Chitosan microcapsule modified acrylic bone cement and preparation method thereof

A technology of chitosan microcapsules and acrylic acid, which is applied in the field of medical biomaterials and can solve problems such as the decline in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

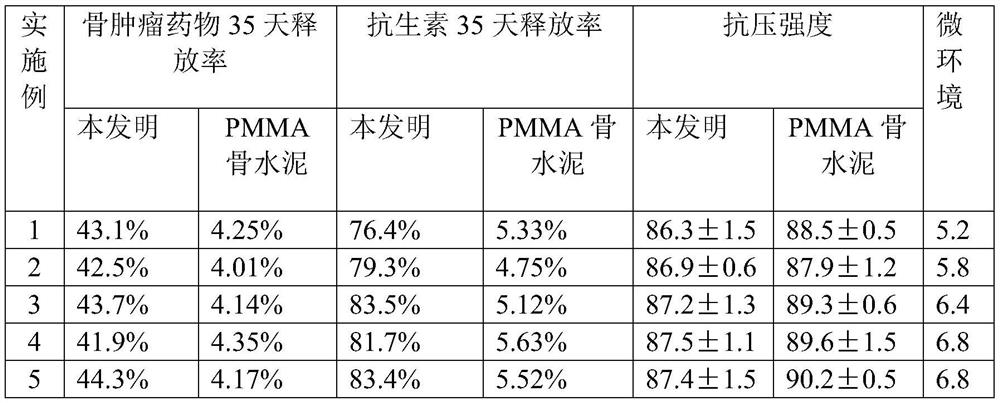

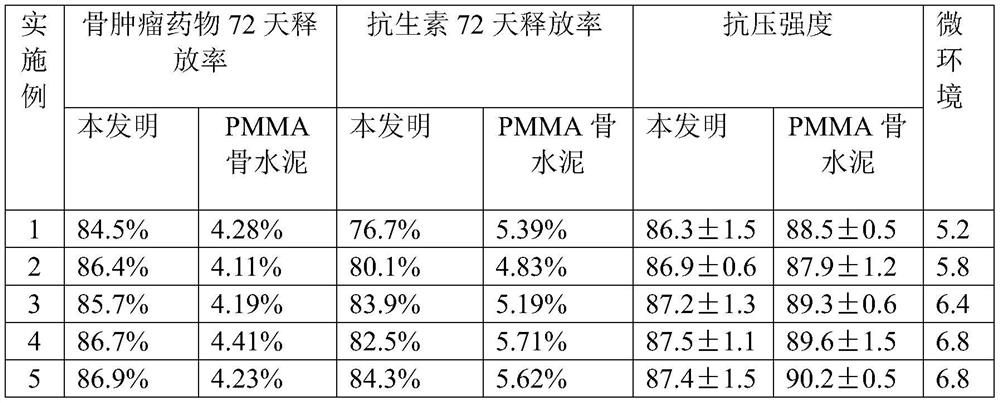

Examples

Embodiment 1

[0060] A kind of preparation method of chitosan microcapsule modified acrylic acid bone cement of the present invention comprises the following steps:

[0061] Step 1, preparing chitosan microcapsules loaded with methotrexate;

[0062] Step 1.1, 2g chitosan is dissolved in the acetic acid solution of 100ml1wt%, obtains the chitosan solution that concentration is 2wt% after mechanical stirring, ultrasonic defoaming as shell layer, 1.5g methotrexate is dissolved in 100ml to remove In deionized water, after stirring evenly, a methotrexate solution with a concentration of 1.5wt% is obtained as a nuclear layer spinning solution precursor;

[0063] Step 1.2, the acetic acid solution of chitosan is placed in syringe 1, and the aqueous drug solution is placed in syringe 2, and at a push speed ratio of 2 to 1 and a voltage of 15KV, push to T=30°C, 5wt% NaOH and 1wt% %Na 2 SO 4 coagulated in ethanol solution, and freeze-dried to obtain chitosan microcapsules loaded with bone tumor dr...

Embodiment 2

[0071] A kind of preparation method of chitosan microcapsule modified acrylic acid bone cement of the present invention comprises the following steps:

[0072] Step 1, preparation of loaded bortezomib chitosan microcapsules

[0073] Step 1.1, 4g chitosan is dissolved in 100ml 1wt% acetic acid solution, after mechanical stirring, ultrasonic degassing, obtain the chitosan solution that concentration is 4wt% as shell layer, 2g bortezomib is dissolved in 100ml deionized water After stirring evenly, a bortezomib solution with a concentration of 2wt% was obtained as the precursor of the nuclear layer spinning solution;

[0074] Step 1.2, the acetic acid solution of chitosan is placed in syringe 1, and the aqueous drug solution is placed in syringe 2, and the pushing speed ratio is 3 to 1, and the voltage is 17KV, pushing to T=30°C, 5wt% NaOH and 1wt% %Na 2 SO 4 The chitosan microcapsules loaded with bone tumor drugs were obtained after freeze-drying in ethanol solution.

[0075]...

Embodiment 3

[0082] A kind of preparation method of chitosan microcapsule modified acrylic acid bone cement of the present invention comprises the following steps:

[0083]Step 1, prepare chitosan microcapsules loaded with doxorubicin

[0084] Step 1.1, dissolve 3g of chitosan in 100ml of 1wt% acetic acid solution, obtain a concentration of 3wt% chitosan solution as the shell layer after mechanical stirring and ultrasonic degassing, and dissolve 2g of doxorubicin in 100ml of deionized water After stirring evenly, a doxorubicin solution with a concentration of 2wt% was obtained as the precursor of the nuclear layer spinning solution;

[0085] Step 1.2, the acetic acid solution of chitosan is placed in syringe 1, and the aqueous drug solution is placed in syringe 2, and at a push speed ratio of 3 to 1 and a voltage of 23KV, push to T=30°C, 5wt% NaOH and 1wt% %Na 2 SO 4 The chitosan microcapsules loaded with bone tumor drugs were obtained after freeze-drying in ethanol solution.

[0086] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com