Solid oxide fuel cell electrolyte film preparation method

An electrolyte film and solid oxide technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high electrolyte electronic conductivity, high electrolyte internal resistance, leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

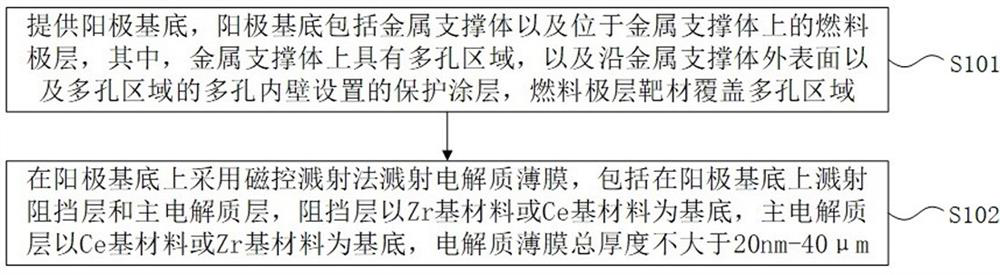

Image

Examples

Embodiment 1

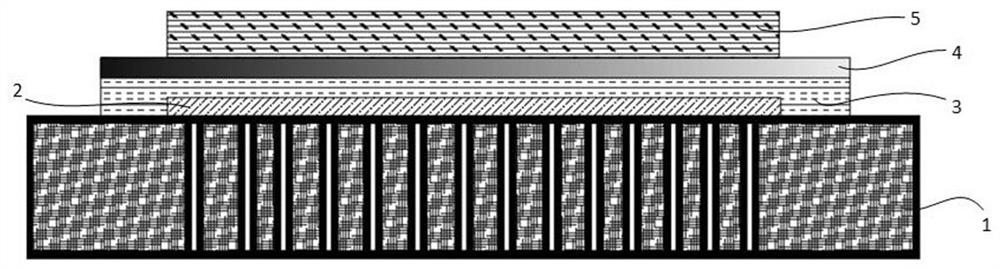

[0083] S101. Provide an anode substrate, the anode substrate includes a metal support and a fuel electrode layer on the metal support, wherein the metal support has a porous region, and a protective coating arranged along the outer surface of the metal support and the porous inner wall of the porous region , the fuel electrode layer covers the porous area.

[0084] S102. Use magnetron sputtering to sputter the barrier layer on the anode substrate. The substrate of the YSZ barrier layer can be YSZ. YSZ uses Y / Zr alloy as the target material, adopts the direct current (DC) sputtering mode, and controls the sputtering power DC as 100W, gas selection O 2 Mixed gas with Ar, O 2 The gas ratio to Ar is 1 / 2, the gas flow rate is 10sccm, the chamber pressure is 8Pa, the bias voltage is -10V, the substrate temperature is 300°C, the substrate rotation speed is 15pm, the distance between the substrate and the target is 2cm, and the sputtering time is 40min. The thickness of the barrier ...

Embodiment 2

[0087] S101. Provide an anode substrate, the anode substrate includes a metal support and a fuel electrode layer on the metal support, wherein the metal support has a porous region, and a protective coating arranged along the outer surface of the metal support and the porous inner wall of the porous region , the fuel electrode layer covers the porous area.

[0088] S102. Use magnetron sputtering to sputter the barrier layer on the anode substrate. The substrate of the YSZ barrier layer can be SSZ. SSZ uses Sc / Zr alloy as the target material, adopts the direct current (DC) sputtering mode, and controls the sputtering power DC as 100W, gas selection O 2 Mixed gas with Ar, O 2 The gas ratio to Ar is 1 / 2, the gas flow rate is 10sccm, the chamber pressure is 8Pa, the bias voltage is -100V, the substrate temperature is 400°C, the substrate rotation speed is 15pm, the distance between the substrate and the target is 2cm, and the sputtering time is 20min. The thickness of the barrie...

Embodiment 3

[0091] S101. Provide an anode substrate, the anode substrate includes a metal support and a fuel electrode layer on the metal support, wherein the metal support has a porous region, and a protective coating arranged along the outer surface of the metal support and the porous inner wall of the porous region , the fuel electrode layer covers the porous area.

[0092] S102. Use magnetron sputtering to sputter the barrier layer on the anode substrate. The barrier layer substrate can be YSZ. YSZ uses YSZ ceramic material as the target material, adopts radio frequency (RF) sputtering mode, and controls the sputtering power RF to 100W. Gas selection O 2 Mixed gas with Ar, O 2 The gas ratio to Ar is 1 / 20, the gas flow rate is 10sccm, the chamber pressure is 8Pa, the substrate temperature is room temperature, the substrate rotation speed is 15pm, the distance between the substrate and the target is 2cm, the sputtering time is 2h, and the thickness of the barrier layer is 500nm;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com