material, preparation method thereof, and fluorine-containing wastewater treatment method using fluorine adsorbing material

A technology for adsorbing materials and wastewater, applied in the field of fluorine adsorption, which can solve the problems of huge size and complex treatment facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

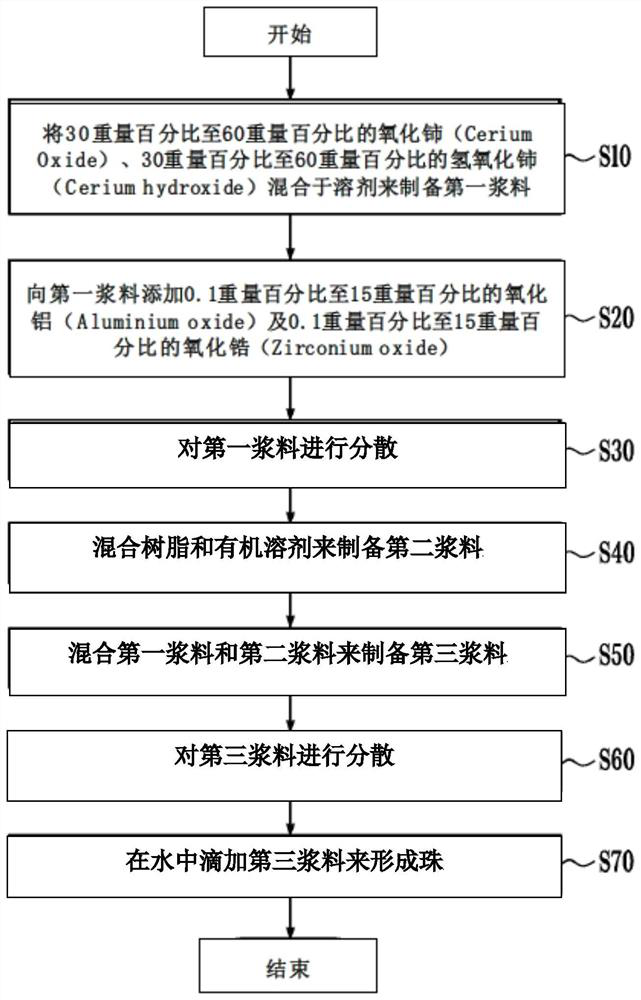

[0076] The preparation method of the fluorine adsorption material of the present invention comprises: step (a-1), mixing 30% by weight to 60% by weight of cerium oxide (Cerium Oxide) and 30% by weight to 60% by weight of cerium hydroxide (Ceriumhydroxide) solvent to prepare the first slurry; step (a-2), adding 0.1% by weight to 15% by weight of aluminum oxide (Aluminium oxide) and 0.1% by weight to 15% by weight of zirconia (Zirconium oxide) to the above-mentioned first slurry ); Step (a-3), dispersing the above-mentioned first slurry; Step (a-4), mixing resin and organic solvent to prepare the second slurry; Step (a-5), mixing the above-mentioned first slurry and the second slurry to prepare a third slurry; step (a-6), dispersing the above third slurry; and step (a-7), adding the above third slurry dropwise in water to form beads.

[0077] Firstly, 30 to 60 weight percent of cerium oxide and 30 to 60 weight percent of cerium hydroxide are mixed in a solvent to prepare a first...

Embodiment 1

[0165] Embodiment 1. Preparation of fluorine adsorption material

[0166] 1) Preparation of the first slurry (Slurry): Mix 4 kg of cerium oxide and 5 kg of cerium hydroxide, and add 500 g each of alumina and zirconia to prepare a mixture. The above-mentioned mixture and dimethyl sulfoxide were mixed at a weight ratio of 1:1, filled in a vessel (Vessel), dispersed, and refined to prepare a first slurry.

[0167] 2) Preparation of the second slurry: 10% (v / v) of ethylene vinyl alcohol resin was dissolved in dimethyl sulfoxide (DMSO), followed by purification to prepare a second slurry.

[0168] 3) Mixing of the slurry: After putting the above-mentioned first slurry and the second slurry into the reactor at a weight ratio of 1:2, they were stirred with a shaker and then dispersed to prepare the third slurry.

[0169] After the third slurry is dispersed, it is refined.

[0170] 4) Preparation of beads: Water was prepared in the reactor, and the third slurry was added dropwise th...

experiment example 1

[0176] Experimental example 1: Confirmation of fluorine adsorption capacity of fluorine adsorption material

[0177] The fluorine adsorption material was prepared according to Example 1, and the content of cerium oxide and cerium hydroxide was changed to confirm the adsorption capacity of the fluororesin.

[0178] Table 1

[0179] Sample (No.) 1 2 3 4 5 6 Cerium oxide (kg) 2 3 4 5 6 7 Cerium hydroxide (kg) 7 6 5 4 3 2 Alumina (kg) 0.5 0.5 0.5 0.5 0.5 0.5 Zirconia (kg) 0.5 0.5 0.5 0.5 0.5 0.5 Fluoride ion (ppm) 4.3 2.9 2.8 2.5 2.3 2.4 Chloride ion (ppm) 790 785 783 784 785 790 nitric acid (NO 3 - )(ppm)

223 210 211 209 210 222

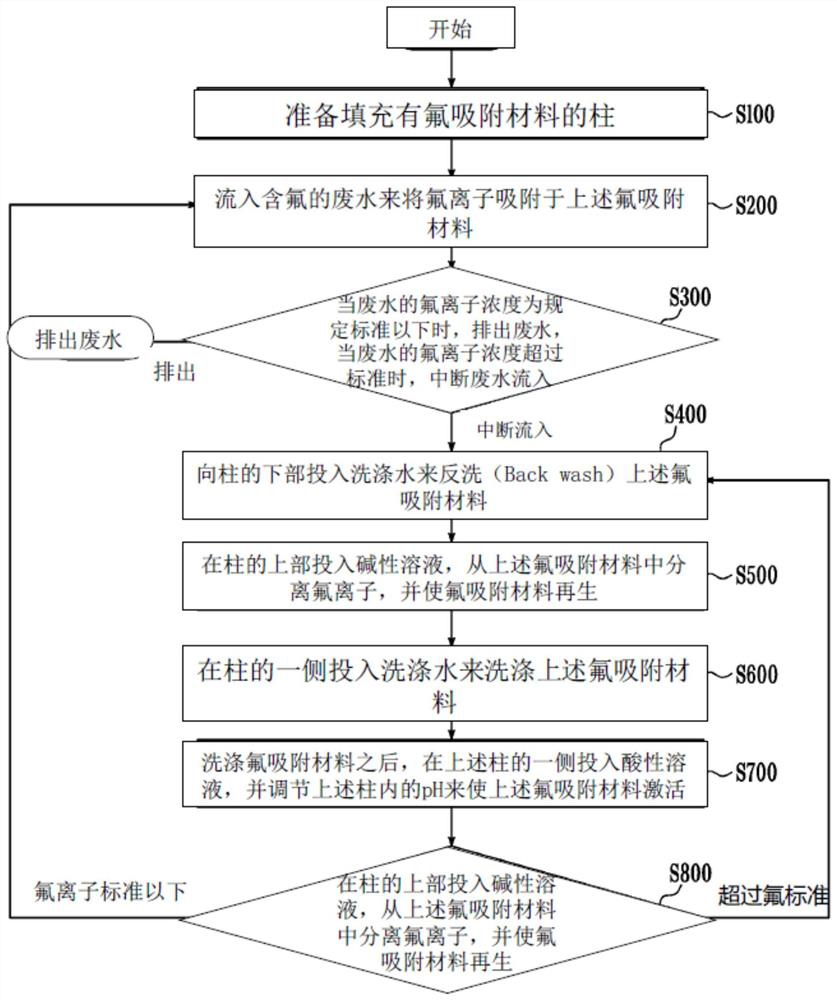

[0180] The prepared fluorine adsorption material was filled in a column with a diameter of 50 cm.

[0181] After the initial washing, the fluorine adsorbing material was activated by pretreatment of alkaline washing and washing with 0.3N sodium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com