Recyclable packaging material and preparation method thereof

A packaging material and peeling layer technology, applied in the field of recyclable packaging materials and their preparation, can solve the problems of low decomposition temperature, poor bonding strength, limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] Add 1 mol of vinylpyrrolidone and 1 mol of acrylamide into 1 L of deionized water, stir the mixture for one hour under nitrogen purging, then add 2.2 g of ceric ammonium nitrate and 4 mL of 1N HNO to the system within 2 hours 3 Initiator solution in 90mL of water, heated to 40°C for polymerization reaction, after 10 hours, the obtained polymer gel was added to methanol for precipitation, the solid product was separated and washed with methanol, and then dried to obtain vinylpyrrolidone-propylene Amide copolymer 173g, determined by analysis vinylpyrrolidone-acrylamide copolymer contains 47mol% units derived from acrylamide, 53mol% units derived from vinylpyrrolidone, the number average molecular weight of the copolymer is 7.5 × 10 4 g / mol.

Embodiment 1

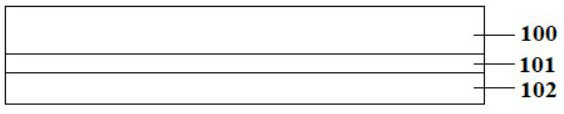

[0069] 15g of the vinylpyrrolidone-acrylamide copolymer of Preparation Example 1, 3g of sodium polyacrylate (number average molecular weight 2.2×10 4 g / mol, the same below) was heated and dissolved in 82g of water to form an aqueous solution, which was coated on a 15 μm thick aluminum foil layer 102 and dried at 90°C to form a 3 μm thick first peeling layer 101 on the aluminum foil layer 102. Then, a 35 μm thick polyethylene layer 100 (melt flow rate 16g / 10min, the same below) extrusion coating on the first release layer 101 to prepare a three-layer aluminum foil packaging film. The aluminum foil packaging film of the three-layer structure is as figure 1 shown.

Embodiment 2

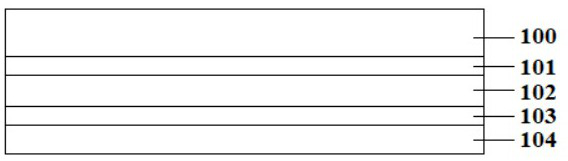

[0071] 15 g of the vinylpyrrolidone-acrylamide copolymer of Preparation Example 1 and 5 g of sodium polyacrylate were heated and dissolved in 80 g of water to form an aqueous solution, which was coated on a 15 μm thick aluminum foil layer 102 and dried at 90° C. to form an aqueous solution on the aluminum foil layer. 102 is formed with a first peeling layer 101 with a thickness of 3 μm. Then, a 35 μm thick polyethylene layer 100 was extrusion coated on the first release layer 101 at a processing temperature of 300° C. using a slit extrusion type coater to prepare a three-layer structure aluminum foil packaging film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com